Aerospace parts demand extreme precision. Fixturing errors cause costly rework and delays. Effective fixturing solutions are essential to ensure accuracy, efficiency, and meet those critical tolerances.

Mastering CNC fixturing for aerospace involves a deep understanding of part geometry, material properties, and machine capabilities. Selecting or designing the right fixtures—like modular, vacuum, or custom systems—is key to achieving tight tolerances and high-quality finishes on demanding components.

Getting the fixturing right from the start is absolutely crucial in aerospace manufacturing. I’ve seen projects go sideways because of a poorly thought-out workholding strategy. It’s not just about holding the part; it’s about holding it securely, repeatably, and without causing distortion. For engineers like you, Alex, who are dealing with high-tolerance parts, understanding these fixturing nuances can make all the difference. Let’s explore how specific solutions can help you avoid common pitfalls and ensure your designs are manufactured to perfection. This knowledge will empower you to make better decisions when outsourcing CNC machining work.

What Makes Fixturing Aerospace Parts So Uniquely Challenging?

Complex shapes and tight tolerances make aerospace fixturing a real headache. Even small mistakes can lead to scrapped parts and significant delays. Understanding these specific challenges is the very first step.

Aerospace parts often feature thin walls, intricate contours, and are made from difficult-to-machine materials like titanium or Inconel. These factors demand fixtures that provide exceptionally rigid support without deforming the workpiece, ensuring dimensional accuracy throughout the machining process.

When I first started in a CNC shop, I quickly learned that aerospace components are in a league of their own. It’s not just about the complex geometries; the materials themselves present huge hurdles. For instance, many aerospace alloys, like heat-treated aluminum or titanium, have high strength-to-weight ratios but can be prone to warping or internal stresses if not fixtured correctly. Thin-walled structures, common in aerospace for weight reduction, are particularly susceptible to distortion from clamping forces or even the cutting forces themselves. I recall a project involving a thin-walled housing where initial attempts with standard clamps led to out-of-tolerance parts. We had to rethink our entire fixturing approach.

Consider these common challenges:

- Material Properties:

- Titanium/Inconel: High strength, poor thermal conductivity (generates lots of heat), work hardening.

- High-Strength Aluminum: Can be gummy or distort easily if not supported well.

- Part Geometry:

- Thin Walls: Prone to vibration and deflection.

- Complex Contours: Difficult to grip securely and consistently.

- Large Sizes: Can be unwieldy and require substantial support.

- Tolerance Requirements: Aerospace often demands tolerances down to ±0.01mm or even tighter, leaving no room for fixturing error.

- Residual Stresses: Machining can release internal stresses in the material, causing parts to warp after being removed from the fixture if not properly managed during fixturing and machining.

Addressing these requires a fixturing solution that offers robust support, minimizes vibration, and applies clamping forces strategically to avoid any deformation.Can Modular Fixturing Systems Adapt to Diverse Aerospace Needs?

You might be wondering if there’s a versatile fixturing option for various aerospace parts. Custom fixtures for every single component can get very expensive, fast. Modular systems offer a highly adaptable and cost-effective solution.

Yes, modular fixturing systems offer excellent adaptability for a wide range of aerospace components. Their reconfigurable nature allows for quick setup changes, significantly reducing lead times and costs, especially for prototyping and small to medium batch production.

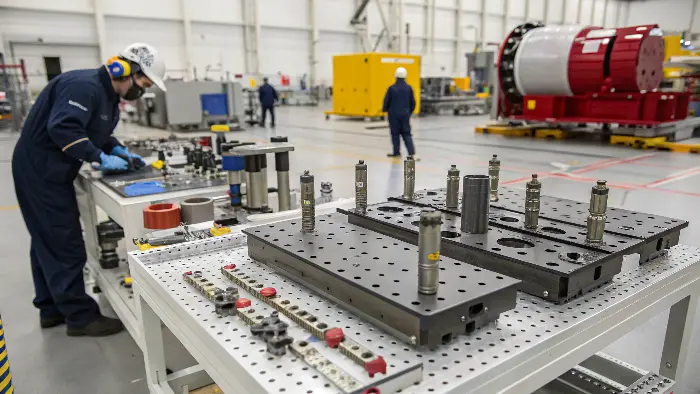

I’ve seen modular fixturing systems save the day on many occasions, especially when we’re working on prototypes or small production runs for clients like your robotics company, Alex. The beauty of these systems lies in their Lego-like construction. You have base plates with a grid of holes, and a wide array of standardized components like clamps, locators, risers, and supports that can be assembled in countless configurations. This means you can quickly build a fixture for one part, and then reconfigure it for a completely different part with minimal downtime. This flexibility is invaluable when you’re iterating through designs or have a diverse mix of low-volume parts. For aerospace, this often means quicker turnarounds for first articles and test pieces.

Here’s a breakdown of why they’re useful:Feature Benefit for Aerospace Consideration Reconfigurability Fast setup for prototypes and small batches. May require skilled setup for complex geometries. Cost-Effectiveness Lower initial investment than multiple custom fixtures. Component costs can add up for extensive systems. Standardization Consistent locating and clamping. May not offer the ultimate rigidity of a custom fixture. Reduced Lead Time Quickly build fixtures without design/fabrication delay. Not ideal for very high-volume, repetitive tasks. While modular systems are fantastic for versatility, it’s important to ensure the assembled fixture provides enough rigidity for the specific machining operations and materials involved. For high-force machining or extremely tight tolerance work on challenging materials, you still might need to look at other options, or at least be very meticulous in your modular setup.

When is Vacuum Fixturing the Optimal Choice for Aerospace Machining?

Are you machining large, flat, or particularly delicate aerospace parts? Traditional mechanical clamping methods can sometimes distort these types of components. Vacuum fixturing offers a non-invasive, yet incredibly secure, holding solution.

Vacuum fixturing is ideal for aerospace components like thin sheets, skins, large flat panels, or non-magnetic materials. It provides uniform clamping pressure across a surface without introducing mechanical stress, perfect for maintaining flatness and preventing part distortion during machining.

I remember a specific project where we were machining large, thin aluminum panels for an aircraft fuselage. Any attempt to clamp them mechanically resulted in slight bowing or marking on the surface. This is where vacuum fixturing really shone. By using a vacuum chuck, we could hold the entire panel securely against a flat reference surface with evenly distributed pressure. This completely eliminated distortion and allowed us to machine features with excellent precision and achieve a superior surface finish. For aerospace applications, especially with thin skins, composite layups, or honeycomb structures, vacuum workholding is often the go-to method. It’s also brilliant for parts where you need access to five full sides for machining without re-clamping.

Here’s how it generally works and its key advantages: - Principle: A vacuum pump creates a low-pressure area between the workpiece and a fixture plate (chuck) that has channels or porous areas. Atmospheric pressure then pushes the workpiece firmly against the fixture.

- Types of Vacuum Fixtures:

- Vacuum Chucks: Flat plates with grooves or holes connected to a vacuum source.

- Vacuum Pods: Individual suction cups that can be positioned to support complex shapes.

- Porous Ceramic or Graphite Chucks: Offer distributed holding over the entire surface.

Benefits for Aerospace Components:

- Distortion-Free Clamping: No mechanical stress points, crucial for thin or delicate parts.

- Full Surface Access: Often allows machining of five sides without obstruction from clamps.

- Uniform Holding Pressure: Ensures stability and consistent machining results.

- Suitable for Non-Magnetic Materials: Works perfectly with aluminum, composites, and plastics.

However, Alex, you should also be aware of some limitations. The part surface in contact with the vacuum fixture needs to be relatively smooth and flat to achieve a good seal. Also, for very aggressive roughing operations with high cutting forces, the holding power might be a concern if the surface area for vacuum is limited.Why Opt for Custom-Designed Fixtures in High-Stakes Aerospace Production?

What about situations involving high-volume production or extremely complex aerospace parts where standard or modular solutions just don’t cut it? In these scenarios, investing in custom-designed fixtures provides dedicated, highly optimized solutions.

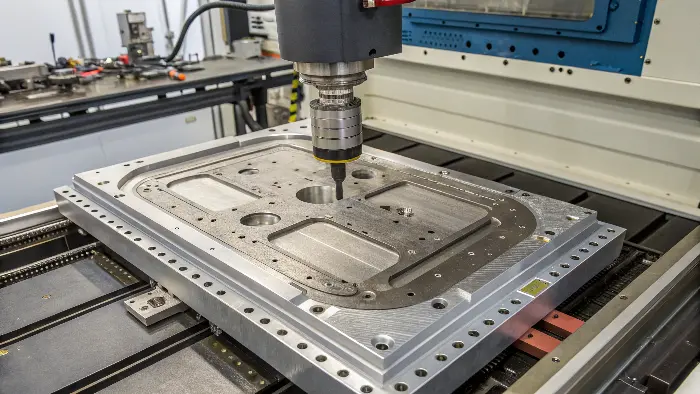

Custom-designed fixtures are chosen for high-volume aerospace production or parts with unique, intricate geometries where standard solutions fall short. They are engineered to maximize rigidity, repeatability, and efficiency for specific machining operations, ensuring consistent quality.

When a client needs tens of thousands of an identical, complex aerospace component, or when a part has such unusual features that no off-the-shelf solution can securely or accurately hold it, then we always move towards custom fixturing. I’ve overseen the design and implementation of many such fixtures. The initial investment in design and fabrication is higher, no doubt. But the long-term benefits in terms of reduced cycle times, lower scrap rates, and improved process reliability for high-volume runs almost always justify the cost. A custom fixture is engineered precisely for one part or a family of very similar parts. It considers every critical feature, every locating surface, and every clamping point to ensure the part is held in the most stable and repeatable way possible. For instance, for a complex turbine blade, a custom fixture might perfectly cradle its organic shape while providing access for multi-axis machining.

Key considerations when opting for custom fixtures: - Production Volume: High-volume makes the per-part cost of the fixture negligible.

- Part Complexity: Unique geometries or very tight, interrelated tolerances often demand custom solutions.

- Process Optimization: Can be designed to facilitate quick part loading/unloading, automated clamping, or integrated probing.

- Material & Machining Forces: Built to withstand specific cutting forces and manage chip evacuation effectively for the given material.

- Repeatability: Designed to locate the part in the exact same position every single time, crucial for lights-out manufacturing or robotic tending.

Designing a custom fixture is a detailed engineering task. We consider factors like: - Locating Strategy: Using the 3-2-1 principle or more advanced datuming schemes.

- Clamping Forces: Sufficient to hold the part but not distort it. Hydraulic or pneumatic clamping can be integrated.

- Material of the Fixture: Chosen for durability, stability, and sometimes to match the thermal expansion of the workpiece.

- Chip and Coolant Management: Ensuring clear pathways for chips and coolant to prevent build-up.

For you, Alex, if you’re designing a component that will go into mass production or has exceptionally demanding features, discussing custom fixturing with your manufacturing partner early in the design phase can be incredibly beneficial.Conclusion

Mastering CNC fixturing is vital for aerospace success. Choosing the right modular, vacuum, or custom solution ensures precision, efficiency, and quality for even the most demanding components.