Struggling to pick the perfect aluminum alloy from a sea of options? Making the wrong choice can lead to part failure, budget overruns, and project delays. I’m here to help you navigate the choices and select the ideal material for your specific needs with confidence.

The best way to choose an aluminum alloy is to match its specific properties to your application’s demands. Start by considering the most common series: 6000 series for general-purpose use and good machinability, 7000 series for high-strength applications like aerospace, and 5000 series for excellent corrosion resistance, especially in marine environments. Balancing performance, cost, and manufacturability is key to making the right decision.

Over my years in manufacturing, I’ve seen many talented engineers get stuck on material selection. It’s understandable. The datasheets are full of numbers, and the names like "6061-T6" or "7075-T651" can seem cryptic. But getting this right is the foundation of a successful part. A great design made from the wrong material is still a failed part. Let’s break this down together, so you can move forward with your project.

What Are the Most Common Aluminum Alloy Series for CNC Machining?

You have a design ready, but the material dropdown list is overwhelming. Which series is for what? Choosing incorrectly means you might pay for strength you don’t need or get a part that corrodes unexpectedly. Let’s clear up the confusion around these numbers.

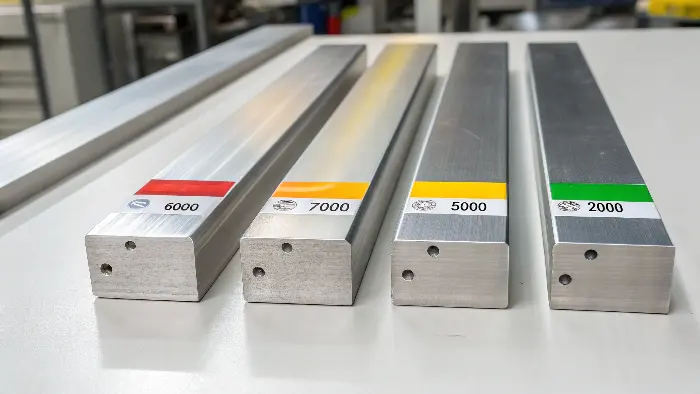

The most common aluminum alloys for CNC machining fall into four main series. The 6000 series (like 6061) is the workhorse, great for general use. The 7000 series (like 7075) is for high-stress parts. The 5000 series (like 5052) is for parts that need to resist corrosion. And the 2000 series (like 2024) offers high strength but with lower corrosion resistance.

When I first started in a CNC shop, the series numbers were just codes to me. But I quickly learned they tell a story about the metal’s main ingredients and what it’s good at. The first digit is the most important clue. It tells you the principal alloying element, which defines the material’s core characteristics. Think of it as a family name.

For an engineer like Alex, who works on high-precision robotics, understanding these families is crucial. You might use one series for a structural arm component and a completely different one for the outer housing.

A Quick Guide to Aluminum Families

Here’s a simple breakdown of the series we see most often in machining projects:

| Alloy Series | Primary Alloying Element(s) | Key Characteristics | Common Applications |

|---|---|---|---|

| 2xxx | Copper (Cu) | High strength, good fatigue resistance, heat-treatable. | Aerospace structures, aircraft fittings. |

| 5xxx | Magnesium (Mg) | Excellent corrosion resistance, good weldability. | Marine parts, tanks, pressure vessels. |

| 6xxx | Magnesium (Mg) & Silicon (Si) | Good machinability, good strength, weldable. | General structural parts, electronics. |

| 7xxx | Zinc (Zn) | Highest strength, heat-treatable, good hardness. | High-stress aerospace parts, molds. |

I remember a client who was developing a new camera drone. They initially specified 7075 aluminum for the entire frame, thinking "strongest is best." But after we talked, we realized only the motor mounts needed that extreme strength. For the main body, we switched to 6061. This saved them nearly 30% on material and machining costs without sacrificing performance where it mattered. This is why understanding the series is so important. It’s about using the right tool for the job.

How Do You Compare Key Properties Like Strength, Corrosion Resistance, and Machinability?

You know the different alloy families, but now you have to make a trade-off. The strongest alloy might not have the corrosion resistance you need. The easiest-to-machine alloy might not be strong enough. How do you balance these competing factors to avoid a costly mistake?

To compare alloys, focus on their key performance indicators. Use a simple rating system. For example, 7075 offers the highest strength but has average corrosion resistance. 5052 has excellent corrosion resistance but moderate strength. 6061 provides a great all-around balance of good strength, corrosion resistance, and machinability, making it a popular default choice for many applications. Always check the material datasheet for specific values.

Choosing an alloy is always an exercise in balancing priorities. You can’t have it all. The key is to identify what is a "must-have" versus a "nice-to-have" for your specific part. I always ask my clients to rank their priorities. Is this part holding a heavy load? Is it exposed to saltwater? Does it need a perfect, mirror-like finish? The answers to these questions point us to the right material.

Let’s look at the three most critical properties for most machined parts.

Strength-to-Weight Ratio

This is often the number one reason engineers choose aluminum. For applications in robotics or aerospace, you need the part to be as strong as possible while being as light as possible. 7075 is the champion here. It has a strength comparable to some steels but at a fraction of the weight. But this strength comes with challenges, as it’s harder to machine and weld.

Corrosion Resistance

If your part will be used outdoors, in a humid environment, or near the ocean, this is your most important property. The 5000 series alloys, like 5052 and 5083, are the winners here. They don’t have the high strength of the 7000 series, but they will last much longer in corrosive settings. 6061 also has good corrosion resistance, making it a safe choice for many products. The 2000 series, with its high copper content, is generally poor in this area and often needs a protective coating.

Machinability

For us in the machine shop, this is a huge factor. "Machinability" refers to how easily and quickly we can cut the material. Good machinability means faster cycle times, less tool wear, and a better surface finish. This all translates to a lower cost for you. 6061 is famous for its excellent machinability. 7075, being much harder, is more difficult to machine. It creates smaller chips and causes more wear on our cutting tools, which increases the machining time and cost.

Which Aluminum Alloys Are Best for Specific Applications?

You understand the properties, but how does that translate to the real world? Seeing a list of numbers is one thing, but knowing that a specific alloy is trusted by an entire industry for a certain application gives you much more confidence in your choice.

Match the alloy to the industry standard. For aerospace and high-performance robotics, use 7075 for its strength. For consumer electronics enclosures, use 6063 for its excellent surface finish. For marine applications, use 5052 or 5083 for their corrosion resistance. For general-purpose prototypes and structural parts, 6061 is almost always a safe and cost-effective starting point.

Over the years, I’ve machined parts for almost every industry you can think of. Each one has its go-to materials, chosen after decades of testing and real-world experience. While you can always innovate, starting with the industry standard is a smart way to reduce risk. It gives you a proven baseline to work from.

Here are some common examples I see every day in my shop.

Aerospace & Defense

This industry demands the highest performance, period. Strength and low weight are everything.

- 7075: The king of high-strength aluminum. Used for critical structural components like aircraft wing spars and frames. Its fatigue resistance is also excellent, which is vital for parts that undergo repeated stress cycles.

- 2024: Another popular choice for aerospace. It has slightly lower strength than 7075 but better fatigue resistance in some cases, making it ideal for fuselage and wing skins where tension and stress are constant.

Automotive & Robotics

Here, the goal is a balance of strength, weight, and cost.

- 6061: A true all-rounder. We use it for everything from chassis components and suspension parts to robotic arms and fixtures. It’s strong enough for many structural applications but remains affordable and easy to machine. For an engineer like Alex, this is often the default choice for prototyping new robotic systems.

Consumer Electronics

In this market, appearance is just as important as performance.

- 6063: Often called "architectural aluminum." Its main advantage is its ability to be extruded into complex shapes and its excellent surface finish, which is perfect for anodizing. You’ll find it in laptop cases, smartphone bodies, and heat sinks. It’s not as strong as 6061, but it doesn’t need to be.

What Are the Cost Implications of Different Aluminum Alloys?

You’ve found the perfect alloy with the ideal properties for your application. But then you see the price quote and it’s double what you expected. Why does one aluminum alloy cost so much more than another? Understanding the cost drivers is key to designing a part that is both functional and manufacturable within your budget.

The cost of an aluminum alloy is driven by three main factors: the raw material price, its machinability, and its availability. Common alloys like 6061 are inexpensive and easy to machine. High-strength alloys like 7075 have more expensive alloying elements and are harder to machine, which increases both material and labor costs, making them significantly more expensive.

I often have conversations with clients about cost. It’s a critical part of any project. An engineer might specify a high-performance material, but if it makes the final product too expensive, the project won’t succeed. The "best" material is one that meets the technical requirements at a price the market can support.

Let’s break down the factors that influence the final price you pay for a machined part.

Raw Material Cost

This is the baseline price of the metal itself. The cost is influenced by the alloying elements. Zinc (for 7000 series) and copper (for 2000 series) are more expensive than the silicon and magnesium used in the 6000 series. This is why a block of 7075 aluminum costs more than a same-sized block of 6061 before we even turn on a machine.

Machinability Costs

This is a hidden cost that many engineers don’t consider. As I mentioned before, a harder material like 7075 wears down our cutting tools faster and requires slower cutting speeds. This means the machine runs for longer to produce your part. More machine time and more tooling costs directly translate to a higher price for you. An easy-to-machine material like 6061 allows for faster production and lower labor costs.

Availability and Form

Common alloys like 6061 are produced in huge quantities and are readily available in many forms (plates, bars, sheets). Less common alloys or specific tempers might need to be special-ordered, which adds cost and lead time.

Here is a simple cost comparison:

| Alloy | Relative Material Cost | Relative Machining Cost | Overall Cost Index |

|---|---|---|---|

| 6061 | Low | Low | $ |

| 5052 | Low-Medium | Low | $ – $$ |

| 7075 | High | High | $$$ – $$$$ |

My advice is always this: don’t over-specify. Use 6061 as your default unless you have a clear, justifiable reason to use something more expensive.

Conclusion

Choosing the right aluminum alloy is a balancing act. You need to weigh performance, application requirements, and cost. By understanding the main alloy series and their key properties, you can make an informed decision that ensures your project is a success from the start.