Are you struggling to find a material that is strong, lightweight, and safe for medical devices? The unique properties of carbon fiber make it ideal, but machining it presents major challenges. One mistake can lead to delamination, ruining an expensive component and causing project delays.

The best way to machine carbon fiber for medical devices like prosthetics and implants is through specialized CNC machining. This involves using specific PCD (polycrystalline diamond) tools, high spindle speeds, and moderate feed rates. Proper dust extraction is critical to protect the material, the machine, and the operator. For complex 3D shapes, molding techniques are often combined with final CNC finishing to achieve the required precision.

I’ve seen many engineers like you face this problem. They are excited by carbon fiber’s potential but worried about the manufacturing complexities. You need a partner who understands both the material’s properties and the precision required for medical applications. I’ve spent years working with carbon fiber, and I can tell you that success comes down to a deep understanding of the right techniques. Let’s explore these methods together so you can bring your designs to life with confidence.

Why Choose Carbon Fiber for Prosthetics?

Sticking with traditional materials like metal or plastic for prosthetics can lead to heavy, bulky, or fragile devices. This leaves users feeling uncomfortable and limited. You need a solution that offers strength and freedom without weighing the user down, but finding such a material can be difficult.

Carbon fiber is the top choice for high-performance prosthetics because of its incredible strength-to-weight ratio. It allows for designs that are both durable and extremely light, reducing fatigue for the user. Its ability to store and release energy also mimics a natural gait, greatly improving mobility and comfort.

Diving Deeper into Material Properties

When I first started machining parts for prosthetics, the focus was almost entirely on metals like titanium and aluminum. They are strong and reliable. But a client from a prosthetics company in Germany, much like Alex, came to us with a new challenge. He wanted a prosthetic foot that could withstand the impact of running while being light enough for daily use. This is where carbon fiber completely changed the game.

The key advantage is its specific stiffness and specific strength. This means it’s incredibly stiff and strong for its weight. Let’s look at a simple comparison.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Strength-to-Weight Ratio (kNm/kg) |

|---|---|---|---|

| Carbon Fiber Composite | 1.6 | 1500 | 938 |

| Titanium Alloy (Ti-6Al-4V) | 4.43 | 950 | 214 |

| Aluminum Alloy (6061-T6) | 2.7 | 310 | 115 |

| Steel (4130) | 7.85 | 670 | 85 |

As you can see, carbon fiber is in a league of its own. For an amputee, this difference is life-changing. A lighter prosthesis means less energy is needed to move, reducing muscle strain and fatigue over the day.

Another critical factor is fatigue resistance. A prosthetic limb goes through millions of stress cycles. Metals can develop micro-cracks and eventually fail. Carbon fiber composites, when designed correctly, can flex and return to their original shape countless times without degrading. This ensures a longer lifespan and, more importantly, greater safety for the user. We machine these parts to ensure there are no surface imperfections that could become stress points, which is a critical step in guaranteeing that long-term reliability.

What Other Medical Devices Use Carbon Fiber?

You might think carbon fiber is only for high-tech prosthetics or sports equipment. This narrow view can cause you to miss out on its benefits for other medical applications. Relying on traditional materials like aluminum or stainless steel can lead to compromises in performance, especially in imaging and surgical tools.

Beyond prosthetics, carbon fiber is used extensively in medical imaging equipment like X-ray and CT scanner tables. Its radiolucency means it’s virtually transparent to X-rays, allowing for clearer images. It’s also used for surgical instruments, external fixators, and components for wheelchairs, offering strength and lightness.

Expanding the Scope of Applications

I remember a project for a client developing a new surgical targeting system. They were initially using aluminum for the device’s frame, which held various instruments in place during surgery. The problem was that the aluminum frame would show up on intraoperative X-rays, creating shadows and forcing surgeons to constantly adjust their view. It was a significant roadblock.

We suggested remaking the frame from a carbon fiber composite. The transition was a success. The new carbon fiber frame was just as strong and stiff, but it was radiolucent. This property is a game-changer in medical imaging.

Radiolucency in Medical Imaging

Materials like metal absorb or block X-rays, which is why our bones (which contain calcium, a dense element) show up so clearly. However, when you’re trying to view soft tissues or place a medical device accurately, you don’t want the equipment itself getting in the way. Carbon fiber is composed of low-atomic-number atoms (mostly carbon), so X-rays pass right through it. This results in cleaner, artifact-free medical images, allowing doctors to perform procedures with greater accuracy. This is why you see it in:

- CT and MRI Tables: The patient lies on a carbon fiber couch that is strong enough to support them but won’t interfere with the scan.

- Mammography Plates: The plates that position the breast tissue are made of carbon fiber for better image quality.

Surgical Instruments and External Fixators

Another key area is surgical instrumentation. For long procedures, a surgeon’s fatigue can become a factor. Lightweight carbon fiber instruments reduce strain on the surgeon’s hands and wrists. They are also non-magnetic, which is crucial for use in environments with Magnetic Resonance Imaging (MRI).

For external fixators—the rigid frames used to hold broken bones in place—carbon fiber offers the perfect blend of properties. It provides the necessary strength to stabilize the fracture, but its light weight makes it far more comfortable for the patient than a heavy steel frame. Machining the connection points and adjustment mechanisms on these fixators requires high precision to ensure the bones heal correctly.

Is Carbon Fiber Safe and Effective for Medical Implants?

Proposing an implant made from a non-traditional material can make clients nervous. They worry about the body rejecting the material or long-term breakdown inside the body. Sticking with proven metals like titanium seems safer, but it limits innovation and can lead to issues like stress shielding.

Yes, specific types of carbon fiber composites, like Carbon Fiber Reinforced PEEK (CFR-PEEK), are both safe and highly effective for medical implants. They are biocompatible, meaning they don’t cause adverse reactions in the body. Their stiffness can be matched to bone, which promotes better healing and reduces stress shielding.

Biocompatibility and Mechanical Synergy

The question of safety is the most important one when we talk about implants. You can’t just put any material inside the human body. For years, our go-to material for implants that required CNC machining was medical-grade titanium (Ti-6Al-4V ELI). It’s strong and has excellent biocompatibility. However, it has one major drawback: it is much stiffer than human bone.

This stiffness mismatch causes a problem called stress shielding. Bone needs mechanical stress to stay strong and healthy. When a stiff titanium implant is placed next to it, the implant carries most of the load. The surrounding bone is "shielded" from stress and can begin to weaken and lose density over time. This can lead to the implant loosening or the bone becoming more prone to fracture.

This is where carbon fiber composites, particularly CFR-PEEK, offer a revolutionary advantage. PEEK (Polyetheretherketone) is a high-performance polymer already widely used in spinal and orthopedic implants due to its biocompatibility and toughness. By reinforcing it with carbon fibers, we can create a composite material with tailored properties.

| Property | Human Cortical Bone | Titanium (Ti-6Al-4V) | CFR-PEEK |

|---|---|---|---|

| Elastic Modulus (GPa) | 12-18 | 110 | 12-18 |

| Biocompatibility | Excellent | Excellent | Excellent |

| Radiolucency | Opaque | Opaque | Radiolucent |

As the table shows, the stiffness (Elastic Modulus) of CFR-PEEK can be engineered to closely match that of human bone. This means the implant and the bone share loads more naturally. The bone receives the stress it needs to remodel and stay healthy, leading to better long-term outcomes for the patient. We worked on a project for spinal fusion cages made from CFR-PEEK. The designs were complex, with intricate porous structures to encourage bone ingrowth. The ability to precisely CNC machine these features while maintaining the material’s integrity was essential for the product’s success. The radiolucency was also a bonus, allowing surgeons to clearly assess the fusion site on post-operative X-rays.

What are the Key Machining Techniques for Carbon Fiber Medical Parts?

You have a perfect design for a carbon fiber medical part, but getting it made is a nightmare. Standard machine shops might treat it like metal, causing delamination, fiber pull-out, and inaccurate features. This wastes expensive material and puts your project weeks behind schedule.

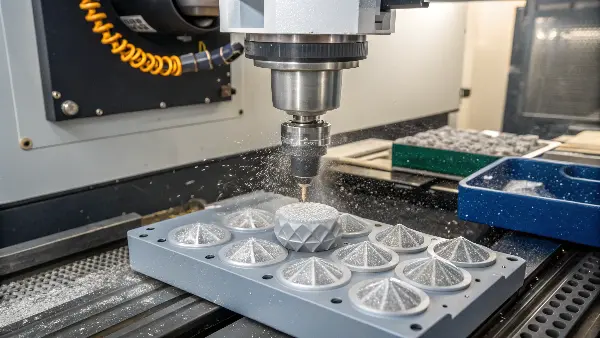

Successful machining of carbon fiber medical parts relies on a combination of molding and precision CNC machining. First, a near-net shape is created using techniques like compression molding. Then, CNC milling with PCD tools is used for critical features like holes, slots, and precise contours, ensuring tight tolerances (±0.01mm) are met.

A Two-Stage Process: Molding and Machining

Machining carbon fiber isn’t like cutting a block of aluminum. Carbon fiber composites are anisotropic, meaning their properties are directional. They are also highly abrasive. Using the wrong approach will destroy both the part and your tools. I learned this the hard way early in my career when a standard high-speed steel (HSS) end mill became completely dull after just a few centimeters of cutting.

The most effective strategy is a two-stage process.

Stage 1: Creating the Blank (Molding)

You rarely start with a solid block of carbon fiber. Instead, the part’s basic shape is formed first.

- Compression Molding: Layers of pre-impregnated carbon fiber fabric (pre-preg) are placed into a heated mold. The mold is closed under high pressure, compacting the layers and curing the resin. This is great for parts with complex curvatures, like the socket of a prosthetic limb.

- Autoclave Curing: For the highest quality and lowest porosity, parts are cured in an autoclave. This is essentially a high-pressure oven. The high pressure ensures all layers are perfectly consolidated. This method is used for critical aerospace and high-performance medical components.

Stage 2: Precision CNC Machining

Once we have the molded "blank," we move to the CNC machine for the finishing touches. This is where we create the features that demand high accuracy. An engineer like Alex would be very interested in this part of the process.

Critical Considerations for CNC Machining Carbon Fiber:

- Tooling: Standard HSS or carbide tools will wear out almost instantly. Polycrystalline Diamond (PCD) tools are the industry standard. The diamond cutting edges are extremely hard and can withstand the abrasive nature of the carbon fibers. We use specialized drills with unique geometries to prevent delamination when entering and exiting the material.

- Cutting Parameters: High spindle speeds (RPM) and moderate feed rates work best. Too slow, and you generate excessive heat, which can damage the resin matrix. Too fast a feed rate, and you risk ripping the fibers instead of shearing them cleanly.

- Dust Control: This is a non-negotiable safety requirement. Carbon fiber dust is electrically conductive and a respiratory hazard. All our CNC machines working on carbon fiber are equipped with high-volume vacuum systems that capture dust directly at the cutting tool. This protects our equipment and, more importantly, our technicians.

- Workholding: The part must be held securely without crushing it. We often use custom vacuum fixtures or low-clamping-force jigs that support the part across a large surface area.

For a prosthetic component, we might receive a molded carbon fiber socket. Our task would be to CNC machine the mounting holes and trim the edges to a precise profile. We would use a PCD end mill for the profiling and a specialized "dagger" or "brad-point" drill for the holes to achieve a clean cut without any splitting or fraying of the fibers.

Conclusion

In summary, carbon fiber’s unique properties make it an exceptional material for prosthetics and implants. Success hinges on mastering specialized molding and precision CNC machining techniques for optimal results.