Struggling with production bottlenecks or high scrap rates? Wondering if new fixtures are worth the investment? Understanding the true return on investment can provide clear answers.

Advanced CNC fixturing offers significant ROI by reducing setup times, labor costs, and material waste, while boosting production output and part quality. Calculating this ROI helps you make informed investment decisions for your workshop.

I often talk to engineers like Alex who are under pressure to improve efficiency and cut costs. They know their current workholding might be holding them back, but the upfront cost of advanced fixtures can seem daunting. The key is to look beyond that initial price tag and understand how to measure the real financial impact. It’s about making a data-driven decision, not just a gut feeling. Let’s explore how you can determine if it’s the right time for your shop to invest.

How Do I Even Begin to Calculate the ROI for New Fixtures?

Thinking about new fixtures, but unsure how to justify the cost? It feels complex, with many factors to consider. Start by identifying key variables for a clear financial picture.

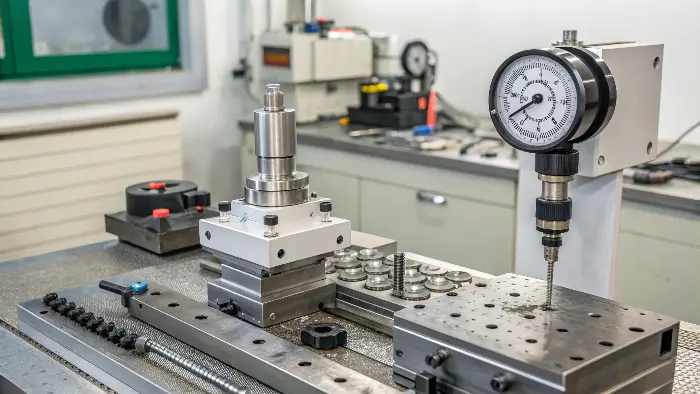

To calculate fixturing ROI, input specific variables like labor costs, current vs. projected output, cycle times, material waste rates, and potential energy or maintenance savings into a systematic evaluation or an ROI calculator.

Calculating the return on investment for advanced CNC fixturing isn’t just a vague idea; it can be a very concrete process. I’ve seen companies, like one I read about that developed an ROI calculator for their automation solutions, help workshops put real numbers to potential savings. You need to look at your unique situation. Think about your current processes and where the pain points are. For instance, if Alex is spending hours on setups for high-tolerance parts, that’s a big factor.

Here are the key areas I always advise people to look at:

- Labor Costs: How much time do your operators spend setting up jobs with your current fixtures? Think about direct labor. Advanced fixtures, especially custom or quick-change systems, can drastically reduce this.

- Production Output: How many parts are you making per shift or per day? Could faster setups or the ability to hold multiple parts at once increase this?

- Cycle Time: This is the total time to produce one part. Better fixtures often allow for more aggressive machining parameters due to increased rigidity, directly cutting down the machining time.

- Material Waste: How many parts are scrapped due to poor positioning, vibration, or deflection with your current setup? Precision workholding significantly improves consistency.

- IoT Insights (if applicable): If you’re looking at ‘smart’ fixtures or integrated automation, what data can they provide to further optimize processes? This is a newer area but offers great potential.

- Energy and Maintenance: While maybe not the biggest factor, more efficient machining due to stable workholding can lead to slightly lower energy use per part and less wear and tear on your machine tool.

By gathering data on these points for your current state, you can then project the improvements with advanced fixturing and see a clearer financial picture.Can Better Fixtures Really Cut Down My Labor Costs and Speed Up Production?

Are lengthy setups and slow cycle times eating into your profits? You need faster throughput but are unsure if new fixtures are the answer. Yes, good fixturing directly impacts speed and labor.

Advanced fixtures slash labor costs by simplifying and speeding up setups. They also boost production by enabling faster cycle times, multi-part machining, and reduced machine downtime, directly increasing overall output.

Let’s talk about labor costs and production speed, because these are often the first places engineers like Alex see big improvements. I remember visiting a shop that was making complex aerospace components. Their setup times were incredibly long with their old, generic fixtures. They were manually shimming and indicating every single part. When they switched to custom hydraulic workholding designed specifically for their parts, the change was dramatic. Setup time for a job went from several hours down to under 30 minutes.

Here’s how this happens: - Reduced Setup Time: This is a huge one. Think about dedicated fixtures, modular systems, or quick-change pallet systems. Operators can swap jobs much faster. If a setup that took 2 hours now takes 20 minutes, that’s 1 hour and 40 minutes of labor saved, and more importantly, that’s 1 hour and 40 minutes the machine is now making parts instead of sitting idle. For Alex, who manages multiple prototype revisions, this speed is invaluable.

- Faster Cycle Times: A really secure and rigid fixture allows you to machine more aggressively. You can often increase feed rates and depths of cut without worrying about the part moving or excessive vibration. This directly shortens the in-cut time per part. Even a 10-15% reduction in cycle time adds up significantly over hundreds or thousands of parts.

- Multi-Part Machining: Custom fixtures are often designed to hold multiple parts at once. So, instead of machining one part, the machine completes two, four, or even more in a single cycle. This drastically increases throughput without needing more machines or operators for that specific step.

- Less Operator Intervention: With reliable and repeatable workholding, operators spend less time monitoring the machine, making adjustments, or checking parts. This frees them up for other valuable tasks, like preparing the next job or performing quality checks.

When you add up these time savings, the impact on your labor costs per part and your overall production capacity can be quite substantial. It’s not just about saving a few minutes here and there; it’s about fundamentally changing how efficiently your machines operate.Will Investing in Advanced Workholding Reduce My Material Waste and Improve Quality?

Scrapping parts due to poor tolerances or movement during machining is costly and frustrating. You need consistency and precision. Advanced fixtures are key to achieving both.

Yes, superior workholding directly reduces material waste and improves part quality by ensuring consistent, accurate positioning and minimizing vibration, leading to fewer rejects and less rework for tight-tolerance parts.

Material waste and part quality are critically important, especially for someone like Alex who works with high-tolerance robotic components where precision is everything (±0.01mm or better). Every scrapped part isn’t just lost material; it’s lost machine time, lost labor, and potentially a delayed project. I’ve seen firsthand how inadequate fixturing can lead to a pile of expensive scrap.

Here’s how advanced workholding makes a difference: - Improved Positional Accuracy and Repeatability: Good fixtures locate the part precisely and consistently every single time. This is fundamental for achieving tight tolerances. If your fixture allows even tiny variations in part positioning from one piece to the next, holding those tolerances becomes a constant battle. Custom fixtures, especially those using dowel pins, precision locators, or hydraulic clamping, provide excellent repeatability.

- Reduced Vibration and Deflection: Vibration is the enemy of precision machining. A flimsy or poorly designed fixture will allow the part or the fixture itself to vibrate during cutting. This leads to poor surface finish, dimensional inaccuracies, and can even cause tool breakage. Advanced fixtures are designed for maximum rigidity, damping vibration and ensuring the part stays perfectly still, even under heavy cutting loads. This is crucial for Alex’s components.

- Fewer Rejects and Less Rework: When parts are held securely and located accurately, the number of parts that fail quality inspection drops dramatically. This means less material waste from scrapped parts and less time spent on costly rework operations. The goal is to get it right the first time, every time.

- Consistent Quality Across Batches: With reliable fixturing, you can be confident that the first part in a batch will be just as good as the last. This consistency is vital for maintaining customer satisfaction and your reputation for quality.

Investing in a fixture that provides robust support and precise location pays for itself quickly by minimizing scrap and ensuring your parts meet specification without constant headaches. For Alex, who needs to avoid material waste and ensure quality, this is a major benefit.What Are the Less Obvious, Long-Term Financial Benefits of Upgraded Fixtures?

Beyond immediate savings, are there other financial upsides to better fixtures? You might be focused on short-term ROI. Consider the extended advantages like durability and data potential.

Long-term benefits include increased machine tool life due to reduced stress, lower fixture maintenance if well-made, and potential for data collection from ‘smart’ fixtures, contributing to ongoing process optimization and cost savings.

When we talk about ROI, it’s easy to focus on the immediate, easily quantifiable savings like reduced labor or less scrap. But I always encourage people to think about the less obvious, long-term financial benefits that quality fixturing brings to the table. These might not show up on a simple ROI calculation in the first few months, but they add significant value over the life of the fixture and your machine tool. - Increased Machine Tool Life: This is a big one. A rigid, well-designed fixture that damps vibration doesn’t just protect the workpiece; it also protects your expensive CNC machine. Excessive vibration and chatter put a lot of stress on machine spindles, bearings, and ways. Over time, this can lead to premature wear and tear, requiring more frequent and costly machine maintenance or even an earlier machine replacement. Good fixturing acts like a shock absorber, leading to smoother operation and a longer, healthier life for your machine.

- Lower Fixture Maintenance/Replacement Costs: A cheap, poorly made fixture might save you money upfront, but it will likely wear out faster, require more frequent repairs, or lose its accuracy. Investing in a high-quality, durable fixture made from good materials and to precise standards means it will last longer and maintain its performance with minimal upkeep. This means fewer replacement costs and less downtime associated with fixing or replacing worn-out workholding.

- Potential for IoT Integration and Data Insights: This is where things get really interesting for future-focused shops. Some advanced fixturing solutions are now being designed with integrated sensors. These "smart fixtures" can provide real-time data on things like clamping force, part presence, or even temperature. This data can be fed into your manufacturing execution system (MES) or an IoT platform. As the insights mentioned, "IoT insights: include real-time data from smart automation systems." This data can be invaluable for process monitoring, predictive maintenance, and continuous improvement efforts, leading to further efficiencies and cost savings down the line. It helps you understand exactly what’s happening at the point of machining.

These long-term benefits might take a bit more effort to quantify initially, but they are very real and contribute to a lower total cost of ownership and a more robust, efficient manufacturing operation.Conclusion

Investing in advanced CNC fixturing offers clear financial returns by boosting efficiency, quality, and output. Analyzing your specific needs and potential savings will show you when it’s right.