Struggling to choose the right CAM software for your specific industry needs? The options seem endless, causing confusion. Understanding key CAM tools helps ensure efficient, precise CNC machining for your projects.

CAM software translates CAD designs into machine instructions (G-code) for CNC machines. Popular choices include Mastercam, Fusion 360, SolidCAM, and Esprit, each with strengths for different machining tasks and industries, impacting precision and efficiency.

Transition Paragraph:

I’ve spent years on the shop floor and now help engineers like Alex source precision parts globally. One question that often comes up is about the software that turns a brilliant design into a physical component. It’s a critical step, and the right Computer-Aided Manufacturing (CAM) software can make all the difference in terms of quality, speed, and cost. Many engineers are experts in CAD (Computer-Aided Design) but might not be as familiar with the nuances of CAM. At QuickCNCs, we work with various CAM systems to best suit the job, and I want to share some insights to help you understand this crucial part of the manufacturing puzzle. Let’s explore what these tools are and how they fit into the world of precision CNC machining.

What Software is Used for CAM, and How Does It Work with CAD?

Confused about how your digital CAD designs become real, tangible parts? The CAM software might seem like a complex black box. It’s actually the essential bridge that makes your digital designs manufacturable with precision.

CAM (Computer-Aided Manufacturing) software takes 3D CAD models as input. It then helps engineers and programmers create the specific toolpaths and generate the G-code instructions that CNC machines understand and follow to cut the part accurately.

The journey from a design concept to a finished machined part almost always starts with a CAD model. Engineers like Alex spend a lot of time perfecting these models in software like SolidWorks, AutoCAD, Inventor, or Catia. But the CAD file itself doesn’t tell a CNC machine how to make the part. That’s where CAM software steps in. Think of it as a translator and a strategist. It imports the CAD model (often in formats like STEP, IGES, or native CAD files) and provides a platform to define the manufacturing process. This includes selecting the right cutting tools, setting cutting speeds and feeds, and determining the optimal path the tool will take to remove material – these are the toolpaths. Good CAM software also offers simulation capabilities, allowing us to watch a virtual machining process. This helps catch potential collisions or errors before any metal is cut, saving time and material. At QuickCNCs, we rely on robust CAM systems because they are foundational to delivering the precision and efficiency our clients expect for their custom metal and plastic parts. There are standalone CAM packages and some that are integrated directly into CAD software, offering a seamless transition from design to manufacturing preparation.

What is the Main Use of CAM Software for Writing CNC Programs?

Manually writing G-code for complex parts with many features is incredibly time-consuming and highly prone to errors. CAM software offers a much more efficient and reliable way to generate these crucial machine instructions.

CAM software’s primary use is to automate the creation of CNC programs, commonly known as G-code. It analyzes the part’s geometry from the CAD model and generates optimized toolpaths and corresponding G-code for efficient and accurate machining.

Back when I started in a CNC shop, for very simple parts, sometimes G-code was written manually, line by line. But for anything even moderately complex, and certainly for the intricate components Alex designs for robotics, manual G-code programming is impractical. Imagine trying to calculate thousands of X, Y, and Z coordinates for a smooth contoured surface – it would take ages and be a recipe for mistakes. CAM software automates this. It interprets the 3D geometry of the part and, based on the manufacturing strategies defined by the programmer, generates the sequence of G-code commands. These commands tell the CNC machine exactly where to move the tool, how fast to move it, when to turn coolant on or off, and when to change tools. Advanced CAM systems can create highly optimized toolpaths, like high-speed machining (HSM) routines, that remove material faster and extend tool life. The simulation feature is also vital here; it graphically shows the material removal process, allowing us to verify that the G-code will produce the part as intended, without gouging or leaving excess material. This dramatically reduces the risk of scrapping expensive material or damaging the machine. The time saved and accuracy gained by using CAM for G-code generation are immense.

What Software is Actually Used on the CNC Machine Itself?

Does the CAM software run directly on the CNC machine that’s cutting the metal? This is a common point of curiosity for many. The CNC machine has its own specialized control software that interprets the output from the CAM system.

CNC machines run on their own dedicated control software, often from manufacturers like Fanuc, Siemens, Haas, or Mazak. CAM software generates the G-code, which is then loaded into this machine controller to execute the machining operations.

It’s important to understand the distinction: CAM software is an offline programming tool used on a computer, typically in an engineering office or programming department. The CNC machine tool on the shop floor has its own embedded computer and software, which is called the CNC controller. This controller is the brain of the machine. The G-code program generated by the CAM software is essentially a text file containing specific instructions. This file is transferred to the CNC machine’s controller (via USB, Ethernet, or older methods like RS-232). The controller then reads and interprets this G-code line by line, translating those commands into precise electrical signals that drive the machine’s motors, spindles, and other components.

A critical component within the CAM software is the "post-processor." Each brand and model of CNC controller can have slight variations in how it interprets G-code or supports specific functions. The post-processor in the CAM system tailors the G-code output to be perfectly compatible with the target CNC machine. This is vital for ensuring that the machine behaves exactly as intended by the CAM program. For Alex, who needs tight tolerances, a correctly configured post-processor ensures that the precision programmed in CAM is accurately realized on the machine.

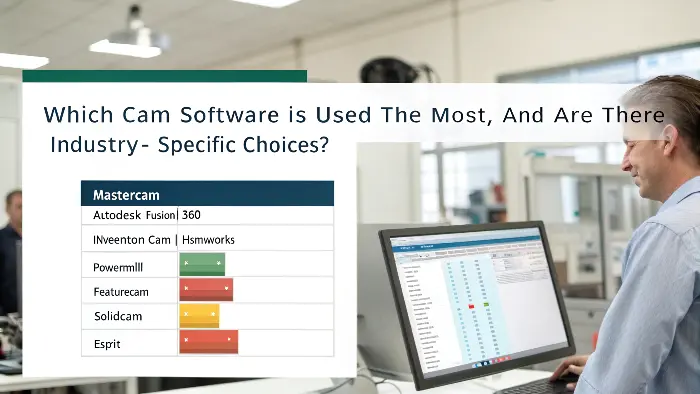

Which CAM Software is Used the Most, and Are There Industry-Specific Choices?

Overwhelmed by the sheer number of CAM software options available on the market? Choosing the right one for your specific needs can feel like a daunting task. Certain CAM packages are widely adopted industry leaders, while others excel in specialized niches.

Mastercam, Autodesk’s suite (Fusion 360, Inventor CAM/HSMWorks, PowerMill, FeatureCAM), SolidCAM, and Esprit are among the most widely used CAM software. Many offer specialized modules or strengths tailored for industries like aerospace, automotive, or medical device manufacturing, catering to specific precision machining requirements.

There isn’t a single "best" CAM software for everyone; the ideal choice often depends on the complexity of the parts, the types of CNC machines being used, specific industry requirements, and budget.

- Mastercam is perhaps the most widely used CAM software globally, known for its comprehensive capabilities from 2-axis turning and 3-axis milling to complex 5-axis and mill-turn applications. It’s a robust all-rounder.

- Autodesk offers a strong portfolio. Fusion 360 is popular for its integrated CAD/CAM/CAE environment, cloud collaboration, and accessibility, making it great for startups and product developers. Inventor CAM (formerly HSMWorks) provides a deeply integrated experience for Inventor users. PowerMill excels in complex high-speed, 3-axis, and 5-axis machining, often favored in tool & die and aerospace. FeatureCAM is known for its automation through feature recognition.

- SolidCAM is known for its seamless integration within SolidWorks and its patented iMachining technology for optimized toolpaths.

- Esprit is powerful for multi-axis, multi-turret, and multi-spindle machines, common in high-production environments or for very complex "done-in-one" parts.

Industries often have specific needs. For example, aerospace might demand CAM software with strong 5-axis simultaneous toolpaths and advanced material removal strategies for tough alloys. Medical device manufacturing needs excellent support for micro-machining and verification for extremely tight tolerances. For Alex’s robotic components, a CAM system with strong multi-axis support, excellent simulation, and collision checking would be crucial. At QuickCNCs, we select the CAM tool that best fits the specific part geometry, material, and the precision required by our clients.Conclusion

Choosing the right CAM software is vital for efficient, precise CNC machining. Understanding its role, how it generates G-code, and popular options helps you make informed decisions for your industry needs.