Confusing automotive terms like drive shaft and transmission shaft can lead to costly design or procurement errors. Misidentifying these parts can derail your project, causing delays and budget overruns. Understanding their distinct roles is key to precision engineering and successful project outcomes.

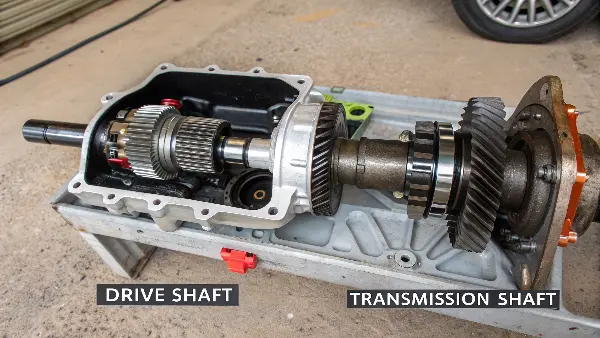

A transmission shaft, also known as a mainshaft, operates inside the transmission gearbox, transferring power through various gear sets to alter speed and torque. In contrast, a drive shaft is a separate, external component that transmits this power from the transmission’s output to the differential, which then turns the wheels. They are fundamentally different parts serving distinct functions in the powertrain.

These terms are often a source of confusion, not just for enthusiasts but sometimes for new engineers as well. In my years of helping clients source and machine custom parts, I’ve seen how a simple mix-up in terminology can lead to incorrect quotes, wrong parts being manufactured, and frustrating delays. For an engineer like you, precision in language is just as critical as precision in measurements. Let’s break down each component, one by one, so you can specify your powertrain needs with absolute confidence and avoid these common pitfalls.

What is the difference between a drive shaft and a transmission shaft?

You need to specify a shaft for a powertrain system, but you’re not 100% sure of the correct terminology. Using the wrong term could lead to sourcing the wrong component, which wastes valuable time, money, and engineering resources. Let’s clarify the fundamental differences right now.

The primary difference is their location and function. A transmission shaft is an internal gearbox component that transmits power through different gear ratios. A drive shaft is an external component that connects the transmission output to the differential, delivering final rotational power to the wheels. They are not interchangeable and are designed for entirely separate roles.

To truly grasp the distinction, we need to look closer at where they live and what they do. I’ve machined countless versions of both, and their design differences tell the whole story. The requests I get for each are completely different, from the material callouts to the specific features that require tight tolerances.

Location Defines the Name

The simplest way to tell them apart is by their location relative to the gearbox housing.

- Transmission Shafts: These are found inside the sealed transmission case. They are bathed in gear oil and work in direct contact with the gears. A manual transmission typically has at least three: an input shaft from the clutch, a countershaft (or layshaft), and a mainshaft (or output shaft).

- Drive Shaft: This component exists outside the transmission. It’s the long, tubular shaft you can see running down the center of the underbody on most rear-wheel-drive or all-wheel-drive vehicles. It acts as a bridge, connecting the transmission’s output to the rear differential.

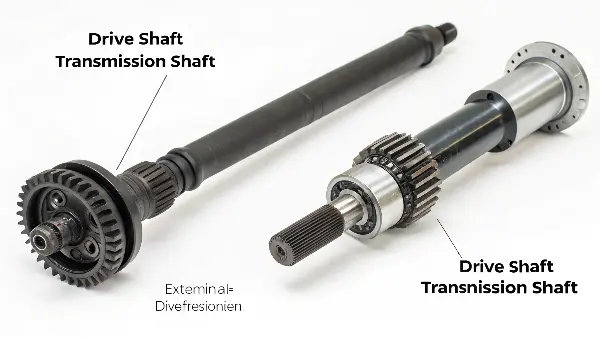

Functional Roles and Design

Their jobs are fundamentally different, which dictates their design. A transmission shaft is a gear selector. As you shift gears, different cogs on the mainshaft are engaged, changing the speed-to-torque ratio. Because of this, transmission shafts I’ve machined often feature complex integrated splines and gear teeth, requiring precise 5-axis CNC machining to create.

The drive shaft has a simpler job: deliver the power. It takes the final output from the transmission and just spins, turning the differential. Its main design challenges are strength, weight, and balance. It must be strong enough to handle the engine’s full torque but light enough to minimize rotational inertia. Most importantly, it has to be perfectly balanced. I remember a project where an imbalance of just a few grams on a drive shaft caused a horrible vibration at highway speeds. We had to re-balance it on a special rig to solve the problem. This is why drive shafts are often simple, hollow tubes—for strength-to-weight ratio—with welded yokes for the universal joints.

Here is a simple table to summarize the key differences:

| Feature | Transmission Shaft (Mainshaft) | Drive Shaft (Propeller Shaft) |

|---|---|---|

| Location | Inside the transmission gearbox | Between the transmission and differential |

| Primary Function | Transmits power through selectable gears | Transmits final power to the differential |

| Environment | Bathed in transmission fluid | Exposed to road elements |

| Common Design | Solid, with integrated splines and gears | Hollow tube with universal joints at ends |

| Key Challenge | Gear/spline manufacturing precision | Strength, weight, and rotational balance |

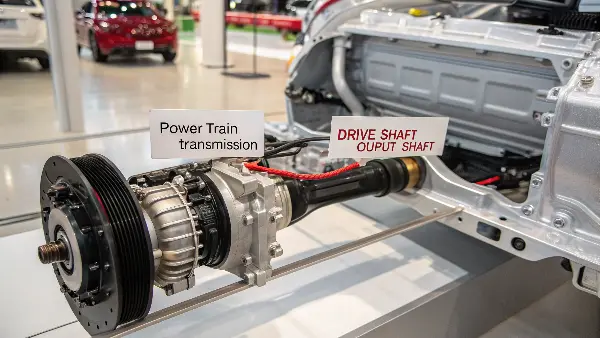

Is the drive shaft part of the transmission?

Trying to understand how all the powertrain components fit together can feel like solving a complex puzzle. Thinking the drive shaft is an integral part of the transmission itself can confuse your understanding of the system’s architecture and how power flows from the engine to the road.

No, the drive shaft is not considered an internal part of the transmission assembly. It is a distinct and separate component that connects to the transmission’s output shaft. The transmission is a self-contained gearbox with its own shafts (input, counter, mainshaft) that manage gear ratios. The drive shaft’s job begins where the transmission’s job ends.

Visualizing the powertrain as a chain of distinct links is the best way to understand this relationship. Each link has a specific job, and it hands off the power to the next one in line. The drive shaft is a critical link in this chain, but it is not part of the transmission link.

The Powertrain Chain of Command

Let’s trace the flow of power from the engine. It’s a clear, sequential path.

Engine → Clutch → Transmission → Drive Shaft → Differential → Axle Shafts → Wheels

As you can see, the transmission is one complete system, and the drive shaft is the very next system in the chain.

The Transmission: A Self-Contained Gearbox

Think of the transmission as a "black box" (or, more accurately, a cast aluminum box). Its sole purpose is to take the single-speed, high-torque output from the engine and convert it into various speed and torque combinations for the driver to select. It does this using a complex set of internal gears and shafts. When its job is done, it provides a single rotating output on a flange or yoke. This is where its responsibility ends.

I once worked with an engineer from Germany, Alex, who was designing a custom chassis for an electric vehicle conversion. He carefully allocated space for the motor and transmission but made a critical assumption. He treated the drive shaft as an afterthought, almost like an accessory of the transmission. When it came time for assembly, the drive shaft angle was too steep, causing the universal joints to bind. We had to work with him to re-engineer the transmission mounts and modify the floor pan to create a viable angle. That taught me a valuable lesson: always visualize the entire power flow, from the motor to the wheels. The drive shaft isn’t part of the gearbox; it’s the crucial bridge that makes the whole system work. It needs its own space and geometric considerations in any design.

What is the difference between a drive shaft and a cardan shaft?

You are reading technical diagrams or communicating with global suppliers, and you see the terms "drive shaft" and "Cardan shaft" used, sometimes seeming to refer to the same part. This can create confusion and make you wonder if you’re missing a key technical distinction.

Functionally, there is often no difference; they are the same component. "Cardan shaft" is a more technical term that specifically refers to a drive shaft utilizing Cardan joints (a common type of universal joint). Since most drive shafts use these joints, the terms "drive shaft," "propeller shaft," and "Cardan shaft" are used interchangeably in the automotive world.

This is one of those cases where a component is named after its function ("drive shaft") and also after its key enabling technology ("Cardan shaft"). Understanding the origin of the name "Cardan" makes everything clear.

The Genius of the Cardan Joint

A drive shaft has a tough job. It must connect the transmission, which is fixed to the chassis, with the differential, which moves up and down with the suspension. This means the angle between the transmission and the differential is constantly changing. How can you transmit smooth, rotational power through a constantly changing angle?

The answer is the universal joint, or U-joint. The most common type of U-joint is the Cardan joint, named after the 16th-century Italian mathematician Gerolamo Cardano, who first described the concept. This joint uses a cross-shaped spider bearing to connect two yokes, allowing one to pivot relative to the other on two axes. By placing a Cardan joint at each end of a shaft, you can transmit torque smoothly even when the shaft is operating at an angle.

A Matter of Terminology, Not Function

So, a "Cardan shaft" is simply a shaft equipped with Cardan joints. Since this is the standard solution for almost every rear-wheel-drive car, the name became synonymous with "drive shaft."

In my experience, terminology often varies by region and engineering discipline.

- Drive Shaft: The most common term in North America. Simple, descriptive, and universally understood.

- Propeller Shaft (or Propshaft): Very common in the UK and other parts of Europe. It has the same meaning as a drive shaft.

- Cardan Shaft (or Kardanwelle): Often preferred by German engineers and in more academic or technical texts. It’s more precise because it describes how the shaft works.

When I talk with my clients, I adapt my language. If I’m speaking with Alex in Germany, I’ll probably use "Kardanwelle" because it aligns with his technical vocabulary. If I’m talking to a team in the US, I’ll stick with "drive shaft." The important thing is that we all understand we’re talking about the same component: the spinning rod with U-joints that delivers power to the wheels. At the end of the day, the CNC machine doesn’t care what you call it, as long as the dimensions on the blueprint are correct.

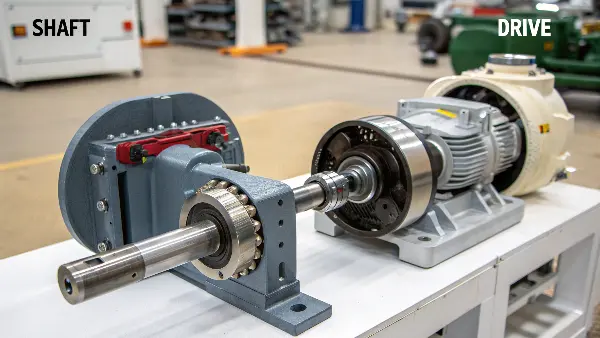

What is the difference between drive and shaft?

Sometimes the most basic engineering terms can be the most confusing if not clearly defined. You know what a "drive" is and you know what a "shaft" is, but understanding their precise relationship is fundamental. Being unclear on these core concepts can undermine your technical confidence.

A "shaft" is a specific mechanical component: a rotating rod used to transmit torque and motion. A "drive" is a much broader term referring to the entire system or mechanism that provides motion. Therefore, a shaft is almost always a single component within a larger drive system. For instance, a "belt drive" system uses shafts, pulleys, and a belt.

Let’s break this down with a simple analogy. Think of it like this: a "brick" is a single object. A "wall" is the system you build using many bricks. The relationship between "shaft" and "drive" is very similar.

Shaft: The Component

A shaft is a fundamental building block in mechanical engineering. It’s the physical part, the piece of metal (or composite) that you can hold in your hand. Its primary job is to rotate and carry torque. There are many types of shafts, all named for their specific role in a larger machine:

- Crankshaft: Converts the linear motion of pistons into rotation.

- Camshaft: Opens and closes engine valves.

- Transmission Shaft: Carries gears inside a gearbox.

- Drive Shaft: Transmits power from the gearbox to the differential.

- Axle Shaft: Delivers power from the differential to the wheels.

In my CNC shop, we make these "bricks." We take a solid piece of steel or aluminum and machine it to incredibly tight tolerances, knowing it has to perform its specific role perfectly.

Drive: The System

A "drive" or "drivetrain" is the complete assembly of components that work together to transmit power. It’s the "how," not the "what." It describes the method of power transmission. For example:

- Chain Drive: Uses sprockets and a chain (like on a bicycle).

- Belt Drive: Uses pulleys and a belt (like the serpentine belt on an engine).

- Gear Drive: Uses intermeshing gears to transmit motion directly.

- Direct Drive: The motor is connected directly to the driven part, often with a simple shaft.

Here’s a table that breaks down the concept:

| The "What" (Physical Components) | The "How" (The System/Method) |

|---|---|

| Shaft, Gear, Sprocket, Belt, Pulley, Chain | Gear Drive, Belt Drive, Chain Drive |

| Drive Shaft, Transmission, Differential, Axles | Drivetrain (The car’s complete power delivery system) |

So, a "drive shaft" is a specific type of shaft that is a key component in the vehicle’s drivetrain. Mastering this basic distinction makes technical conversations clearer and your understanding of any mechanical system much deeper.

Conclusion

In engineering, precise terminology is vital. Understanding that transmission shafts work inside the gearbox and drive shafts connect it to the wheels is key to successful design and sourcing.