Are your machining cycle times too long? Traditional methods can be slow, impacting your deadlines and costs. High-Speed Machining offers a powerful solution to accelerate production.

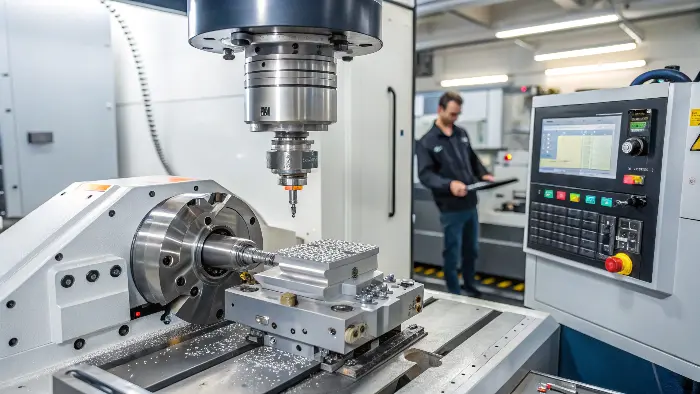

High-Speed Machining (HSM) is a modern manufacturing technique. It uses high spindle speeds, fast feed rates, and optimized toolpaths. This achieves much higher material removal rates and shorter machining cycles, revolutionizing precision part production.

When I first encountered High-Speed Machining, it felt like a game-changer. The ability to cut faster and achieve better finishes seemed almost too good to be true. But, like any advanced technique, understanding its core ideas and how to apply them correctly is key. It’s not just about cranking up the speed; it’s a systematic approach. Let’s explore what makes HSM tick and how you can make it work for you.

What are the Core Principles Behind High-Speed Machining?

Confused by all the talk about HSM? It might seem complex, but its foundation rests on a few key, understandable principles that work together for impressive results.

HSM relies on very high spindle speeds (often over 15,000 RPM), rapid feed rates, and smart, dynamic toolpaths. It also demands minimized tool deflection, precise tool balancing, and secure work holding for optimal performance.

From my experience in the shop, mastering HSM starts with grasping its fundamental principles. It’s more than just speed; it’s about intelligent application of force and motion.

First, High Spindle Speeds are a hallmark. We’re talking speeds typically exceeding 15,000 RPM, and often reaching 40,000 RPM or even higher. This allows for much faster cutting speeds.

Coupled with this are Rapid Feed Rates. High spindle speeds alone aren’t enough; the tool needs to move through the material quickly and efficiently.

Then there are Dynamic Toolpaths. This is where modern CAM software shines. HSM uses advanced strategies like trochoidal milling, adaptive clearing, and high-efficiency milling. These paths optimize how the tool engages with the material, improve chip evacuation, and crucially, minimize heat buildup. I’ve seen firsthand how a well-programmed toolpath can dramatically improve performance.

Minimizing Tool Deflection is also vital. Rigidity throughout the entire setup – the machine tool itself, the workholding, and the tool holding – is critical. Any excessive deflection ruins accuracy and can lead to tool breakage.

Precise Tool Balancing becomes non-negotiable at high RPMs. Even small imbalances can cause significant vibrations, poor surface finish, and premature spindle wear.

Finally, Proper Clamping Methods and the concept of Chip Thinning (using a smaller radial depth of cut to reduce chip thickness, allowing for increased feed rates) are integral.

| HSM Principle | Description | Impact |

|---|---|---|

| High Spindle Speeds | >15,000 RPM, often up to 40,000+ RPM | Higher cutting speeds, shorter cycle times |

| Rapid Feed Rates | Fast tool movement through material | Efficient material removal |

| Dynamic Toolpaths | Trochoidal, adaptive milling, etc. | Optimized tool engagement, reduced heat |

| Minimized Tool Deflection | Rigidity in machine, workholding, tool holding | Ensures accuracy and repeatability |

| Precise Tool Balancing | Tools balanced for high RPMs | Minimizes vibration, ensures smooth operation |

| Chip Thinning | Smaller radial depth of cut (RDOC) for thinner chips at higher feeds | Improved feed rates, longer tool life |

What Key Advantages Does High-Speed Machining Offer?

Wondering if HSM is worth the investment? The benefits go far beyond just speed, impacting quality, tool longevity, and the types of materials you can effectively process.

HSM significantly boosts productivity with shorter machining cycles. It also delivers superior surface finishes and tighter dimensional accuracy, often reducing the need for secondary finishing operations.

The advantages of implementing HSM are compelling, and I’ve seen them transform operations for many clients. The most obvious is Increased Productivity. By dramatically shortening machining cycle times, you get parts out the door faster, increasing overall throughput. This was a huge factor when I helped a client in the aerospace sector reduce lead times for complex aluminum components.

Next is Superior Surface Quality and Accuracy. The combination of high cutting speeds and controlled, light cuts often results in finer surface finishes and tighter dimensional tolerances. This can reduce or even eliminate the need for secondary operations like grinding or polishing, saving time and cost.

Surprisingly to some, HSM can lead to Extended Tool Life. While it seems counterintuitive that higher speeds would mean longer life, HSM uses advanced tool materials, coatings, and efficient chip evacuation. The principle of "chip thinning" and keeping the tool constantly engaged with light cuts reduces the stress and heat on the cutting edge.

This leads to Reduced Heat Generation in the workpiece. Because the cutting speeds are so high, much of the heat generated is expelled with the chips, rather than soaking into the part. This minimizes thermal distortion and residual stresses, which is critical for precision components.

HSM also allows for Improved Machining of Difficult Materials. I’ve found it particularly effective for materials like hardened steels, titanium alloys, and composites, which can be a real headache with conventional methods.

Finally, all these factors contribute to Increased Dimensional Accuracy by minimizing tool deflection and thermal effects.

What are the Potential Drawbacks or Challenges of High-Speed Machining?

HSM sounds incredibly promising, but what’s the catch? Like any advanced technology, it comes with its own set of considerations and potential hurdles to overcome for successful implementation.

HSM can involve a significant initial investment in specialized equipment. It also demands highly skilled operators and programmers, and presents challenges like vibration and tool pull-out if not managed correctly.

While the benefits of HSM are substantial, it’s important to be aware of the potential challenges. It’s not a simple plug-and-play solution.

One of the first hurdles is the Initial Investment. True HSM-capable machines with high-speed spindles, robust construction, and advanced control systems can be expensive. This was a big discussion point when I advised a startup on their first major equipment purchase.

Then there’s the need for Skilled Personnel. Programming effective HSM toolpaths requires specialized CAM software and operators who understand the nuances of high-speed cutting dynamics. Training is often necessary.

Vibration and Chatter can be major issues if the machine, tooling, or workholding isn’t sufficiently rigid or if tools are not properly balanced. At high speeds, even minor imbalances or flex can lead to poor surface finish or tool failure. I always recommend performing harmonic testing on new setups.

Tool Pull-Out is a risk with some types of tool holders at very high RPMs if not selected and maintained correctly. Specialized high-performance chucks are often required.

For certain materials, Work Hardening can be exacerbated if parameters aren’t optimized, especially if the tool dwells or rubs instead of cutting cleanly.

The sheer volume of data processing for complex HSM toolpaths also means you need Powerful Control Systems on your machines.

Addressing these challenges proactively is key. It means careful planning, investing in the right technology and training, and paying close attention to every detail of the setup.

How Do You Effectively Implement High-Speed Machining Strategies?

Ready to harness the power of HSM? Successful implementation requires more than just a fast machine; it demands a holistic approach, integrating equipment, software, tooling, and process knowledge.

Effectively implement HSM by investing in capable machines, optimizing CAM programming with specific HSM strategies, selecting appropriate high-performance tooling, ensuring robust cooling, and using rigid, balanced workholding.

Implementing HSM successfully is a journey I’ve guided many clients through. It’s about bringing several key elements together.

First, you need to Invest in Suitable Equipment. This means machines designed for HSM, featuring high-speed spindles (with good thermal stability), a rigid and well-damped structure, and fast, accurate control systems capable of handling complex toolpaths and rapid accelerations/decelerations.

Next, Optimize CAM Programming. This is crucial. Advanced CAM software with dedicated HSM modules is essential. Strategies like trochoidal milling, peel milling, and constant tool engagement angle (CEA) are vital for generating efficient and safe toolpaths. I always emphasize to my team that the CAM program is the brain of the HSM operation.

Select Appropriate Tooling. This involves choosing tools with the right geometry (e.g., for chip thinning), made from suitable materials (like fine-grain carbide or ceramics, often with advanced coatings), and, critically, ensuring they are balanced for high-speed operation.

Implement Effective Cooling and Lubrication. High-pressure through-spindle coolant systems or Minimum Quantity Lubrication (MQL) are often necessary to control heat, flush chips effectively, and reduce tool wear.

Ensure Proper Workpiece and Tool Holding. Rigidity is king. Use high-quality, balanced tool holders (like shrink-fit or hydraulic chucks) and robust fixturing for the workpiece to minimize vibration and ensure stability.

Finally, it’s about adopting a Holistic Approach. Successful HSM isn’t just about one component; it’s about the synergy between the machine tool, cutting tools, tool holders, CAM software, and the operator’s skill. Continuously monitoring the process, being prepared to make adjustments, and learning from each job are all part of making HSM a true asset in your manufacturing arsenal.

Conclusion

High-Speed Machining, when understood and implemented correctly, offers transformative benefits in productivity, quality, and capability, making it a vital strategy for modern precision manufacturing.