Struggling with high costs on your carbon fiber parts? The material’s abrasive nature and complex handling can quickly inflate your budget. You need a strategy to get precision parts without overspending.

To optimize carbon fiber machining costs, focus on four key areas. First, choose the right material grade for your application, not just the most expensive. Second, simplify your design for manufacturability (DFM). Third, plan for smart tooling strategies. Finally, partner with a supplier experienced in handling composite materials.

I’ve seen many projects go over budget because of a few common oversights. Carbon fiber isn’t like machining aluminum or steel; it requires a unique approach. Let’s break down the exact steps you can take to control these costs and ensure your project succeeds. It all starts with the material itself.

How Does Material Selection Impact Your Total Cost?

Worried that you’re overpaying for carbon fiber sheets? Choosing a spec that’s too high for your needs adds unnecessary expense from the start. You need to balance performance with budget to make your project viable.

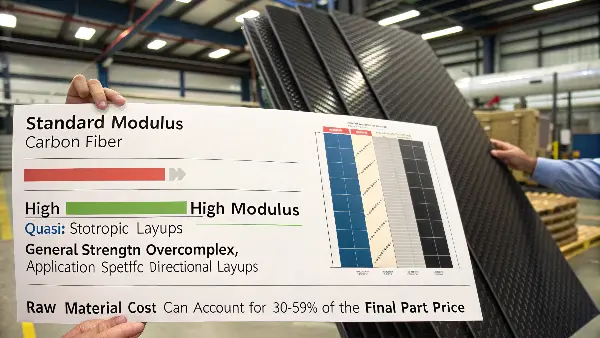

Material choice directly controls your baseline cost. Standard modulus carbon fiber is much cheaper than high or ultra-high modulus variants. Also, consider quasi-isotropic layups for general strength instead of complex, application-specific directional layups unless absolutely necessary. Raw material cost can be 30-50% of the final part price.

Your material selection is the foundation of your project’s cost. Making the right choice here can save you a significant amount before a single tool touches the part. I remember a client from a robotics startup who initially specified a high-modulus carbon fiber for a simple robotic arm casing. The material was impressive, but it was overkill for a component that mostly needed stiffness and durability, not aerospace-grade performance. By switching to a standard modulus, quasi-isotropic laminate sheet, we met all their functional requirements and cut their raw material costs by nearly 40%. The biggest savings often come from practical, not theoretical, decisions. It’s about matching the material to the real-world application.

Understanding Modulus vs. Cost

The stiffness of carbon fiber, its modulus, is a primary cost driver. You need to select a grade that makes sense for your needs. Unnecessary stiffness means unnecessary cost.

| Fiber Type | Relative Stiffness | Relative Cost | Best Use Case |

|---|---|---|---|

| Standard Modulus | 1x | 1x | Drones, robotics, automotive panels, general industrial |

| Intermediate Modulus | 1.25x | 2x – 3x | High-performance sporting goods, performance robotics |

| High Modulus | 1.5x+ | 4x – 10x+ | Aerospace, satellites, F1 components, scientific tools |

Choosing the Right Weave

The weave pattern also affects both price and how the material behaves during machining. Plain and twill are the most common. A 2×2 twill weave is often a great default choice. It’s aesthetically pleasing, drapes well over simple curves, and is readily available, making it cost-effective. A plain weave is slightly more stable but can be harder to machine without fraying. Unless you have specific structural needs for a unidirectional (UD) or satin weave, sticking to standard twill is a safe and economical bet.

Can Design Simplification Significantly Reduce Machining Time?

Are complex features in your design driving up machine hours and tool wear? Every intricate curve and tight internal corner adds time and risk. You need a design that is easy to manufacture.

Yes, absolutely. Simplifying your design is the most effective way to cut machining costs. Avoid tight internal radii by using at least a 3mm radius. Consolidate features, reduce the number of setups required, and stick to 2.5D features instead of complex 3D contours wherever possible. These changes drastically reduce machine time.

Design for Manufacturability (DFM) is not just a buzzword; it’s your most powerful tool for cost reduction. A few small design tweaks can make a huge difference. For example, a German client developing components for a medical device sent me a design with very sharp, 0.5mm internal corners. While achievable, it required extremely small, fragile tools, slow cutting speeds, and multiple finishing passes. I suggested increasing the internal radii to a more standard 3mm. This simple change allowed us to use a more robust

6mm diameter cutter, increasing the cutting speed by 400% and reducing the risk of delamination at the corners. The client agreed the change had no functional impact, and it saved them over 20% on the final part cost.

Key DFM Rules for Carbon Fiber

Following a few simple DFM principles will streamline your production process and save you money. Always think about how the part will be held and cut.

- Generous Internal Radii: This is the most important rule. Tight corners require small tools, which are slow and break easily. A radius of 3mm or more is ideal.

- Avoid Deep Pockets: Machining deep pockets in carbon fiber creates a lot of dust and causes significant tool wear. If possible, design parts that can be machined from both sides or built from thinner, laminated sheets.

- Standard Hole Sizes: Stick to standard drill bit sizes. Custom hole sizes require custom tooling or interpolation with an endmill, both of which add time and cost.

- Part Thickness: Consider the material’s standard sheet thickness when designing your part. Designing a part that is 3.1mm thick when standard sheets are 3.0mm means the entire surface must be machined down, creating waste and adding hours of machine time. Design around standard thicknesses like 1.0mm, 1.5mm, 2.0mm, 3.0mm, etc.

What’s the Best Way to Manage Tooling and Tool Wear?

Is your project budget getting eaten up by tool replacement costs? Carbon fiber is extremely abrasive and can destroy standard cutting tools in minutes. You need a an intelligent strategy for tooling.

To manage tool wear, use specialized cutting tools designed for composites. Diamond-coated (CVD or PCD) tools are the best choice. They last much longer than standard carbide tools. Also, use optimized cutting speeds and feeds, along with effective dust extraction, to reduce heat and abrasion, further extending tool life.

Tooling is a hidden cost that can surprise many engineers. Carbon fiber acts like sandpaper on cutting tools. I worked on a large-volume project for an automotive client making interior trim pieces. Initially, they budgeted based on machining aluminum. They didn’t account for the fact that a standard carbide endmill would be completely worn out after cutting just a few parts. The tooling budget was exhausted almost immediately. We stopped production and reconfigured the process. We switched to polycrystalline diamond (PCD) tipped router bits. Although the initial cost of one PCD tool was 20 times that of a carbide tool, it lasted for hundreds of parts. This single change stabilized the production cost and actually lowered the cost-per-part significantly over the full run.

Choosing the Right Tooling

Selecting the correct cutter geometry and coating is critical. It’s not just about the material of the tool, but also its shape.

| Tool Type | Description | Ideal For |

|---|---|---|

| Diamond-Coated Endmills | Carbide tools coated with a thin layer of chemical vapor deposition (CVD) diamond. | General purpose milling, slotting, and profiling. A good balance of cost and performance. |

| PCD-Tipped Tools | Tools with brazed-on tips of polycrystalline diamond. | High-volume production, straight-line cutting, and trimming. Highest cost but longest life. |

| Compression Routers | Have both up-cut and down-cut flutes. | Cutting through the full thickness of a sheet. Pushes fibers inward from top and bottom to prevent fraying. |

| Brad Point Drills | Drills with a central point and two cutting spurs. | Creating clean, delamination-free holes. The spurs score the surface before the main cutting edge removes material. |

Coolant and Dust Extraction

Unlike metals, flood coolant is generally not used for carbon fiber because the composite material can absorb the liquid, and the slurry it creates is difficult to manage. Instead, a high-power vacuum or dust extraction system is essential. It removes the abrasive dust, which reduces tool wear, keeps the part cool, and is critical for operator health and safety. The fine carbon dust is conductive and can short out electronics if not properly controlled.

How Does Choosing the Right Machining Partner Lower Your risk and Expense?

Are you worried that a low-cost supplier will deliver bad parts, causing delays and rework? Choosing a partner based on price alone often leads to higher total costs. You need a supplier who understands the nuances of carbon fiber.

A good machining partner saves you money by preventing mistakes. They offer DFM feedback, use the correct tooling and techniques, and have quality control systems designed for composites. This avoids costly scrap, rework, and project delays. Their experience is a direct investment in your project’s success and lower total cost.

Choosing your machining partner is probably the most critical cost optimization strategy of all. It’s not about finding the cheapest hourly rate; it’s about finding the lowest total cost of a successful project. I had an experience with an engineer from an American drone company. He had previously outsourced a simple carbon fiber motor mount to a general-purpose machine shop. He received parts with frayed edges, delamination around the holes, and incorrect dimensions. The parts were unusable. He lost time and money. When he came to us, the first thing we did was provide DFM feedback on his design to make it easier to machine cleanly. We then used the correct compression routers and programming techniques. The final parts were perfect, and despite our quote being slightly higher, he ultimately saved money by getting it right the first time.

What to Look for in a Supplier

When evaluating a potential partner for your carbon fiber project, ask these specific questions. Their answers will tell you a lot about their expertise.

-

"What type of tooling do you use for carbon fiber?"

- Good Answer: "We use diamond-coated or PCD tools, often with compression or burr-style geometries, depending on the feature. We match the tool to the specific layup and thickness."

- Bad Answer: "We use our standard carbide endmills."

-

"How do you control dust?"

- Good Answer: "We use a high-CFM dust collection system right at the cutter, and our machines are enclosed to contain any residual dust."

- Bad Answer: "We just vacuum it up afterwards."

-

"How do you prevent delamination and fraying?"

- Good Answer: "We use sharp, specialized tools, climb milling where appropriate, backed entry/exit points, and optimized feed rates. For critical holes, we use peck drilling cycles with brad point drills."

- Bad Answer: "It’s just part of working with carbon fiber."

-

"Can you show me examples of similar carbon fiber parts you’ve made?"

- A truly experienced supplier will have a portfolio of complex composite parts they can share. Look at the edge quality and complexity of the features.

Conclusion

To cut carbon fiber machining costs, focus on smart design, proper material selection, advanced tooling, and choosing an expert partner. These steps ensure precision and prevent expensive errors.