Choosing the right manufacturing process for your aluminum parts can be a tough call. If you pick the wrong one, you could end up with sky-high costs, unacceptable lead times, or parts that just don’t meet your quality standards. This decision can make or break your project’s budget and timeline.

For aluminum parts, choose CNC machining for low-to-medium volumes, high-precision requirements, and complex designs, especially prototypes. Opt for die casting for high-volume production (10,000+ units) where a low cost-per-part is critical and justifies the significant initial tooling investment. Your decision hinges on volume, precision, and budget.

I’ve worked with both processes for years, and I’ve seen engineers struggle with this choice. Both CNC machining and die casting are excellent for creating aluminum components, but they serve very different purposes. I once had a client who started with CNC for their prototypes, and as their product took off, we helped them transition to die casting for mass production. Understanding when and how to make that switch is key. Let’s break down the details so you can choose with confidence.

What Are the Fundamental Differences Between CNC Machining and Die Casting?

You know that both CNC machining and die casting produce aluminum parts, but the actual methods can seem like a black box. This uncertainty can make you hesitate, worried you might overlook a critical detail that impacts your design, budget, or timeline. The core difference is actually very simple.

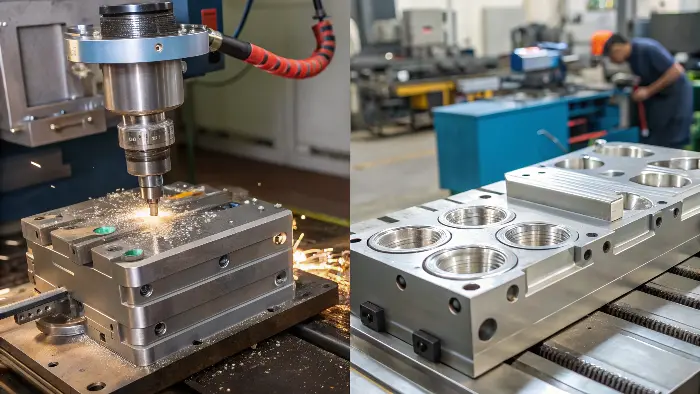

The fundamental difference is that CNC machining is a subtractive process that carves a part from a solid block of aluminum with cutting tools. In contrast, die casting is a forming process that injects molten aluminum into a custom steel mold (a die) under high pressure to create the part’s shape. One removes material, while the other shapes it.

Think of it like creating a sculpture. CNC machining is like a sculptor who starts with a solid block of marble and carefully chips away material to reveal the final statue. It’s precise, controlled, and can create incredibly fine details. Die casting, on the other hand, is like pouring liquid plaster into a mold to create a copy of a shape. It’s fast and perfect for making many identical copies.

This core difference—carving versus molding—is the source of all the other distinctions between the two processes. Because CNC machining starts with a solid block, or billet, it generates scrap material (chips). Die casting starts with molten metal, so it uses material more efficiently for the final part shape, though it requires runners and gates that are often remelted. The equipment is also completely different, which directly impacts tooling costs, lead times, and the types of geometries you can create.

Here’s a simple breakdown of their core mechanics:

| Feature | CNC Machining | Die Casting |

|---|---|---|

| Process Type | Subtractive (Material Removal) | Forming (Material Shaping) |

| Starting Material | Solid block or bar of aluminum | Molten aluminum ingot |

| Primary Tooling | Standard cutting tools (end mills, drills) | Custom-made steel die (mold) |

| Material Waste | Creates chips that are recycled | Creates runners/gates that are recycled |

Understanding this "carving vs. molding" principle is the first step to choosing the right path for your project.

When Does CNC Machining Make More Sense for Aluminum Parts?

You’ve designed a complex aluminum housing for a new robotic arm, and the tolerances are critical. You only need a dozen for testing and initial assembly. The thought of spending tens of thousands of dollars on a mold for such a small quantity is a non-starter. This is where CNC machining shines.

CNC machining is the ideal choice for aluminum parts when you need tight tolerances (e.g., ±0.01mm), complex geometries, and a superior surface finish. It is perfectly suited for prototypes, low-to-medium volume production (from 1 to around 10,000 pieces), and situations where you need parts fast without waiting for tooling to be made.

For an engineer like Alex, who works on high-tolerance components, CNC machining is often the default choice, especially during development. The reasons are very practical.

Key Scenarios for CNC Machining

First, prototyping and speed. With CNC, I can take a client’s CAD file and often have a physical aluminum part in their hands within a week. There is no tooling to create. This allows for rapid design iteration. If you test the part and find a flaw, you can simply update the CAD model and we can machine a new version immediately. This agility is impossible with die casting, where a single change to the die can be costly and time-consuming.

Second, precision and complexity. CNC machining can achieve tolerances and create features that are difficult or impossible with casting alone. We can easily machine sharp internal corners, perfectly flat mating surfaces, and threaded holes with extreme accuracy. The process starts with a solid block of wrought aluminum (like 6061 or 7075), which has a uniform internal structure and superior mechanical properties compared to cast aluminum. This means the final part is strong, reliable, and dimensionally stable, which is critical for high-performance applications in robotics or aerospace.

Finally, there’s no upfront tooling cost. The cost is almost entirely based on machine time and material. This makes it financially viable to produce just one part or a few hundred. You pay as you go, without a massive capital investment before you even see the first part.

When is Die Casting the Better Choice for Aluminum?

Your product is a success, and now you need to produce 50,000 aluminum enclosures per year. Machining each one individually would be incredibly slow and the per-part cost would make your product uncompetitive. You need a way to produce them quickly and cheaply at scale.

Die casting is the superior method for high-volume production runs, typically over 10,000 units, where the high initial investment in a steel die is justified by an extremely low cost-per-part. It is best for parts with stable designs and where some features like thin walls or complex external shapes are needed, even if tolerances are less critical than with CNC.

The decision to move to die casting is almost always driven by economics at scale. It represents a long-term commitment to a specific part design.

The High-Volume Advantage

The biggest factor is the cost trade-off. A die casting mold is a significant investment, often ranging from $10,000 to over $100,000 depending on its complexity and size. This is your barrier to entry. However, once that die is made, the cost to produce each part is incredibly low—often just a few dollars or even cents. The machine injects molten aluminum into the die and a new part is formed in seconds. This incredible production speed is what drives the unit cost down. For high volumes, the initial tooling cost gets spread across thousands of parts, making it the most cost-effective method by far.

Die casting also offers some unique design advantages. You can create very thin walls, which are difficult and expensive to achieve with CNC machining. It’s also excellent for producing parts with complex external curves and shapes. However, designers must account for die casting requirements, such as adding draft angles (slight tapers) to all walls so the part can be ejected from the mold. Features like undercuts or threads usually require secondary operations, which adds to the cost. The material properties are generally good, but not as strong or consistent as a part machined from a solid billet.

How Do Cost, Speed, and Quality Compare Directly?

You have the general idea, but now you need to present a clear business case to your manager or client. You need to lay out the facts side-by-side to justify your choice. A direct comparison of the most critical metrics—cost, speed, and quality—is essential for making a final, confident decision.

Directly compared, CNC has a low setup cost but higher part cost, making it ideal for low volumes. Die casting has a very high tooling cost but an extremely low part cost, making it ideal for high volumes. For speed, CNC is faster for initial parts, while die casting is massively faster in production. For quality, CNC offers superior precision and material integrity.

I always walk my clients through a table like this to make the choice clear. It removes the guesswork and focuses the decision on the factors that matter most to their project.

The Definitive Comparison Table

| Metric | CNC Machining | Die Casting |

|---|---|---|

| Tooling Cost | $0 (uses standard tools) | $10,000 – $100,000+ (custom die) |

| Part Cost (Low Vol) | Moderate to High | Prohibitively High (due to tooling) |

| Part Cost (High Vol) | Remains High | Very Low |

| Lead Time (First Part) | Fast (1-2 weeks) | Slow (8-16 weeks for tooling) |

| Lead Time (Production) | Slower (minutes/hours per part) | Very Fast (seconds per part) |

| Typical Tolerances | Very Tight (±0.01mm) | Moderate (±0.1mm), requires secondary machining for tighter specs |

| Surface Finish | Excellent, highly controllable | Good, but may show parting lines or ejector pin marks |

| Design Complexity | Excellent for internal features, sharp corners | Good for external shapes, thin walls; requires draft angles |

| Best Volume Range | 1 – 10,000 pieces | 10,000+ pieces |

As you can see, there is no single "winner." The processes are designed for different stages of a product’s lifecycle. CNC machining gives you flexibility, speed, and precision at the start. Die casting gives you scale and cost efficiency once your design is proven and demand is high. The right choice is the one that aligns with your project’s current needs.

Conclusion

Choosing between CNC machining and die casting for your aluminum parts isn’t about which process is better overall, but which is right for your specific job. For prototypes, complex parts, and low-volume runs where precision is key, CNC machining is your best bet. For mass production, die casting delivers unbeatable cost-per-part.