Grooving vs. Parting in CNC Machining: What Are the Key Differences and Applications?

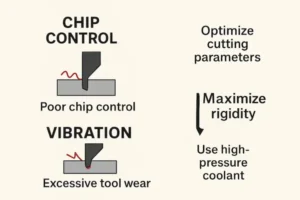

Struggling to choose the right tool for your CNC turning project? The line between grooving and parting can seem blurry, leading to wasted material, tool breakage, or poor surface finish. Making the wrong choice costs time and money. Simply put, parting (or parting-off) is the process of cutting a finished