Struggling with lengthy setup times for CNC machining? These delays eat into profits and slow down production. Modular fixturing systems offer a fast, flexible solution.

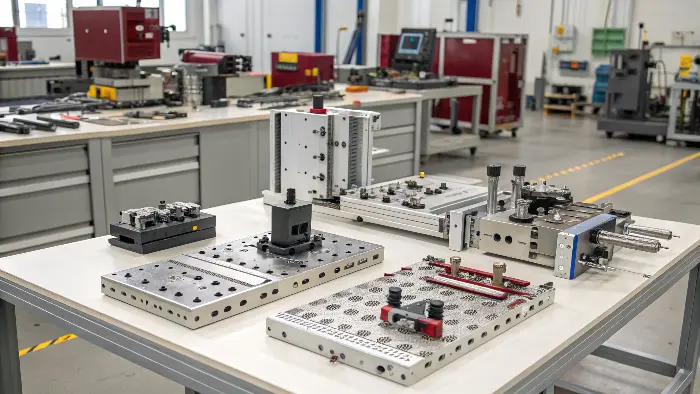

Modular fixturing systems are versatile workholding solutions. They use standardized components like base plates, clamps, and locators. You can quickly assemble and reconfigure them for various workpiece sizes and shapes, significantly boosting CNC machining efficiency.

Modular fixturing has really changed how I approach CNC setups in my own experience helping clients optimize their production through QuickCNCs. If you’re looking to cut down on that non-productive time and get more parts out the door, understanding these systems is key. Let’s explore how they can transform your workflow and why they are so valuable.

What Exactly Are Modular Fixturing Systems and How Do They Work?

Confused by how modular fixtures achieve such versatility? Complex setups can seem daunting and time-consuming. Understanding their core components makes it surprisingly simple and effective.

Modular fixturing systems use a grid-based base plate. You attach various standardized components like clamps, locators, and supports. This allows for rapid assembly and adjustment to securely hold diverse workpieces for CNC machining.

I remember when I first started working extensively with these systems over a decade ago. The "aha!" moment for me was realizing it’s like a high-precision, industrial-strength construction set for machinists. The core idea is straightforward: you start with a base plate that has a very precise pattern of holes or T-slots. Then, you have access to a whole catalog of interchangeable components designed to fit this base.

Key Components and Their Functions

Let’s break down what makes these systems so effective for holding parts securely and accurately:

- Base Plates: These are the foundation of any modular setup. They typically come in various standard sizes and are often made from hardened steel or high-quality aluminum. They feature either a grid of accurately machined and spaced tapped holes for bolting components or T-slots for flexible positioning. This precise grid is absolutely crucial for ensuring repeatability in your setups.

- Locating Elements: Think of components like precision dowel pins, V-blocks, locating pins, and fixed or adjustable stops. Their primary job is to position the workpiece accurately on the base plate and ensure it’s in the exact same spot every single time you load a new part. For high-tolerance work, the quality of these locators is paramount.

- Clamping Elements: These components are responsible for holding the workpiece firmly in place against the cutting forces. Common examples include toe clamps, strap clamps, edge clamps, and various push/pull style clamps. They need to provide sufficient holding force without distorting the workpiece, which is especially important for delicate or thin-walled parts.

- Supporting Elements: This group includes items like risers, support jacks, adjustable supports, and angle plates. They ensure the workpiece is stable, well-supported, and doesn’t vibrate or deflect under the machining forces. Proper support is critical for maintaining dimensional accuracy and achieving good surface finishes.

The real power and efficiency of these systems become apparent when you combine these elements. You can construct a reliable fixture for a completely new part in a matter of minutes or a few hours, a stark contrast to the days or even weeks it might take to design and build a dedicated, custom fixture. This rapid adaptability is a game-changer.What Are the Key Advantages of Using Modular Fixtures in CNC Operations?

Facing tight deadlines and constantly rising setup costs? Traditional, dedicated fixturing can be very slow to implement and expensive to produce for each new job. Modular systems offer significant, measurable time and cost savings.

The main advantages are greatly reduced setup times, increased flexibility for diverse parts, and substantially lower tooling costs. They also improve repeatability and allow for quicker changeovers, boosting overall CNC machine utilization and productivity.

When I guided one of my first clients at QuickCNCs to switch to using more modular systems in their CNC operations, the benefits were immediately clear and quite striking. It wasn’t just one single improvement; it was a combination of several positive factors that really made a difference to their bottom line and production speed.Tangible Benefits for Your Shop

Here’s a more detailed breakdown of why these systems are so impactful for any CNC machining environment: Advantage Description Impact on Operations Speed & Efficiency Drastically cuts down fixture design and assembly time. Quick changeovers between different jobs become standard practice, not an exception. Increased machine uptime, significantly faster lead times Flexibility Easily adapts to a wide range of different part geometries, sizes, and complexities. Ideal for high-mix, low-volume production runs. Handles a much wider variety of jobs with existing tools Cost Savings Reduces the need for expensive, single-purpose dedicated fixtures. Components are reusable across countless setups, spreading the cost. Lower tooling investment, much better return on investment Repeatability Precision-manufactured components ensure consistent workpiece positioning, which is crucial for maintaining tight tolerances and quality control. Improved part quality, considerably less scrap and rework Space Saving Components can be stored compactly in tool cabinets or carts, freeing up valuable shop floor space compared to bulky dedicated fixtures. More organized, safer, and efficient workspace Reduced Lead Time Fixtures can be assembled "just-in-time" as needed, eliminating delays waiting for custom fixtures to be designed and built. Faster time-to-market for new products or prototypes For engineers like Alex, who regularly deal with high-tolerance components, that enhanced repeatability is a massive win. Less time spent measuring, adjusting, and tweaking setups means more confidence in the final product quality and a smoother production flow. The ability to quickly iterate on prototype designs is another huge plus.

How Do You Choose the Right Modular Fixturing System for Your Needs?

Feeling overwhelmed by the sheer variety of modular fixturing options available on the market today? Choosing the wrong system or an inadequate one can unfortunately be a costly mistake in the long run. A few key considerations will guide you.

Consider your typical workpiece size, weight, and material, plus the required tolerances and machining forces. Also, evaluate the system’s component range, ease of use, compatibility with your CNC machines, and overall cost versus long-term benefits.

Selecting the right modular fixturing system is absolutely crucial; it’s not a decision to be taken lightly. It’s definitely not a one-size-fits-all situation. I always tell my clients at QuickCNCs to think very carefully about their specific application requirements first before looking at glossy brochures or supplier websites.Key Selection Criteria

Here are some important questions I ask myself and encourage my clients to consider:

- Workpiece Characteristics:

- What are the typical dimensions (length, width, height) and weight of the parts you machine most often? Larger, heavier parts will naturally demand more robust and larger-format systems with higher load capacities.

- What materials are you predominantly machining (e.g., aluminum, steel, titanium, plastics)? This influences the required clamping force, the potential for part deformation, and sometimes the choice of component materials to avoid issues like galvanic corrosion.

- What are the tightest tolerance requirements you need to achieve? Higher precision parts necessitate modular systems whose components are manufactured to tighter tolerances themselves.

- Machining Operations:

- What kind of cutting forces will be involved in your typical operations (e.g., heavy rough milling versus light finishing passes or drilling)? This dictates the overall rigidity needed from the fixturing system to prevent chatter and maintain accuracy.

- How many axes are you typically using on your CNC machines (3-axis, 4-axis, full 5-axis)? Some modular systems are specifically designed or better suited for complex multi-axis machining, offering better tool access and clearance.

- System Features & Compatibility:

- Grid System Type: Do you prefer a T-slot base plate or a tapped hole grid system? T-slots generally offer more continuous flexibility in positioning components, while tapped hole grids can provide very positive and repeatable locations.

- Component Range & Availability: Does the manufacturer offer a sufficiently wide and deep variety of clamps, locators, supports, and specialized elements to cover your current and anticipated future needs? Check for specialty items you might need.

- Ease of Use & Training: How intuitive is the system to assemble and reconfigure? How quickly can your machinists and setup personnel learn to use it effectively and confidently? Consider the availability of training resources from the supplier.

- Machine Compatibility: Ensure the base plates and overall system height are compatible with your existing CNC machines’ table sizes, T-slot spacing, and Z-axis travel limitations.

Thinking through these points systematically helps avoid investing in a system that’s either overkill for your needs (and thus too expensive) or insufficient to handle your work (leading to frustration and poor results). For an engineer like Alex, who rightly values precision and reliability, a system known for its high-accuracy components and robust construction would be at the top of the list.What Are Some Best Practices for Implementing Modular Fixturing Effectively?

Bought a modular system but you’re not quite seeing the impressive results you expected? Unfortunately, poor implementation or lack of proper integration can negate all the potential benefits. Following best practices ensures maximum return on your investment.

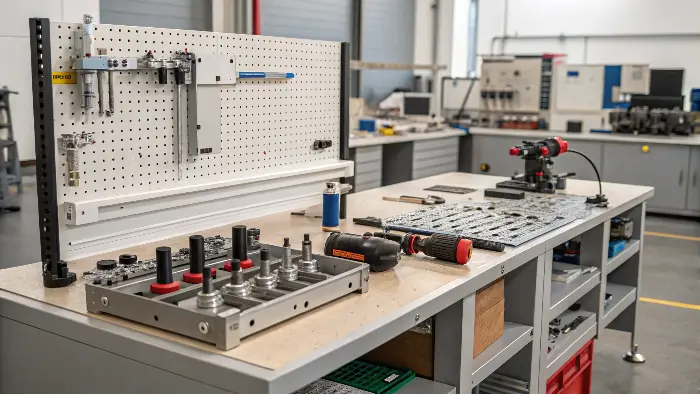

Invest in proper, thorough training for your team. Keep all components meticulously clean and well-organized. Document successful, proven setups for easy re-use. Regularly inspect components for any signs of wear or damage. Start with simpler parts to build confidence and expertise.

Getting the modular fixturing system delivered to your shop is just the first step. Using it well, consistently, and to its full potential is where the real magic happens and where the significant savings are realized. I’ve seen shops invest a good amount of money in these systems, only to let the expensive components gather dust in a corner because they weren’t fully integrated into the daily workflow.Maximizing Your Modular Fixturing Investment

Here’s what I’ve learned over the years, both in my own shop experience and from helping clients, that really works best:

- Workpiece Characteristics:

- Training is Absolutely Non-Negotiable: Your machinists, programmers, and setup personnel must understand the system’s capabilities, its limitations, and the principles behind building stable and accurate fixtures. Many suppliers offer excellent training courses, often hands-on. I always encourage dedicating time for this.

- Organization is Key to Efficiency: A well-organized storage system for all the modular components is vital. Think about custom shadow boards, clearly labeled drawers in dedicated tool carts, or visual storage systems. If components are hard to find, jumbled, or dirty, people will inevitably be less inclined to use them.

- Document Everything Methodically: When you create a successful and efficient setup for a recurring job, or even a complex one-off, document it thoroughly. Take clear photos or videos, note down the specific component part numbers used, and save the layout (CAD models of fixtures are even better if you have that capability). This saves an immense amount of time and guesswork for future runs.

- Maintenance Matters Greatly: Regularly clean all components, especially locating surfaces, threads, and moving parts. Inspect them for any signs of damage, nicks, burrs, or wear. Worn or damaged components will compromise the accuracy and rigidity of your setups, leading to rejected parts. Replace them as needed.

- Start Simple, Then Scale Up Complexity: Don’t try to tackle your most complex, tight-tolerance part on day one with the new system. Build experience and confidence by starting with simpler, less critical parts. This allows the team to learn the nuances of the system and helps identify any potential gaps in your component set before tackling high-stakes jobs.

For a detail-oriented engineer like Alex, documenting those proven setups for high-tolerance robotic parts would be absolutely critical to ensure part-to-part consistency across different batches and even different machine operators. This systematic approach pays off.Conclusion

Modular fixturing systems boost CNC efficiency, flexibility, and profitability. By understanding and implementing them well, you can transform your machining operations and save significant time and money.