Designing a medical implant with ceramic is tough. The material is strong but brittle, and the body’s safety is the top priority. One small manufacturing mistake can lead to a complete failure. So, how can you ensure your ceramic components are made perfectly every time?

Manufacturing ceramic components for medical implants involves three key stages. First is "green machining" the ceramic in its soft, pre-sintered state. Next, the part is fired in a furnace in a process called sintering, which hardens it. Finally, "hard machining" or diamond grinding is used to achieve the final shape, sub-micron tolerances, and an extremely smooth surface finish, all under strict ISO 13485 quality control standards.

Transition Paragraph:

I’ve seen many engineers like Alex, a colleague from Germany, wrestle with this process. He designs incredibly precise robotic components and knows that details matter. The world of medical ceramics is even more demanding. It’s not just about hitting a tolerance; it’s about ensuring a component can safely function inside a human body for decades. Understanding the manufacturing journey is the first step to mastering it. Let’s break down the essential steps and requirements to ensure your designs are successful.

Why Are Bioceramics the Go-To Material for Medical Implants?

Are you struggling to find a material that won’t corrode, wear out, or be rejected by the body? Metals have their limits, and polymers can lack strength. Choosing the wrong material for an implant isn’t just a design revision; it’s a critical risk to patient safety.

Bioceramics like Zirconia (ZrO2) and Alumina (Al2O3) are chosen for their superior biocompatibility, chemical inertness, and high wear resistance. Unlike metals, they do not corrode or release harmful ions into the body. Their extreme hardness and compressive strength make them ideal for long-term, load-bearing implants such as dental crowns and hip joint replacements, ensuring durability and patient safety.

Dive deeper Paragraph:

When I first started working with medical device clients, I was amazed by the properties of bioceramics. It’s one thing to machine a tough material for an industrial application, but it’s another thing entirely when you know it’s going inside a person. The reasons for choosing these materials are crystal clear once you look closer.

Unmatched Biocompatibility

The most important feature is biocompatibility. This simply means the material doesn’t cause a negative reaction from the human body. Metals can sometimes release ions, leading to allergic reactions or inflammation. Bioceramics, on the other hand, are chemically inert. The body basically ignores them, which is exactly what you want for a permanent implant. This prevents rejection and ensures the long-term health of the surrounding tissue.

Superior Mechanical Properties

Engineers like Alex are obsessed with mechanical performance. For implants like hip or knee joints, the components are under constant stress. Bioceramics really shine here. They are incredibly hard and have excellent wear resistance, meaning they don’t break down from friction over time. A polished ceramic-on-ceramic hip joint, for instance, produces far less wear debris than a metal-on-plastic one. This extends the life of the implant significantly.

| Property | Medical-Grade Zirconia | Medical-Grade Alumina | Titanium Alloy (Ti-6Al-4V) |

|---|---|---|---|

| Hardness (Vickers) | ~1200 HV | ~1500 HV | ~350 HV |

| Wear Resistance | Excellent | Excellent | Good |

| Biocompatibility | Excellent | Excellent | Good |

| Corrosion Risk | None | None | Low |

| Aesthetics | Tooth-colored | White | Greyish Metal |

This table shows just how big the gap is. The hardness of ceramics is more than three times that of titanium. For a part that needs to last 20 years or more, that difference is everything.

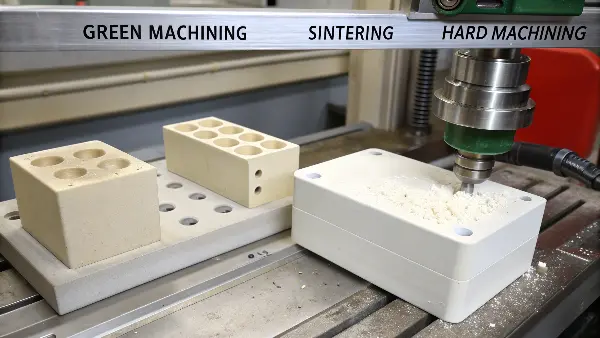

What Are the Critical Machining Stages for Medical Ceramic Components?

You have a perfect design for a ceramic implant, but you’re unsure how it goes from a block of material to a finished part. The manufacturing process can seem confusing, with terms like "green" and "hard" machining. A wrong move at any stage can ruin the expensive material.

The manufacturing process for medical ceramic components follows a strict sequence. It starts with "green machining" the compacted ceramic powder before it’s fully hardened. Then, the part undergoes sintering, a high-temperature firing process that densifies and shrinks it. Finally, precision diamond grinding, or "hard machining," is performed to achieve the final, ultra-precise dimensions and surface finish required for medical use.

Dive deeper Paragraph:

I remember a project involving a complex spinal fusion cage. The client was used to working with PEEK and titanium and was new to ceramics. We had to walk them through the entire process because, unlike metal, you can’t just cut it to its final size in one go. The multi-stage process is essential for success.

Step 1: Blank Preparation and Green Machining

Everything starts with a "green" ceramic blank. This is ceramic powder that has been pressed and mixed with a binder into a solid, chalk-like state. It’s soft enough to be machined using traditional CNC milling or turning techniques, but you have to be very careful. The material is fragile and can easily chip or crack. This is the stage where we create the near-net shape of the final component. The key here is to account for the material’s future shrinkage.

Step 2: Sintering

After green machining, the part goes into a high-temperature furnace. This is the sintering stage. The furnace heats the part to an extreme temperature, just below its melting point. During this process, the binder burns away, and the ceramic particles fuse, causing the part to densify and shrink significantly. This shrinkage can be up to 25% and must be calculated with extreme precision beforehand. This is what gives the ceramic its incredible hardness and strength.

Step 3: Hard Machining (Diamond Grinding)

Once sintered, the ceramic is incredibly hard—too hard for conventional cutting tools. This is where hard machining comes in. We use specialized CNC grinding machines with diamond-coated tools to slowly and carefully grind the material away. This process is used to achieve the final tight tolerances (often in the micron range) and the mirror-like surface finish required to reduce friction in joints. It’s a slow, high-precision process that requires constant cooling to prevent heat stress and micro-cracks. It’s where artistry meets engineering.

How Do You Achieve Sub-Micron Tolerances on Hard Ceramic Implants?

You’ve designed a component for a knee replacement that demands a tolerance of ±0.005mm. You know the sintered ceramic is harder than steel. How can any machine possibly achieve that level of precision without shattering the part? It feels like an impossible task.

Achieving sub-micron tolerances on hard ceramics requires specialized 5-axis CNC grinding machines, diamond-impregnated grinding wheels, and a controlled environment. The process uses high speeds and very low feed rates to carefully abrade the material. Continuous liquid cooling is critical to prevent thermal shock and micro-cracks, while in-process metrology systems provide real-time feedback to ensure every dimension is perfect.

Dive deeper Paragraph:

My friend Alex in Germany often deals with tolerances of ±0.01mm on metal parts, which is already very precise. When we talk about medical ceramics, we’re often aiming even tighter. Achieving this isn’t about brute force; it’s about control and finesse. We can’t "cut" the material in the traditional sense. We have to "grind" it.

The Right Equipment: CNC Grinding Centers

You can’t use a standard milling machine for this. You need a dedicated CNC grinding center. These machines are built for extreme rigidity to eliminate any vibration, which is the enemy of precision. They often use 5-axis capabilities to orient the part and the grinding wheel perfectly for complex geometries, like the ball head of a hip implant. The spindles on these machines rotate at incredibly high RPMs, which is necessary for effective grinding with diamond tools.

The Right Tools: Diamond Grinding Wheels

Because sintered ceramics like Zirconia are so hard, only one material is hard enough to shape them: diamond. The grinding wheels we use are not solid diamond but have fine diamond particles bonded to their surface. We use different grinding wheels with varying diamond grit sizes. We start with a coarser grit for rough material removal and then move to progressively finer grits for the final finishing and polishing stages. It’s like sanding wood, but on a microscopic and much, much harder scale.

The Right Process: Control and Cooling

The grinding process generates a lot of localized heat. If not managed, this heat can cause thermal shock, creating tiny, invisible micro-cracks that could lead to catastrophic failure of the implant later. To prevent this, we flood the part with a constant stream of high-pressure coolant. This not only controls the temperature but also washes away the removed ceramic dust. We also use very slow feed rates, removing only a few microns of material with each pass to minimize stress on the part. It’s a slow, methodical process that cannot be rushed.

What Quality Control and Sterilization Processes Are Absolutely Essential?

Your ceramic femoral head is machined to perfection, but how do you prove it’s free of defects and safe for implantation? A hidden micro-crack or surface contamination could have devastating consequences for a patient. Regular quality checks are not enough for medical devices.

Essential quality control for ceramic implants includes 100% visual inspection under magnification, Coordinate Measuring Machine (CMM) for dimensional verification, and non-destructive testing (NDT) like fluorescent dye penetrant to detect surface cracks. Following manufacturing, parts undergo a validated multi-stage cleaning and sterilization process, typically using gamma radiation or autoclaving, with full documentation to ensure traceability.

Dive deeper Paragraph:

In the world of medical components, "good enough" is never good enough. A component must be perfect, and you must be able to prove it. At QuickCNCs, our entire quality management system for medical parts is built around the ISO 13485 standard. This isn’t just a certificate on the wall; it dictates every step we take, from how we receive raw materials to how we package the final, sterilized product.

Rigorous Inspection at Every Step

Quality control isn’t just something we do at the end. We inspect parts after every major stage.

- After Green Machining: We check the near-net shape to ensure our shrinkage calculations are correct.

- After Sintering: We check for any warping or cracks that may have developed in the furnace.

- During and After Hard Grinding: This is the most intensive stage. We use CMM probes that touch the part to measure dimensions down to the micron. Laser scanners create a full 3D model of the part to compare against the original CAD file. Every single part is inspected, not just a sample from a batch.

Finding the Invisible Flaws

The biggest fear with ceramics is a micro-crack that you can’t see with the naked eye. To find these, we use a technique called Fluorescent Dye Penetrant Inspection (FPI). We apply a fluorescent dye to the part’s surface. The dye seeps into any tiny cracks. After we clean the surface, we put the part under a UV light, and any cracks will glow brightly, making them impossible to miss. Any part with even the tiniest indication is immediately scrapped. There are no second chances.

Cleaning and Sterilization

Finally, the part must be perfectly clean and sterile. It goes through an ultrasonic cleaning bath to remove any microscopic debris from the grinding process. Then, it’s packaged in a cleanroom environment in special multi-layer pouches. The final sterilization is often done using gamma radiation, which can penetrate the packaging to kill any microorganisms without damaging the ceramic part itself. Every step is documented to provide a complete history for that specific component.

Conclusion

Manufacturing ceramic medical implants requires a deep understanding of materials, specialized machinery, and strict quality control. From green machining to diamond grinding, every step is critical for patient safety.