Are you struggling to find a reliable CNC machining partner? The process of vetting suppliers, managing quotes, and ensuring quality can be slow and frustrating, delaying your product development timeline. What if there was a more streamlined way to get high-quality custom parts, delivered right when you need them?

Custom online CNC machining services work by providing a digital platform where you upload your CAD files, specify materials, finishes, and quantities, and receive an instant or rapid quote. You then place an order, and the platform manages the entire production process with vetted suppliers, including quality control and logistics. This model simplifies procurement, reduces lead times, and offers access to a global network of manufacturing capabilities, all from your desktop.

I’ve spent over a decade in this industry, starting on the shop floor and later helping hundreds of overseas clients like you. I’ve seen firsthand how the right manufacturing partner can make or break a project. The shift to online platforms has changed the game, but it also brings new questions. How do you choose the right one? How can you trust a supplier you’ve never met?

This guide is meant to answer those questions. I want to walk you through the entire process, from getting a quote to receiving your finished parts. My goal is to give you the confidence to use these powerful services to bring your designs to life, faster and more efficiently. Let’s dive into what makes these services tick and how you can make them work for you.

How Do You Choose the Right Online CNC Service Provider?

Finding the right partner online feels like a huge risk. You see dozens of websites all promising precision, speed, and low costs, but how do you know who will actually deliver? Choosing the wrong one can lead to missed deadlines, parts that don’t meet spec, and a lot of wasted money.

To choose the right online CNC service, evaluate their technical capabilities, quality control systems, and communication responsiveness. Look for clear information on their available materials and tolerances. Check for customer reviews or case studies, and test their support by asking detailed technical questions before committing to a large project. The best partners act as an extension of your team, providing expert feedback.

Choosing a partner is the most critical first step. I always tell my clients to think of it like hiring an engineer, not just a machine shop. Early in my career, I helped a German robotics company that was getting inconsistent parts from a different online service. The tolerances were all over the place. We took on their project, and the first thing we did was have a detailed video call to review their design for manufacturability (DFM). That communication built the trust they needed.

When you’re evaluating a service, dig deeper than the homepage.

Key Evaluation Criteria

Your evaluation should focus on three main areas: technical skill, quality systems, and customer support. A slick website is nice, but it doesn’t make good parts.

- Technical Capabilities: Can they actually make your part? Don’t just assume they can. Look for specifics. What are their stated standard tolerances? For a client like Alex, who needs ±0.01mm, a service that only promises ±0.1mm is a non-starter. Look at their list of machines (e.g., 3-axis, 5-axis, lathe with live tooling) and the materials they specialize in.

- Quality Assurance Processes: How do they prove the parts are good? Ask for sample inspection reports. Do they offer certifications like ISO 9001? Do they provide material traceability certificates? A reliable service will have a clear, documented process for first-article inspection (FAI), in-process checks, and final inspection.

- Communication and Support: This is huge. Send them a technical question about your design. How quickly do they respond? Is the answer helpful, or just a generic template? The best partners offer DFM feedback to help you optimize your design for cost and function.

I’ve put together a simple table to help you compare potential providers.

| Feature to Compare | What to Look For | Why It Matters |

|---|---|---|

| Tolerance Claims | Specific numbers (e.g., ±0.01mm) vs. vague terms ("high precision"). | Guarantees they can meet your engineering requirements. |

| Material Selection | A wide range of documented metals and plastics with datasheets. | Ensures you can get the exact material properties you need. |

| Inspection Reports | Examples of FAI, CMM reports, or other quality documents. | Proves they have a robust quality system and don’t just "eyeball" it. |

| Customer Support | Fast, technical, and helpful responses. DFM feedback is a bonus. | Shows they are a true partner invested in your success, not just a vendor. |

Don’t be afraid to start with a small prototype order to test a service. It’s a small investment that can save you a massive headache down the line. A good partner will treat your small order with the same importance as a large production run.

What Information Is Crucial for an Accurate CNC Machining Quote?

You’ve spent hours perfecting your design, and now you need a price. But when you upload your file, you get a quote that seems way too high, or the service asks for more information. This back-and-forth wastes valuable time, and incorrect information can lead to inaccurate parts.

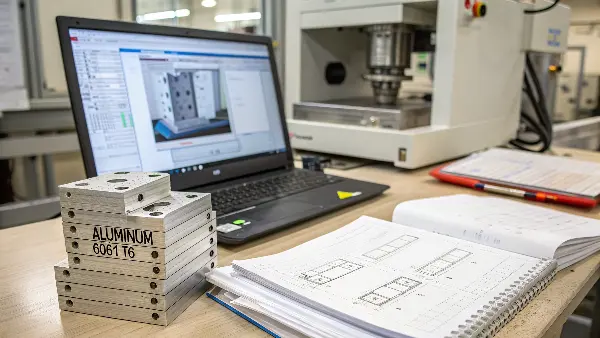

For an accurate CNC machining quote, you must provide a 3D CAD file (STEP is best), a 2D technical drawing with tolerances and critical dimensions, the specific material grade (e.g., Aluminum 6061-T6), the desired surface finish, and the required quantity. Clearly marking critical-to-function features helps the machinist prioritize what matters most, ensuring both accuracy and a fair price.

The quality of your quote depends directly on the quality of the information you provide. Think of it from my perspective on the shop floor: if a drawing is unclear, I have to assume the tightest possible tolerance for every feature, which increases machine time and drives up the cost. Or, I have to stop and ask you questions, which causes delays.

I remember a startup founder who sent us a 3D model with no drawing. The quote was high because our system automatically applied standard tolerances everywhere. I reached out and asked him to mark his three critical dimensions. He sent back a simple PDF with those notes. We requoted, and the price dropped by 30%. Why? Because we didn’t have to spend extra time and a 5-axis machine on non-critical surfaces. Clear communication saves everyone money.

Breaking Down Your RFQ Package

To get the best possible quote, your Request for Quote (RFQ) should be a complete package. Here’s what it must include:

1. 3D CAD Model

This is the master file for programming the CNC machine.

- File Format: STEP (.stp) is the universal standard and is preferred over formats like STL or IGES because it contains more complete geometric data.

- Model Cleanliness: Ensure your model is a single, solid body. Remove any construction lines or surfaces that aren’t part of the final part.

2. 2D Technical Drawing

The 2D drawing provides information the 3D model cannot.

- Tolerances: This is the most important part. Use Geometric Dimensioning and Tolerancing (GD&T) if possible. If not, clearly label tolerances on critical dimensions. For anything not labeled, a title block with standard tolerances (e.g., ISO 2768-m) is essential.

- Threads: Specify thread types and sizes (e.g., M6x1.0).

- Surface Finish: Call out the required roughness (Ra) for specific surfaces.

- Critical Features: Use notes to highlight bores that need a precise fit or surfaces that must be perfectly flat.

3. Essential Administrative Details

Don’t forget the simple stuff. This table shows what you need and why.

| Information | Example | Why It’s Necessary |

|---|---|---|

| Material | Aluminum 7075-T651 | Different alloys have vastly different costs and machinability. |

| Quantity | 10, 50, 200 pcs | Pricing is volume-dependent; providing quantity breaks helps you plan. |

| Surface Finish | Anodized Type II, Black | Finishes add cost and lead time; they must be quoted accurately. |

| Post-Processing | Heat treatment, Assembly | Any work done after machining needs to be included in the quote. |

Putting this information together upfront shows that you are a professional and helps us give you the fastest, most accurate quote. It’s the first step in building a great relationship with your manufacturing partner.

How Are Materials and Finishes Handled in Online CNC Machining?

You’ve designed a part that needs the strength of a specific steel alloy and a durable anodized finish. But how can you be sure the online service will use the exact material you specified and not a cheaper substitute? And will the finish be consistent across all your parts?

Online CNC platforms manage materials by sourcing from qualified suppliers and providing material certifications upon request to guarantee authenticity. Finishes are handled through a network of specialized partners. You select your desired material (e.g., AL 6061-T6) and finish (e.g., Black Anodize Type II) from a menu during the quoting process. The platform’s quality system ensures these specifications are met and verified before shipment.

Material and finish selection is not just about aesthetics; it’s about function. I once worked on a project for a medical device company. Their part was made from 316L stainless steel because of its biocompatibility. The client was worried that a contractor might accidentally use 304 stainless, which looks similar but is not suitable for medical implants. We implemented a strict material tracking process, from receiving the raw bar stock with certifications to engraving a lot number on each finished part. This gave the client complete peace of mind.

This is the level of detail a good online service should provide. They are your proxy, managing the physical supply chain for you.

Material Selection and Verification

When you order online, you’re trusting the service to get the material right. Here’s how it should work:

- Clear Selection: The platform should offer a clear list of available materials, including specific grades (e.g., not just "Aluminum," but "Aluminum 6061-T6," "Aluminum 7075-T6," etc.). Many will even provide links to material datasheets so you can check properties like tensile strength and hardness.

- Material Certification: For any critical application, you should be able to request a material certificate. This document (often called a Mill Test Report or MTR) comes from the material supplier and proves the chemical composition and mechanical properties of the raw stock used for your parts. At QuickCNCs, we offer these for almost every metal we machine.

Managing Surface Finishes

Surface finishing is often done by a separate, specialized partner. A good online CNC service manages this process seamlessly.

- Standard Finishes: Most platforms offer a standard menu of finishes. Understanding what they mean is key.

| Finish Type | Description | Common Use Case |

|---|---|---|

| As Machined | The standard finish left by the cutting tool. Typically has visible tool marks. | For functional prototypes or parts where cosmetics don’t matter. |

| Bead Blasting | Creates a uniform, non-reflective matte or satin finish by blasting with fine glass beads. | Hides tool marks and provides a consistent cosmetic appearance. |

| Anodizing (Type II) | An electrochemical process that creates a durable, corrosion-resistant, decorative oxide layer on aluminum. | Adds color and protects aluminum parts from wear and corrosion. |

| Hardcoat Anodizing (Type III) | A thicker, denser form of anodizing that provides superior wear and corrosion resistance. | For functional parts in high-wear applications, like robotic joints. |

| Powder Coating | A durable paint-like finish applied as a dry powder and cured with heat. | Provides a tough, decorative finish on metals in a wide range of colors. |

- Quality Control for Finishes: Consistency is crucial. Your provider should have quality checks for finishes, such as checking color against a sample (e.g., a RAL color code) and measuring the thickness of coatings like anodizing to ensure they meet the specification. It is this attention to detail that separates a great service from an average one.

What Does Quality Assurance Look Like for Remote CNC Orders?

You’ve placed an order with an online service thousands of miles away. How can you be sure the parts you receive will meet your tight tolerances? You can’t just walk down to the shop floor to inspect them yourself. This lack of control can feel unnerving, especially for critical components.

Quality assurance for remote CNC orders relies on a documented, multi-step inspection process. This includes a First Article Inspection (FAI) on the first part produced, in-process checks during the production run, and a final 100% or sampled inspection before shipping. Results are documented in a formal inspection report, often using CMM data, which is then sent to you for approval.

I can’t stress this enough: trust is built on proof. It’s not enough for me to say your parts are good. I have to show you. I remember a new client, an engineer like Alex in Germany, who was designing parts for a high-performance robotic arm. The tolerances for the bearing bores were ±0.005mm. He was naturally skeptical about ordering them from China.

For his first order, we documented every step. We sent him photos of the raw material certs. We produced one part, performed a full CMM inspection, and emailed him the detailed report overnight. He was able to review the 3D scan data on his computer in Germany before we machined the other 49 pieces. This transparency gave him the confidence to approve the full production run.

The Stages of Remote Quality Control

A robust QA process for online orders should include several key stages. Don’t be afraid to ask a potential supplier what their standard process is.

1. First Article Inspection (FAI)

This is the most critical step. The very first part off the machine is taken and subjected to a full dimensional inspection against the 2D drawing. Every single dimension, tolerance, and feature is checked and recorded.

- For simple parts: This might be done with calipers, micrometers, and height gauges.

- For complex parts: This is where a Coordinate Measuring Machine (CMM) is essential. A CMM uses a probe to take precise measurements of the part’s geometry, comparing it directly to the CAD model. The output is a detailed report that shows every measured dimension and how it deviates from the nominal.

2. In-Process Quality Control (IPQC)

Quality can’t just be checked at the end. During the production run, operators should be periodically checking critical features. This catches any issues—like tool wear causing dimensions to drift—before a large number of bad parts are made. This proactive approach saves time and material.

3. Final Inspection

Before the parts are packed, they go through a final inspection.

- Sampling vs. 100% Inspection: Depending on the quantity and criticality, this could be a statistical sampling (e.g., checking 10 parts out of 100 based on an AQL standard) or a 100% inspection of every part. For Alex’s robotic arm components, we would do a 100% inspection of the critical bearing bores.

- The Inspection Report: This is your proof of quality. The final report should summarize the findings of the final inspection and be included with the shipment or emailed to you.

| Inspection Stage | Purpose | Key Tool/Document |

|---|---|---|

| FAI | Verify the machine setup and program are correct before mass production. | CMM Report / FAI Report |

| IPQC | Monitor and control quality during the production run to prevent drift. | Operator Checklists, Calipers |

| Final Inspection | Confirm the entire batch meets specifications before shipping. | Final Inspection Report |

When you work with a remote supplier, their inspection report is your eyes on the shop floor. Always insist on one.

Conclusion

In summary, online CNC services simplify getting custom parts. Success depends on choosing a good partner, providing clear specifications, and verifying quality through documented inspections.