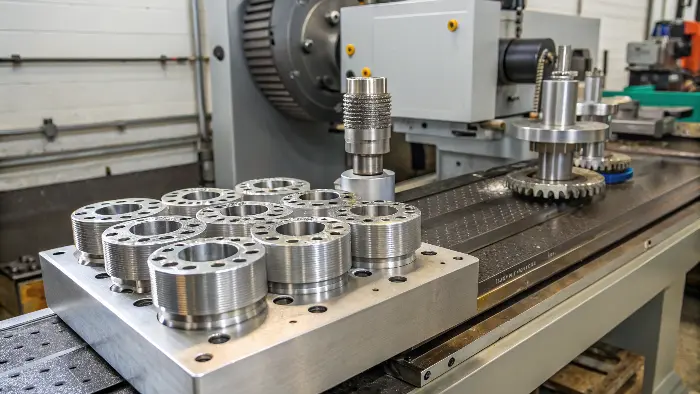

Are your CNC machined parts consistently over budget or facing production delays? Complex designs often translate to manufacturing headaches. Applying Design for Manufacturability (DFM) principles early can prevent these costly problems and streamline your entire production process.

DFM for CNC mills and lathes means designing parts with the manufacturing process in mind from the very start. This involves considering tool access, material properties, standard component sizes, and appropriate tolerances. Implementing DFM early significantly reduces production costs, improves the quality of your parts, and shortens lead times for your custom machined components.

As an engineer or product developer, you want your designs to be both functional and efficient to produce. I’ve seen countless projects at QuickCNCs where a few DFM tweaks made a world of difference. It’s not about compromising your design’s integrity; it’s about making smart choices that align with manufacturing capabilities. Let’s explore how DFM can specifically benefit your CNC milled and lathed parts, ensuring you get the best results without unnecessary expense or delays. Understanding these principles will empower you to create better, more cost-effective designs.

What Key DFM Principles Should You Consider for CNC Milling?

Designing parts for CNC milling without thinking about how they’ll be made can lead to complex setups and long machining times. This often inflates costs and can even make a design impossible to machine. DFM for milling simplifies production significantly.

Key DFM principles for CNC milling include designing for standard tool sizes, minimizing the number of setups required, avoiding deep pockets with small internal radii, and ensuring all features are easily accessible to cutting tools. Adhering to these guidelines makes parts easier, faster, and cheaper to produce on a CNC mill.

When I work with clients like Alex, a meticulous engineer from Germany, we often discuss these DFM points for his robotic components. For CNC milling, one of the first things to consider is standard tool sizes. Designing pockets and slots that can be cut with common end mill diameters, say 6mm or 10mm, is much more cost-effective than requiring custom or very small tools. Another crucial aspect is minimizing setups. Each time a part needs to be re-fixtured to machine a different face, it adds time and potential for error. Try to orient features so they can be machined from the fewest sides possible. Internal radii are also a big one; sharp internal corners are impossible with a round cutting tool. Always design internal corners with a radius slightly larger than the tool radius you anticipate being used. For example, if a 6mm end mill is used, the internal radius should be at least R3.5mm or R4mm. Finally, tool access is paramount. Avoid features hidden deep within a part or obstructed by other elements, as these may require specialized long-reach tools or complex 5-axis machining, driving up costs. Uniform wall thickness also helps prevent warping and improves stability during machining.

| DFM Principle for Milling | Recommendation | Benefit |

|---|---|---|

| Standard Tool Sizes | Use common cutter diameters | Reduces tool cost and setup time |

| Minimize Setups | Design features accessible from fewer sides | Lowers labor cost, improves accuracy |

| Internal Radii | Make radii larger than tool radius | Avoids custom tooling, speeds machining |

| Tool Access | Ensure features are easily reachable | Simplifies machining, reduces complexity |

| Uniform Wall Thickness | Avoid overly thin or varying wall sections | Prevents distortion, improves stability |

How Does DFM Streamline CNC Turning Operations?

CNC turned, or lathed, parts can become surprisingly complex and expensive if DFM isn’t considered during the design phase. Features like very long, thin sections or intricate internal profiles can cause significant machining challenges. Applying DFM for turning streamlines the entire process.

DFM for CNC turning primarily focuses on maintaining part rigidity, utilizing standard cutting tools, avoiding sharp internal corners by using radii or undercuts, and simplifying grooves or threads. These considerations ensure efficient material removal, better surface finishes, and overall cost-effectiveness for cylindrical parts.

For turned parts, which are common in many mechanical systems, DFM plays a slightly different but equally important role. Part rigidity is a major concern. Long, slender parts (with a high length-to-diameter ratio, say greater than 10:1) can deflect under cutting forces, leading to inaccuracies or chatter. Sometimes, a tailstock or steady rest can help, but designing for inherent stiffness is better. Using standard tooling is also key. Lathes use inserts of various shapes and sizes; designing features that can be machined with common insert geometries saves on custom tool costs. For internal corners, similar to milling, sharp corners are problematic. It’s better to design an undercut or a radius. If a sharp corner is absolutely needed where two diameters meet, an undercut allows the tool to clear the corner, ensuring the adjacent face is machined correctly. When designing grooves and threads, stick to standard profiles and sizes whenever possible. Ensure there’s adequate relief for threading tools, especially for internal threads. Also, consider the depth and width of grooves; very deep and narrow grooves can be challenging and may require specialized tooling. I always advise clients to think about how the part will be gripped in the chuck; providing a suitable clamping surface can simplify setups.

| DFM Principle for Turning | Recommendation | Benefit |

|---|---|---|

| Part Rigidity | Maintain a low length-to-diameter ratio | Reduces deflection, improves accuracy |

| Standard Tooling | Design for common insert shapes/sizes | Lowers tool cost, ensures availability |

| Internal Corners | Use radii or undercuts | Simplifies machining, avoids tool breakage |

| Grooves/Threads | Use standard profiles, provide relief | Ensures compatibility, easier to machine |

| Workholding | Design with clear clamping surfaces in mind | Simplifies setup, improves machining stability |

Why is Choosing the Right Material a Cornerstone of DFM for CNC?

Selecting an inappropriate material can turn your CNC machining project into a costly nightmare. Hard-to-machine materials wear out tools quickly, while some softer ones can be gummy and difficult to achieve good finishes on. This directly impacts cost, machining time, and the final part quality.

Material selection is a vital aspect of DFM because it directly influences machinability, tool life, achievable cutting speeds, surface finish, and ultimately, the overall cost of production. Choosing a material that effectively balances the required performance characteristics with ease of machining is key for successful and economical CNC production.

At QuickCNCs, we often guide engineers through material selection. It’s not just about the material’s end-use properties but also its machinability. Materials like Aluminum 6061 are highly machinable, meaning they can be cut quickly with good tool life and surface finish. Steels like 304 Stainless Steel are tougher, requiring slower speeds and more robust tooling, which increases machining time and cost. Exotic alloys or hardened steels present even greater challenges. The material choice directly impacts tool wear and the frequency of tool changes, adding to downtime and expense. The achievable tolerances and surface finishes can also vary with material. Softer materials might struggle to hold very tight tolerances or achieve a mirror finish without secondary operations. The cost of the raw material itself is a factor, but often the machining cost outweighs it, especially for complex parts or difficult materials. I remember a project where a client initially specified a very tough nickel alloy for a non-critical component. After discussion, we switched to a more machinable stainless steel that still met performance needs, saving nearly 40% on machining costs. Always consider if a more common, easier-to-machine material can meet your design requirements.

| Material Aspect | DFM Consideration | Impact |

|---|---|---|

| Machinability Rating | Prefer materials with higher machinability | Faster cycle times, lower tool wear, reduced cost |

| Hardness/Toughness | Balance strength needs with machining difficulty | Harder materials increase machining time and tool costs |

| Cost of Raw Material | Consider alongside machining cost | Sometimes a cheaper material is much more expensive to machine |

| Finish Requirements | Some materials achieve better finishes more easily | May reduce need for secondary finishing operations |

| Heat Treatment | Factor in post-machining treatments if shape changes | Can affect final dimensions and tolerances |

How Do Tolerances and Surface Finishes Affect CNC Machinability and Cost?

It’s a common habit for engineers to specify very tight tolerances on drawings. However, unnecessarily tight tolerances and super-fine surface finishes can drastically increase machining time, complexity, and scrap rates. This makes projects significantly more expensive and slower.

Tolerances and surface finish specifications significantly impact CNC machining costs. Tighter tolerances and finer finishes require more precise machining processes, slower cutting speeds, potentially specialized tooling or extra operations like grinding, and more rigorous inspection, all adding to the expense. Specify them only as tight or fine as functionally necessary.

This is a topic I discuss almost daily. The relationship between tolerance and cost is often exponential. Halving a tolerance doesn’t just double the cost; it can triple or quadruple it. For example, a standard tolerance of ±0.1mm might be easily achieved in one pass. But tightening that to ±0.01mm could require multiple fine passes, specialized metrology, and even a climate-controlled environment. It’s crucial to distinguish between critical and non-critical dimensions. Apply tight tolerances only where they are functionally essential for the part’s assembly or performance. For other features, use standard workshop tolerances. Similarly, demanding a very fine surface finish (e.g., Ra 0.4μm) when Ra 1.6μm or Ra 3.2μm would suffice adds unnecessary cost. Achieving smoother finishes often means slower feed rates, specific tooling, or secondary operations like polishing or grinding. I always encourage clients like Alex, who designs high-precision robotic parts, to clearly mark critical-to-function dimensions and discuss realistic surface finish needs. Using Geometric Dimensioning and Tolerancing (GD&T) effectively can also help, as it defines permissible variation in form, orientation, and location, often allowing for looser individual tolerances while ensuring functional fit.

| Specification | DFM Consideration | Cost Impact |

|---|---|---|

| Dimensional Tolerance | Specify only as tight as functionally required | Tighter tolerances exponentially increase machining time and cost |

| Surface Finish (Ra) | Define based on functional need, not aesthetics alone | Finer finishes require slower machining or secondary operations |

| GD&T | Use appropriately to define functional requirements | Can optimize tolerances, but complex GD&T can also increase inspection |

| Inspection | Tighter specs mean more inspection time and cost | Consider how features will be measured |

| Standard vs. Precision | Understand the cost jump between these levels | Precision machining involves more care, better tools, and slower rates |

Conclusion

Applying DFM principles to your CNC milled and lathed parts isn’t an extra step; it’s fundamental to efficient and cost-effective manufacturing. By considering these guidelines early in your design process, you can save time, reduce costs, and improve the overall quality of your components.