Have you heard the terms "Industry 4.0" and "IoT" but wonder if they’re just buzzwords? You worry that behind the marketing, your outsourced CNC parts are still being made with old methods, leaving quality and delivery times to chance. You need real results, not just fancy terms.

Smart manufacturing, driven by the Internet of Things (IoT) and Industry 4.0 principles, is transforming Chinese CNC services by making them more transparent, precise, and reliable. Connected machines provide real-time data, enabling predictive quality control, automated efficiency, and giving you a clear view into your project’s entire lifecycle. This shift means fewer errors, faster turnarounds, and better parts.

Over the past decade, I’ve walked the floors of hundreds of machine shops across China. I’ve seen the evolution from traditional, manually-driven workshops to the hyper-connected "smart factories" of today. This isn’t a distant future; it’s happening right now. At QuickCNCs, we partner with these forward-thinking suppliers because they deliver a level of quality and accountability that was impossible just a few years ago. Let’s break down what this transformation really means for your projects.

How does Industry 4.0 actually improve CNC machining quality?

Worried about inconsistent quality, where the first prototype is perfect but the tenth production part is out of spec? This variation, often due to tiny differences in machine setup or operator skill, can lead to costly failures in your final assembly. You need every single part to be identical.

Industry 4.0 improves CNC quality by creating a "digital thread" that minimizes human error and enforces consistency. Through digital twins, machines are simulated and optimized before cutting. During production, closed-loop feedback systems use sensor data to make real-time micro-adjustments, ensuring every part is machined to the exact same standard, every time.

I once had a German client, an engineer like Alex, who designed a complex hydraulic manifold with extremely tight tolerances on internal channels. In a traditional shop, the skill of the individual machinist would determine the part’s success. But we placed the job with a partner factory that used Industry 4.0 principles. They created a complete digital twin of the part and the machining process first. The simulation caught a potential tool clearance issue on the fifth axis, an error that a human might have missed. They adjusted the CAM program before a single piece of aluminum was touched. The result was a perfect first article and a flawless production run.

From Manual Setup to Digital Command

In the past, machinists would manually interpret 2D drawings and set up their machines, which introduced variables. Today, the process is driven by data.

- Digital Twin Simulation: Before production, a virtual model of the CNC machine runs the exact G-code to be used. This digital rehearsal identifies potential collisions, optimizes toolpaths for speed and surface finish, and verifies that the final part will match the 3D CAD model perfectly.

- Centralized Program Management: The exact, approved machining program is sent directly to the machine from a central server. This eliminates the risk of an operator accidentally using an outdated version of a file.

Consistency Through Closed-Loop Feedback

This is where the "smart" part truly shines. An Industry 4.0-enabled machine doesn’t just run a program blindly; it feels and reacts.

| Feature | Traditional CNC Process (Open-Loop) | Industry 4.0 CNC Process (Closed-Loop) |

|---|---|---|

| Tool Wear | Operator inspects tools manually between jobs. Risk of using a worn tool. | Sensors monitor spindle load and vibration. System flags a tool for replacement automatically. |

| Material Variation | Assumes material block is perfectly uniform. | Probing systems measure the raw material in the machine and adjust toolpaths to compensate. |

| Thermal Expansion | Machine position can drift as it heats up, affecting tolerances. | Temperature sensors on the machine frame and spindle trigger automatic position compensation. |

This closed-loop system is constantly checking and correcting, achieving a level of precision and repeat-ability that is simply not possible with manual oversight alone.

How is the Internet of Things (IoT) creating more transparent production lines?

Are you tired of sending an email and getting a vague reply like "your order is in progress"? This lack of visibility is frustrating and makes it impossible to plan your own assembly and testing schedules effectively. You feel like your project has disappeared into a black box.

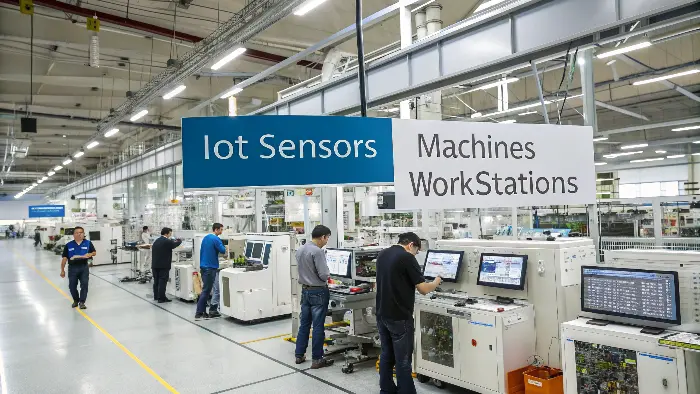

The Internet of Things (IoT) creates transparency by connecting every machine, workstation, and process on the factory floor. Sensors collect real-time data on machine status, cycle times, and quality checks. This data is fed into a dashboard, giving you a clear, minute-by-minute view of exactly where your parts are in the production flow.

We work with a client who builds medical devices, and their project timelines are incredibly strict. For years, they struggled with planning because they never had reliable status updates from their suppliers. We connected them with one of our smart factory partners. Now, they can log into a web portal and see a dashboard for their order. They see a "digital traveler" that shows their parts moving from the raw material storage, to CNC Machine #A7, to the CMM for inspection, and finally to the packaging station. This level of transparency has been a game-changer for them, allowing them to schedule their downstream activities with confidence.

The Anatomy of a Connected Factory

So what is actually being connected? It’s more than just putting a machine "online."

- Machine Sensors: These are the eyes and ears of the system. They track metrics like On/Off status, current job number, cycle time per part, spindle speed, and temperature.

- Station Scanners: At each workstation (e.g., deburring, quality inspection, anodizing), an operator scans a barcode on the job ticket. This updates the project’s status in the central system instantly.

- Central Data Hub: All this information from sensors and scanners flows into a single database. This hub is the "single source of truth" for the entire factory.

Your Window into the Factory Floor

This connected infrastructure allows for powerful client-facing tools. Instead of guessing, you get facts.

| Information Flow | Traditional Factory | IoT-Enabled Smart Factory |

|---|---|---|

| Order Status | You email a salesperson, who asks the production manager, who asks a foreman. | You log into a portal and see the real-time status: "Machining – 75/100 complete." |

| Quality Reports | You receive a PDF of the final inspection report at the end of the job. | You can see CMM inspection results for first articles and in-process checks as they happen. |

| Estimated Completion | "Maybe next Tuesday." | The system calculates the estimated completion date based on real-time production speed and remaining steps. |

This transparency builds immense trust. You are no longer just a customer; you are an informed partner in the manufacturing process.

Can automation really lower my costs without sacrificing customization?

Do you associate automation with massive, million-part assembly lines and assume it doesn’t apply to your custom, low-volume CNC orders? You might think your unique designs require the hands-on skill of a machinist, making automation an irrelevant expense. This is a common misconception.

Yes, modern "flexible automation" is specifically designed for high-mix, low-volume work and directly lowers costs on custom jobs. Instead of fixed assembly lines, it uses adaptable robotic arms for tasks like loading machines and automated systems for quality control. This reduces manual labor and allows for 24/7 operation, making even a one-off prototype cheaper to produce.

The biggest cost driver in custom CNC machining isn’t the material; it’s the skilled labor and machine time. A few years ago, I toured a facility that had just invested in a robotic cell for one of its 5-axis mills. The owner told me his goal wasn’t to produce millions of the same part. His goal was to run the machine all night long, unattended, making a different custom part every hour. The robot would unload a finished part, load a new blank, signal the machine to pull up the next G-code from the server, and then place the finished part in a CMM for automated inspection. This "lights-out manufacturing" drastically reduced the cost per part, a saving he passed on to his clients.

Flexible Automation: The Key to Custom Efficiency

It’s important to understand the difference between old and new automation.

- Hard Automation: This is what car factories use. The system is built to do one task millions of times. It is very efficient but completely inflexible.

- Flexible Automation: This uses modern robotics and smart software. A robotic arm can be quickly reprogrammed to handle parts of different shapes and sizes. It automates the repetitive tasks associated with custom work, not the entire process.

Direct Cost Savings on Your Custom Part

So how does a robot loading a machine help your specific project?

| Cost Component | Traditional Custom Machining | Flexible Automation Machining | Impact on Your Quote |

|---|---|---|---|

| Machine Setup | A skilled operator manually loads blanks and fixtures for each new job. | The robot uses standardized pallets. Setup for the next job is prepared while the current one is running. | Lower setup fees, especially for small batches. |

| Labor Cost | High, as a skilled operator is needed to tend the machine constantly. | Much lower. One operator can supervise a cell of several automated machines. | Reduced direct labor cost per hour. |

| Machine Utilization | Typically runs for one or two shifts, 8-16 hours per day. | Can run 24/7, including "lights-out" shifts, drastically increasing output. | The machine’s hourly rate can be lower because its fixed cost is spread over more operating hours. |

By automating the loading, unloading, and inspection, the most expensive components—the CNC machine and the skilled technician— become dramatically more productive. This makes advanced manufacturing accessible and affordable even for prototype orders.

How is data analytics preventing production errors before they happen?

Are you tired of projects being delayed at the last minute because a defect was only found during final inspection? This reactive approach scraps already-machined parts, wastes expensive material, and puts your entire schedule at risk. You need to catch problems before they even start.

Data analytics prevents errors by shifting from reactive to predictive quality control. By continuously analyzing data from IoT sensors—like machine vibration, temperature, and motor power—algorithms can detect subtle patterns that indicate a future failure. This allows the system to schedule maintenance or flag an issue before a single out-of-tolerance part is ever produced.

We work with an aerospace client where a single component failure could have catastrophic consequences. Their parts require extensive documentation and zero defects. One of our smart factory partners uses predictive analytics on all their machines. One morning, the system flagged a tiny, abnormal increase in the spindle motor’s power draw and vibration on a specific machine. It wasn’t enough to affect the part quality yet, but the algorithm predicted a bearing failure was likely within the next 48 operating hours. They took the machine offline for a two-hour preventative maintenance window, replacing the bearing. If they had waited, it would have failed mid-production, scrapping an expensive block of titanium and causing a multi-day delay.

From Reactive Repairs to Predictive Maintenance

This represents a fundamental shift in factory operations.

- Reactive Maintenance (The Old Way): The machine runs until something breaks. Production stops, and there are lengthy, unplanned downtimes and potentially a batch of bad parts.

- Preventive Maintenance (Better): Maintenance is scheduled at regular intervals (e.g., every 500 hours), whether it’s needed or not. This is better but can lead to unnecessary downtime and cost.

- Predictive Maintenance (The Smart Way): Maintenance is performed only when data indicates it’s actually needed. This maximizes uptime and prevents failures.

In-Process Quality Control Through Data

Beyond predicting machine failure, data analytics can also spot problems during the cutting process itself.

| Error Type | Traditional Detection Method | Predictive Analytics Detection Method |

|---|---|---|

| Tool Breakage | The operator hears a crash, or the machine alarms after the tool is already broken. | The system detects a sudden spike in torque and vibration and stops the machine before the tool catastrophically fails. |

| Incorrect Dimensions | The part is finished and then measured at the final Quality Control station. | An in-machine probe measures the feature mid-cycle. If it’s drifting, the machine automatically adjusts the tool offset for the next cut. |

| Poor Surface Finish | A quality inspector visually rejects the part after it comes out of the machine. | The system detects high-frequency vibrations during a finishing pass, indicating chatter, and flags the part for inspection immediately. |

This data-driven approach means quality is not just inspected at the end; it is actively managed and built into every step of the manufacturing process.

Conclusion

Smart manufacturing in China is not a future promise; it’s a present-day reality. It delivers the transparency, consistency, and efficiency that engineers like you demand for your most critical projects.