Precision CNC Machining Services from China

High-quality custom CNC parts delivered worldwide — fast, accurate, and affordable.

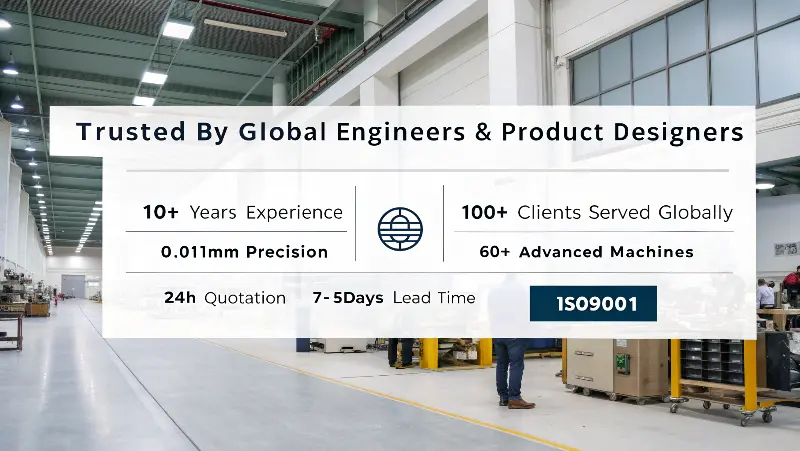

Company Highlights

Trusted by Global Engineers & Product Designers

🏭 10+ Years Experience

🌍 100+ Clients Served Globally

🎯 ±0.01mm Tolerance

🛠️ 60+ Advanced Machines

⏱️ 24h Quotation | 7-15 Days Lead Time

🔧 ISO9001 Certified

Services Section

Our Core CNC Machining Services

CNC Milling

CNC Turning

EDM / Wire Cutting

Surface Grinding

Rapid Prototyping

Small Batch Production

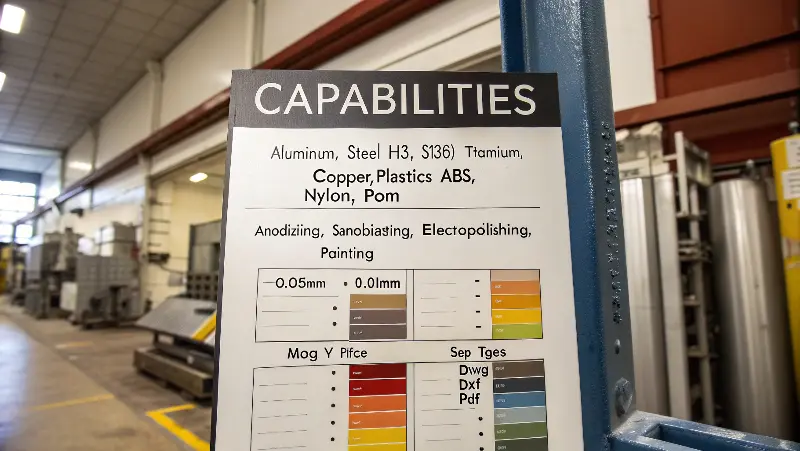

Capabilities Section

Materials Supported: Aluminum, Steel (H13, S136), Titanium, Copper, Plastics (ABS, Nylon, POM…)

Surface Finishes: Anodizing, Sandblasting, Electropolishing, Painting, etc.

Part Size: 1500 x 1000 x 250mm

Tolerance Range: ±0.005mm – ±0.01mm

MOQ: 1 Piece

Supported Files: STEP, IGES, DWG, DXF, PDF

Industries We Serve

🚗 Automotive

📱 Consumer Electronics

🏥 Medical Devices

🛫 Aerospace

🤖 Robotics

⛽ Industrial Equipment

Why Choose Us

Why Engineers Love Working with QuickCNCs

On-Time Delivery

Transparent Quoting

Design for Manufacturing (DFM) Guidance

Real-Time Project Updates

Free Samples for Long-Term Clients

NDA Protection

Testimonials

FAQ Section

🟢 Answer:

Lead time depends on part complexity, quantity, and surface treatment requirements.

Prototype parts: usually 3–7 working days

Small batch orders: 7–15 working days

Mass production: 15–30 working days

We always confirm the delivery time during the quotation process.

🟢 Answer:

We support a wide range of metals and plastics, including but not limited to:

Metals: Aluminum (6061, 7075), Steel (H13, 4140, S136, 420SS), Brass, Copper, Stainless Steel, Titanium

Plastics: POM, ABS, PC, Nylon (PA6/PA66), PEEK, PTFE, PMMA, and more

If you need material certification (e.g., RoHS, REACH), we can provide it upon request.

🟢 Answer:

We follow strict in-house quality control procedures at each stage of production:

Incoming material inspection

In-process quality checks

Final dimension inspection before shipping

We use precision measuring tools such as CMM, height gauges, micrometers, and calipers. ISO 9001 and TS16949 quality standards are followed throughout our process.

🟢 Answer:

Yes, we provide full inspection reports upon request, including:

Dimensional reports (with tolerance checks)

Material certificates

Surface finish verification

First Article Inspection (FAI) if required

🟢 Answer:

Absolutely. We highly recommend starting with a prototype or sample to validate dimensions and functionality. Once the sample is approved, we proceed with bulk production. Samples can typically be delivered within 5–7 working days.