Need precise parts but CAD software costs are high? This limits your projects. Free tools offer a great solution.

Yes, several powerful free CAD tools are excellent for CNC machining in 2025. Options like FreeCAD, Onshape Free Plan, and Fusion 360 Personal Use provide robust features without the hefty price tag, helping you create amazing designs.

Finding the right free CAD software can feel overwhelming. Many options exist. Each has its strengths and weaknesses, especially for CNC machining. I’ve spent years working with different tools and helping clients at QuickCNCs. So, I want to share my insights. Let’s look at some of the best choices for 2025. This will help you pick the right one for your projects. I believe this guide will be very useful for engineers like Alex, who need reliable tools for precision work.

Is Tinkercad a Good Starting Point for CNC Beginners?

New to CAD and CNC? Complex software can be scary. Tinkercad offers a simple, friendly way to start designing.

Absolutely. Tinkercad is very easy to learn. It’s great for beginners creating basic 3D models for CNC, especially for simpler projects or educational purposes, getting you started quickly.

| Dive deeper Paragraph: Tinkercad is a free, online 3D modeling program. Autodesk, the company behind AutoCAD and Fusion 360, runs it. It’s known for its simple interface and ease of use. You use basic shapes like cubes, cylinders, and spheres. You combine them to create more complex models. This makes it very intuitive. I remember when I first showed Tinkercad to a client for a quick, non-critical part. They were able to mock up their idea within an hour, which was impressive. For CNC machining, you can easily export your designs as STL files. Many CAM programs can then use these STL files to generate G-code. However, Tinkercad is not ideal for highly complex or precise mechanical parts requiring tight tolerances. It lacks advanced features like parametric modeling and detailed dimensioning tools found in more professional software. So, if you need parts with ±0.01mm accuracy like Alex often does, Tinkercad might not be the primary tool. But for learning the basics of 3D design, rapid prototyping of simple forms, or hobbyist CNC projects, it’s a fantastic choice. Its simplicity is its biggest strength for newcomers. |

Feature | Detail |

|---|---|---|

| Ease of Use | Very high, beginner-friendly | |

| Platform | Web-based | |

| Best For | Simple 3D models, education, hobbyists | |

| CNC Export | STL, OBJ, SVG | |

| Limitations | Not for complex or high-precision parts |

Can SketchUp Free Handle Your Simpler 3D CNC Designs?

Want easy 3D modeling for less complex parts? SketchUp Free is intuitive. But is it good enough for CNC tasks?

Yes, SketchUp Free is useful for simpler 3D designs, especially in woodworking or architectural models that might be CNC’d. It’s user-friendly, but precision can be a challenge for mechanical parts.

| SketchUp Free is another web-based 3D modeling tool. It’s well-known for its ease of use, particularly in architectural and interior design. I’ve seen many designers use it for quick visualizations. Its push-pull tool is very intuitive for creating 3D shapes from 2D faces. For CNC machining, SketchUp Free can export STL files, which are common for 3D printing and some CNC workflows. It’s quite capable for projects where absolute precision isn’t the top priority, like artistic carvings or custom furniture parts. However, its free version has limitations. It’s not truly parametric, which means making changes to complex designs can be time-consuming. For engineers like Alex, who work with high-tolerance mechanical components, SketchUp Free might feel a bit loose. Achieving the kind of precision needed for interlocking metal parts can be tricky. I once tried to use it for a jig design, and while I got it done, maintaining exact dimensions was more work than in a parametric modeler. It’s a great tool for visualization and simpler forms, but for serious mechanical CNC work, you might hit its limits quickly. | Feature | Detail |

|---|---|---|

| Ease of Use | High, intuitive interface | |

| Platform | Web-based | |

| Best For | Architectural, woodworking, conceptual design | |

| CNC Export | STL (via extension in desktop versions) | |

| Limitations | Not parametric, precision challenges for mechanical parts |

Is LibreCAD a Viable Option for 2D CNC Machining?

Need to create 2D designs for your CNC machine? LibreCAD is free and open-source. But does it deliver for CNC?

Yes, LibreCAD is a solid choice for 2D CAD tasks. It’s excellent for creating DXF files used in laser cutting, plasma cutting, and 2D milling operations, offering essential drafting tools.

| LibreCAD is a completely free, open-source 2D CAD application. It runs on Windows, macOS, and Linux. If you’re familiar with AutoCAD’s 2D drafting, you’ll find LibreCAD’s interface somewhat similar, though simpler. Its main strength is creating precise 2D drawings, which are crucial for many CNC processes. I often recommend it to clients who need to produce DXF files for laser cutters or 2D router profiles. It supports layers, blocks, and various drawing tools like lines, arcs, circles, and polylines. For engineers preparing profiles for sheet metal bending or parts that will be cut from flat stock, LibreCAD is very capable. The key thing to remember is that LibreCAD is strictly 2D. It cannot create 3D models. So, if your CNC project involves 3-axis or 5-axis milling of complex 3D shapes, you’ll need a different tool. But for many workshops, a lot of work starts with accurate 2D geometry. I’ve used it myself for quick sketches of custom mounting plates before moving to a 3D tool for verification. It’s lightweight and gets the job done for 2D tasks without any cost. | Feature | Detail |

|---|---|---|

| Ease of Use | Moderate, some CAD experience helpful | |

| Platform | Desktop (Windows, macOS, Linux) | |

| Best For | 2D drafting, DXF files for laser/plasma/routing | |

| CNC Export | DXF, DWG (limited support) | |

| Limitations | Strictly 2D, no 3D modeling capabilities |

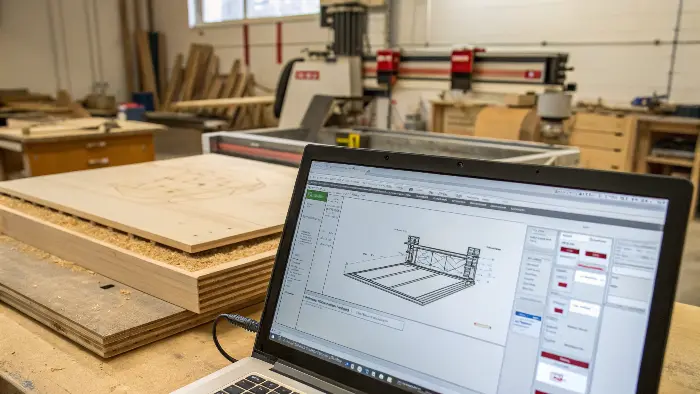

Is FreeCAD Powerful Enough for Complex CNC Projects?

Searching for a robust, free parametric modeler? FreeCAD is a strong contender. But can it handle demanding CNC work effectively?

Yes, FreeCAD is a very capable open-source parametric 3D modeler. It’s suitable for designing complex mechanical parts for CNC machining, offering features comparable to commercial software.

| FreeCAD is a highly versatile, open-source parametric 3D modeler. "Parametric" means you design parts based on parameters and constraints, making it easy to modify designs by changing values. This is essential for iterative design, which Alex, our engineer profile, does a lot. FreeCAD has a modular architecture with different "workbenches" for specific tasks, like Part Design, Sketcher, Draft, and even a Path workbench for CAM (generating G-code). I’ve seen FreeCAD used for some impressively complex mechanical assemblies. Its learning curve can be steeper than simpler tools, but the capabilities are significant for a free program. You can create detailed 3D models and then generate 2D technical drawings from them. For CNC, you can export models in formats like STEP and IGES, which are industry standards for transferring 3D data. The Path workbench allows you to define toolpaths directly within FreeCAD, though many users prefer dedicated CAM software. I recall a project where a startup client used FreeCAD exclusively to design and prepare parts for CNC milling due to budget constraints. They were successful, but it took dedication to master the tool. The community support is active, which is helpful when you encounter challenges. | Feature | Detail |

|---|---|---|

| Ease of Use | Moderate to High, learning curve involved | |

| Platform | Desktop (Windows, macOS, Linux) | |

| Best For | Parametric 3D modeling, mechanical design | |

| CNC Export | STEP, IGES, STL, DXF, integrated CAM (Path Workbench) | |

| Limitations | Steeper learning curve, UI can feel less polished than commercial tools |

Can Blender Be Used Effectively for CNC Design Work?

Blender is famous for animation and sculpting. But can this free powerhouse be adapted for precise CNC machining tasks?

Yes, with effort. Blender is primarily for artistic 3D modeling. While it can export meshes for CNC, achieving engineering precision for mechanical parts is challenging but possible for organic shapes.

| Blender is an incredibly powerful, free, and open-source 3D creation suite. It excels at modeling, sculpting, animation, rendering, and more. Many artists and designers use it for creating organic shapes, characters, and visual effects. When it comes to CNC, Blender can be used, especially for more artistic or sculptural pieces. You can create intricate 3D meshes and export them as STL or OBJ files for your CAM software. I know a designer who uses Blender to create custom molds with complex, flowing surfaces that are then CNC milled. However, Blender is not a traditional CAD program. It’s a mesh modeler, not a parametric solid modeler by default (though addons can add some CAD-like functionality). This means achieving the high dimensional accuracy and maintaining design intent for mechanical parts, like those Alex designs, can be very difficult. The workflow is different from CAD software; it’s less about precise dimensions and constraints and more about artistic form. For engineers needing exact measurements and easy modifications, Blender’s learning curve for precision work is very steep. If your CNC projects involve artistic carvings, sculptures, or complex organic forms where absolute precision is secondary to aesthetics, Blender can be a fantastic free tool. | Feature | Detail |

|---|---|---|

| Ease of Use | Very high learning curve for CAD-like precision | |

| Platform | Desktop (Windows, macOS, Linux) | |

| Best For | Artistic modeling, sculpting, organic shapes | |

| CNC Export | STL, OBJ | |

| Limitations | Not a traditional CAD program, difficult for precise mechanical parts |

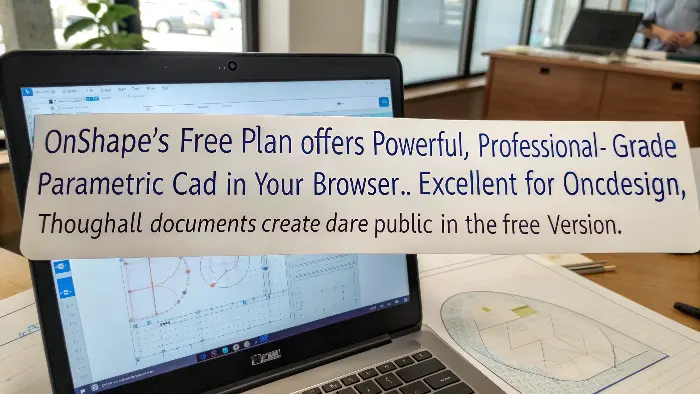

Is Onshape’s Free Plan a Good Cloud-Based CAD Solution for CNC?

Want modern, cloud-based CAD with collaboration features? Onshape’s Free Plan is attractive. But what are its limits for CNC?

Yes, Onshape’s Free Plan offers powerful, professional-grade parametric CAD in your browser. It’s excellent for CNC design, though all documents created are public in the free version.

| Onshape is a full-cloud CAD platform, meaning it runs entirely in your web browser. There’s nothing to install. It was developed by some of the founders of SolidWorks, so it has a strong pedigree in parametric 3D modeling. The Free Plan (or Public Plan) gives you access to almost all of Onshape’s powerful modeling features, including part design, assemblies, and drawings. This is fantastic for individuals and hobbyists. I am particularly impressed by its collaboration tools and built-in version control, which are great for team projects, even on the free tier. For CNC machining, Onshape can export standard formats like STEP, IGES, STL, and DXF. The main "catch" with the Free Plan is that all documents you create are publicly accessible. This might be a deal-breaker if you’re working on proprietary designs. However, for open-source projects, learning, or non-sensitive work, it’s an amazing resource. I’ve recommended it to engineers who want to try a modern CAD system without upfront costs. The performance in the browser is surprisingly good, even with complex assemblies. If privacy isn’t a concern for a specific project, Onshape Free Plan is a top-tier choice for serious CNC design work. | Feature | Detail |

|---|---|---|

| Ease of Use | Moderate, similar to other professional CAD | |

| Platform | Web-based | |

| Best For | Parametric 3D modeling, collaboration, learning | |

| CNC Export | STEP, IGES, STL, DXF | |

| Limitations | All documents are public in the free plan |

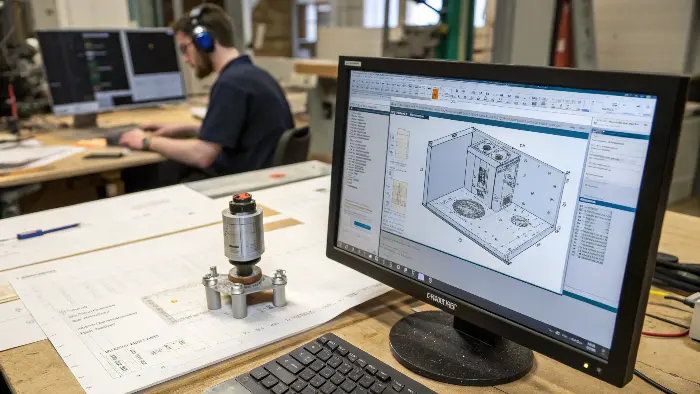

Can Fusion 360 for Personal Use Meet Your Advanced CNC Needs?

Need integrated CAD and CAM on a budget? Fusion 360 for Personal Use is powerful. But are the free version’s limitations too restrictive?

Yes, Fusion 360 for Personal Use is an excellent, comprehensive tool for CNC. It combines CAD, CAM, and CAE, though the free license has limitations on some advanced features and commercial use.

| Autodesk Fusion 360 is an incredibly popular cloud-based platform that integrates CAD, CAM, CAE, and PCB design. The "for Personal Use" license makes much of this power available for free to hobbyists, startups (with revenue limits), and individuals for non-commercial projects. I find Fusion 360’s user interface to be quite intuitive, and it offers robust parametric modeling, freeform modeling, and assembly capabilities. A huge advantage for CNC users is the integrated CAM. You can design your part and then, within the same software, define toolpaths, simulate machining, and generate G-code for your CNC machine. This streamlined workflow is a significant time-saver. I’ve helped many small businesses and startups get going with Fusion 360. The personal use license has some restrictions, such as a limit on the number of active editable documents (currently 10), and some advanced CAM strategies (like 5-axis simultaneous milling) might be limited or unavailable. File export options might also be restricted compared to the paid version. However, for 2.5-axis and 3-axis CNC machining, it’s extremely capable. It’s a fantastic way to access professional-level tools for your personal CNC projects. Always check Autodesk’s current terms for the personal use license, as they can change. | Feature | Detail |

|---|---|---|

| Ease of Use | Moderate, comprehensive but well-structured | |

| Platform | Cloud-enabled Desktop (Windows, macOS) | |

| Best For | Integrated CAD/CAM, parametric modeling, hobbyists, startups | |

| CNC Export | STEP, IGES, STL, DXF, direct G-code generation (CAM) | |

| Limitations | Restrictions on active documents, some advanced CAM, commercial use under free license. |

LOOP END

Conclusion

Choosing the right free CAD tool boosts your CNC projects. Evaluate these options based on your specific design needs and skills.