Exotic metals offer amazing strength, but their high price can wreck your budget. This often forces a search for cheaper options without losing key performance. I’m here to show you how.

You can find cost-effective alternatives by considering high-strength steels, advanced aluminum alloys, and even non-metal options like composites or ceramics. Smart design and manufacturing choices also play a big role in saving money.

I’ve spent over a decade helping engineers like Alex in Germany source CNC machined parts. While materials like titanium and superalloys are incredible, their cost often sends us looking for more practical solutions. The good news is, there are many ways to achieve great strength and performance without paying premium prices. It’s about understanding the trade-offs and knowing where to look. Let’s explore some of these practical alternatives that can keep your project on budget and on track.

What is a Cheap but Strong Metal That Can Replace Exotics?

You need strength, but exotic metal prices are a shock. This search for affordable power can feel frustrating, leading to project delays or compromises.

High-strength steels, including various alloy steels and Advanced High-Strength Steels (AHSS), offer excellent strength, fatigue resistance, and toughness at a significantly lower cost than exotic metals. They are a top choice for many demanding applications.

When engineers ask me for a "cheap but strong" metal, my mind often goes straight to steel. It’s the workhorse of the industry for a reason. I’ve seen countless projects where a well-chosen steel alloy provided all the necessary performance without the exotic price tag. It’s about finding the right grade for your specific needs.

Understanding High-Strength Steel Alloys

When we talk about high-strength steels, it’s not just one material. It’s a broad family. Alloy steels, like 4140 or 4340, are common choices. They contain elements like chromium, molybdenum, and manganese, which enhance their properties. After proper heat treatment, these steels can achieve impressive tensile and yield strengths, making them suitable for gears, shafts, and structural components. I remember a client who was considering a very expensive specialty alloy for a load-bearing pin. We switched to heat-treated 4140 steel, saved them a huge amount on material costs, and the part performed perfectly. The key is understanding the heat treatment process and how it can unlock the steel’s potential. These materials are very common in industries ranging from automotive to industrial machinery.

The Rise of Advanced High-Strength Steels (AHSS)

Beyond traditional alloy steels, there’s a newer category called Advanced High-Strength Steels (AHSS). These include grades like Dual Phase (DP), Transformation-Induced Plasticity (TRIP), and Martensitic steels. AHSS offers even higher strength levels, often combined with good formability, making them excellent for applications where weight reduction is also a goal, such as automotive body structures. While they might be a bit more specialized than common alloy steels, their cost is still far below exotic metals. I’ve seen AHSS used effectively for components needing high impact resistance and energy absorption. Their complex microstructures provide a unique combination of properties that can be very beneficial.

Applications and Cost Benefits

The beauty of these steels is their versatility and cost-effectiveness. You can find a steel alloy suitable for an incredible range of applications – from simple brackets to complex machinery parts, aircraft components, and structural elements needing high load-bearing capacity. At QuickCNCs, we machine a lot of different steel grades. The raw material cost is significantly lower than titanium or nickel-based superalloys. Machining can sometimes be a bit more challenging than, say, aluminum, but modern tooling and techniques handle it well. The overall part cost is usually much more attractive, allowing companies to produce strong, reliable components without overspending. This is why steel remains a dominant material in so many engineering fields.

Beyond Steel, What is the Most Cost-Effective Metal Overall?

Steel is strong and cheap, but sometimes too heavy. This can lead to designs that are overbuilt or inefficient, especially when weight is a factor.

Aluminum alloys, particularly grades like 6061, often present the best overall cost-effectiveness when considering material price, excellent machinability, good strength-to-weight ratio, and corrosion resistance. Manufacturing processes like extrusion can further reduce costs.

While steel wins on raw strength per dollar for many applications, aluminum often comes out on top when you look at the bigger picture, especially for parts where weight matters or complex shapes are needed. I’ve guided many clients, including Alex with his robotics projects, towards aluminum when they need a balance of properties and good value.

The Appeal of Aluminum Alloys

Aluminum alloys like 6061-T6 are incredibly popular for a reason. It offers a good balance of strength, weldability, machinability, and corrosion resistance at a moderate price. It’s much lighter than steel, which is a huge advantage in transportation, robotics, and consumer electronics. While not as strong as high-strength steels in absolute terms, its strength-to-weight ratio is excellent. For many structural applications where mass needs to be minimized, aluminum is a fantastic choice. We machine a vast amount of 6061 aluminum at QuickCNCs. It’s relatively easy on our tools, which translates to faster cycle times and lower machining costs compared to tougher materials. Other alloys like 7075 offer much higher strength, approaching some steels, but they are more expensive and a bit harder to machine.

Cost Savings Through Manufacturing: Aluminum Extrusion

One area where aluminum really shines for cost-effectiveness is through processes like extrusion. Aluminum extrusion allows for the creation of complex custom shapes with consistent cross-sections. This can drastically reduce the amount of machining needed later. Think about complex profiles for enclosures, heat sinks, or structural frames. By designing the part as an extrusion, you can often eliminate multiple machining operations, welding, or assembly steps. I’ve seen this approach save clients significant amounts of money and reduce lead times. The initial tooling cost for an extrusion die can be a factor, but for medium to high-volume production, it’s often quickly offset by the savings in piece price and secondary operations.

Comparing Overall Project Costs

When evaluating cost-effectiveness, it’s important to look beyond just the raw material price per kilogram. You need to consider:

- Machining costs: Aluminum is generally faster and easier to machine than steel or exotic metals.

- Finishing costs: Aluminum naturally resists corrosion well, sometimes reducing the need for protective coatings.

- Assembly costs: Lighter parts can be easier to handle and assemble. Extrusion can reduce part count.

- Shipping costs: Lighter parts cost less to ship.

For many projects I’ve managed, even if the per-kilogram cost of aluminum was slightly higher than a basic steel, the total manufactured part cost ended up being lower due to these other factors.When Metal Isn’t the Only Answer, What Are Good Substitutes?

Sometimes, even the most cost-effective metals don’t meet all design needs. This might be due to weight, electrical properties, or extreme temperature requirements.

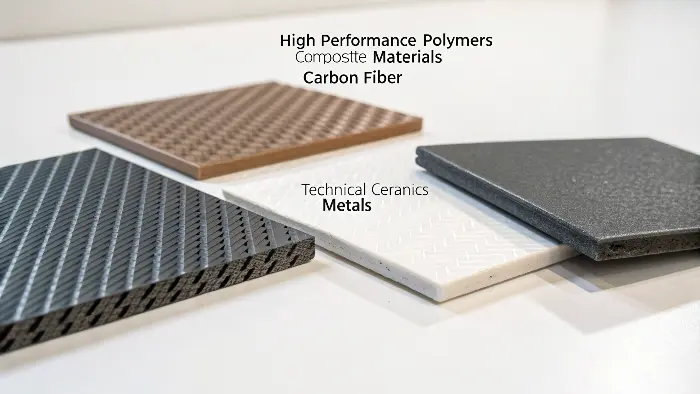

High-performance polymers, composites like carbon fiber, and technical ceramics can be excellent substitutes for metals, offering unique properties like exceptional strength-to-weight ratios, electrical insulation, or high-temperature stability, often with design flexibility.

There are times when stepping away from metals altogether is the best solution. I always encourage engineers to think broadly about material options. My insights show that for specific needs, non-metallic materials can outperform and even be more cost-effective than trying to force a metal into an unsuitable application.High-Performance Polymers and Composites

Don’t underestimate modern plastics! High-performance polymers like PEEK, Ultem, or even reinforced nylons can offer impressive mechanical properties, excellent chemical resistance, and are lightweight. For applications with complex geometries, injection molding these polymers can be very cost-effective in high volumes. Then you have composites, with carbon fiber reinforced polymers (CFRP) being a prime example. Carbon fiber offers incredible stiffness and strength at a very low weight, often exceeding the strength-to-weight ratio of even the best metals. I’ve seen it used to replace metal in aerospace, high-performance automotive parts, and robotics where minimizing inertia is critical. While raw carbon fiber can be expensive and manufacturing complex, for the right application, the weight savings and performance gains are unmatched. It also provides great design flexibility.

The World of Technical Ceramics

When you think of ceramics, you might picture dinner plates. But technical ceramics are a whole different game. Materials like alumina, zirconia, silicon carbide, sapphire, aluminum nitride, and boron nitride offer properties that metals simply can’t match. These include extreme hardness, high compressive strength, excellent wear resistance, high-temperature stability, and electrical insulation (or conductivity for some). I’ve seen ceramics used for wear components, cutting tools, insulators, and even in high-temperature environments where metals would fail. For example, if you need a part that is extremely hard and can withstand high temperatures, a ceramic might be a better and ultimately more cost-effective choice than an exotic refractory metal, despite potentially higher initial processing costs. They can be brittle, so design considerations are important, but for specific niches, they are unbeatable.

Weighing the Pros and Cons

Choosing a non-metal substitute requires careful evaluation: Material Type Key Advantages Potential Considerations Polymers (e.g., PEEK) Lightweight, chemical resistance, good machinability, can be molded Lower strength/stiffness than metals, temperature limits Composites (e.g., Carbon Fiber) Exceptional strength-to-weight, design flexibility, fatigue resistance Higher material/manufacturing cost, anisotropic Ceramics (e.g., Alumina) Extreme hardness, wear resistance, high-temp stability, electrical insulation Brittleness, specialized manufacturing Each of these alternatives brings unique benefits. The key is to match their strengths to your specific application needs where metals might fall short or be overly expensive for the required performance.

Can We Make Common Metals Stronger to Avoid Exotic Costs?

You need more strength, but upgrading to an exotic metal is too expensive. This common problem can stall projects or lead to over-engineered, costly designs.

Yes, various methods like heat treatment (quenching, tempering, annealing), cold working (strain hardening), and alloying can significantly increase the strength of common, less expensive metals, making them viable alternatives to pricier exotic materials.

Instead of always jumping to a more expensive base material, sometimes the smarter and more cost-effective route is to enhance the properties of a common metal. I’ve seen this strategy save clients a lot of money. It’s about unlocking the hidden potential within more affordable alloys.The Power of Heat Treatment

Heat treatment is one of the most common and effective ways to alter the mechanical properties of metals, especially steels and some aluminum alloys. Processes include:

- Annealing: Softens the metal, improves ductility and machinability, and relieves internal stresses.

- Normalizing: Refines grain structure in steel for improved strength and toughness.

- Hardening (Quenching): Involves heating steel to a high temperature and then cooling it rapidly (quenching) to make it very hard but also brittle.

- Tempering: A subsequent heating process after quenching, done at a lower temperature, to reduce brittleness and increase toughness while retaining much of the hardness.

I often work with clients to specify heat treatments for alloy steels like 4140 or 4340. A properly heat-treated 4140 can achieve impressive strength levels, making it suitable for demanding applications where an untreated, lower-grade steel would fail. This is often far cheaper than opting for a stainless steel or an exotic alloy purely for strength.Cold Working for Increased Strength

Cold working, also known as strain hardening, involves deforming a metal at a temperature below its recrystallization point. Processes like rolling, drawing, or even some forming operations can increase a material’s tensile strength and hardness. This happens because the plastic deformation introduces more dislocations into the metal’s crystal structure, which then impede further dislocation movement, making the material stronger. Think of bending a paperclip back and forth – it gets harder to bend at the point of deformation. While this increases strength, it usually reduces ductility. For some applications, sourcing cold-worked raw material or designing processes that induce cold work can be a way to achieve higher strength from a less expensive base metal.

Alloying: The Foundation of Strength

Alloying itself is a fundamental method for increasing the strength of metals. Pure metals are often relatively soft. Adding other elements (alloying elements) in specific quantities can dramatically change their properties. For example, carbon is the key alloying element that turns soft iron into strong steel. Chromium and nickel make stainless steel strong and corrosion-resistant. Aluminum alloys get their strength from additions of copper, silicon, magnesium, and zinc. When we choose an "alloy steel" or a "7000 series aluminum," we are already leveraging the power of alloying. Understanding how different alloying elements influence properties helps in selecting an existing, cost-effective alloy that can be further enhanced by processes like heat treatment. Sometimes, a slightly more expensive alloy with a better response to heat treatment can be more cost-effective overall than a cheaper alloy that can’t achieve the required strength.

How Can Smart Design and Sourcing Strategies Reduce Material Costs?

Material costs are high, and simply picking a cheaper metal isn’t always enough. This can leave engineers feeling stuck between performance and budget.

Strategic design optimization, early collaboration with manufacturing partners, smart material sourcing, and exploring cost-effective manufacturing processes like 3D printing or leveraging mold cost amortization can significantly reduce overall part costs without compromising essential performance.

As a manufacturing expert, I’ve learned that the material itself is only part of the cost equation. How you design your part, who you work with, and how you approach manufacturing can have a massive impact on the final price. These strategies are key to making strong parts more affordable.Early Design Collaboration for Cost-Effectiveness

One of the most impactful strategies I advocate is involving your design engineers and your manufacturing partner, like QuickCNCs, very early in the product development process. When we collaborate at the concept stage, we can often identify opportunities to:

- Optimize the design for manufacturability (DFM): Minor design changes can sometimes drastically reduce machining time or allow for a more cost-effective manufacturing method.

- Select more economical materials: We can discuss if a slightly less expensive material, perhaps combined with a specific heat treatment or design tweak, can meet the performance requirements.

- Explore alternative production methods: Perhaps part of the component can be cast or extruded, then finish-machined, saving material and time.

This early collaboration avoids costly redesigns later and ensures the design is inherently cost-effective from the start.Strategic Material Sourcing and Inventory Management

Beyond just picking a cheaper material, how you source it matters. This includes:

- Understanding market conditions: Material prices can fluctuate. Working with a knowledgeable supplier can help you navigate this.

- Efficient inventory management: For businesses, this means avoiding overstocking expensive materials while ensuring availability.

- Exploring alternative grades or near-equivalents: Sometimes, a slightly different but more readily available or less expensive grade can meet the needs.

My experience in global sourcing helps me find the right balance of cost, quality, and availability for my clients’ projects.Leveraging Cost-Effective Manufacturing Processes

Thinking beyond traditional machining can also unlock savings:

- 3D Printing (Additive Manufacturing): For complex geometries, prototypes, or small production runs, 3D printing with metal powders (like stainless steel or aluminum) or even high-strength polymers can be a very cost-effective alternative. It offers immense design freedom and minimizes material waste. I’ve used it for intricate parts that would be very expensive or impossible to machine conventionally.

- Aluminum Extrusion: As mentioned earlier, for parts with consistent profiles, extrusion can drastically cut down on machining.

- Near-Net Shape Forming: Processes like casting or forging get the part closer to its final shape before machining, reducing material waste and machining time.

Mold Cost Amortization and Cost Avoidance

For processes involving molds or dies (like injection molding, die casting, or extrusion), the upfront tooling cost can be significant. Some manufacturers, including us for certain projects, might offer services where mold costs can be amortized, or spread out, over a longer production run. This makes the initial investment less daunting. Furthermore, focusing on "cost avoidance" through smart design—optimizing material usage, reducing complexity where possible, and designing for efficient assembly—can lead to substantial long-term savings in the total cost of ownership. It’s about looking at the entire lifecycle cost, not just the initial piece price.

Conclusion

Finding cost-effective alternatives to exotic metals involves exploring high-strength steels, aluminum, non-metals, smart manufacturing, and design. These practical solutions deliver performance without breaking your project budget.