Machining carbon fiber creates fine, sharp dust that can harm your lungs and skin. Ignoring this can lead to serious health issues and project delays. By following strict safety protocols, you can ensure the entire process is both safe and highly efficient.

Yes, carbon fiber machining is safe, but only with strict adherence to safety protocols. The primary risks come from the fine, abrasive, and conductive dust generated. To ensure safety, you must use comprehensive Personal Protective Equipment (PPE), implement high-efficiency dust extraction and ventilation systems, and adopt specific machining practices to control dust at its source.

Carbon fiber is an amazing material, but working with it demands respect. The unique challenges it presents aren’t just about getting the perfect cut or tolerance; they’re about protecting the people and the equipment involved in the process. I’ve seen shops take shortcuts, and the results are never good—ranging from irritated skin to damaged machinery. The good news is that all these risks are completely manageable. Investing in the right safety measures isn’t an expense; it’s a fundamental part of a successful and sustainable manufacturing operation. We are going to break down exactly what you need to do.

Is carbon fiber machining actually safe?

You want to leverage carbon fiber for its incredible strength-to-weight ratio, but you’re worried about the health risks you’ve heard about. This uncertainty can make you hesitate. Let me assure you, with the right knowledge and precautions, machining carbon fiber is a completely manageable and safe process.

Yes, machining carbon fiber is safe if, and only if, you manage the risks associated with its dust. The danger isn’t from the solid material but from the microscopic fibers released during cutting. These fibers are a respiratory hazard, a skin irritant, and can damage electronics. Safety is achieved through a three-pronged approach: containment, ventilation, and proper PPE.

The conversation around carbon fiber safety always comes back to the dust. Unlike wood or metal dust, carbon fiber dust is unique in its combination of hazards. It’s not just an airborne particle; it’s a collection of tiny, sharp, and conductive needles. In my early days, I learned this the hard way when a brand-new CNC machine controller mysteriously failed. When the technician opened it up, the circuit boards were covered in a fine black powder. That expensive lesson taught me that carbon fiber dust doesn’t just threaten people; it threatens the entire operation. It’s abrasive, so it wears down machine components like ball screws and linear guides. It’s also conductive, so it can short-circuit sensitive electronics. The most serious risk, of course, is to health. The body cannot easily break down these inhaled fibers, which can lead to chronic respiratory conditions. Understanding these multi-faceted risks is the first step toward building a truly safe machining environment.

Here is a breakdown of the primary risks and how to manage them:

| Risk Category | Specific Hazard | Key Mitigation Strategy |

|---|---|---|

| Health | Respiratory damage from inhaled fibers | HEPA-filtered dust extraction at the source; P3/N100 respirator |

| Severe skin irritation and dermatitis ("carbon rash") | Full-body disposable coveralls and nitrile gloves | |

| Eye irritation from airborne particles | Sealed safety goggles or a full-face shield | |

| Equipment | Short-circuiting of electronics due to conductive dust | Sealed machine enclosures; dedicated, high-power vacuum systems |

| Premature wear on mechanical parts (bearings, ways) | Wet machining; thorough and regular machine cleaning | |

| Workplace | Potential for dust explosion (in high concentrations) | Proper ventilation and dust collection to prevent accumulation |

| Slip hazards from accumulated dust on floors | Regular cleanup using certified HEPA vacuums (not compressed air) |

What Personal Protective Equipment (PPE) is essential for cutting carbon fiber?

You know PPE is necessary, but you’re not sure exactly what gear to use for carbon fiber. Using the wrong equipment, like a simple dust mask, can give you a false sense of security while leaving you exposed. Let’s clarify the essential, non-negotiable PPE that guarantees your protection.

The essential PPE for carbon fiber includes a P3/N100-rated respirator, sealed safety goggles, disposable full-body coveralls, and nitrile gloves. This combination creates a complete barrier. It prevents inhalation of microscopic fibers, protects eyes from high-velocity particles, and stops the sharp dust from embedding in your skin and causing severe irritation.

When setting up a new carbon fiber machining cell, the first thing we budget for is PPE. It is the last line of defense, but it’s the most personal one. Each piece of equipment serves a very specific purpose. The goal is to create a complete seal between the operator and the hazardous environment. You want to prevent any dust from being inhaled, touching the skin, or getting into the eyes. Some people think a simple paper mask and safety glasses are enough. They are absolutely not. I once saw an engineer walk through a work area for just a few minutes without proper gear. For the next week, he complained about an incredibly itchy rash on his neck and arms. The microscopic fibers had embedded in his skin, and they are extremely difficult to remove. This experience reinforces why we insist on full-body protection, even for short exposures. The gear might feel cumbersome at first, but it quickly becomes a habit, and it is the only way to work with this material safely day in and day out.

Here is a more detailed look at the gear and why each component is critical:

1. Respiratory Protection

This is the most critical piece of PPE. The fine dust from carbon fiber is a major respiratory hazard.

- What to Use: A half-mask or full-face respirator with P3 (in Europe) or N100 (in the US) rated particulate filters.

- Why it’s Crucial: These filters are certified to capture 99.97% of airborne particles. A simple surgical or N95 mask is not sufficient to block the finest and most dangerous fibers. A proper fit is also essential; always perform a seal check before entering the work area.

2. Skin Protection

Carbon fiber dust is like microscopic fiberglass, causing intense itching and dermatitis known as "carbon fiber rash."

- What to Use: Disposable, hooded coveralls (e.g., Tyvek suits) and nitrile gloves.

- Why it’s Crucial: The coveralls provide a full-body barrier. Cuffs should be taped at the wrists and ankles to prevent dust from getting inside. Nitrile gloves protect the hands and should be disposed of after use, as the fine dust can be impossible to wash off completely.

3. Eye and Face Protection

High-speed cutting operations can eject particles and sharp dust.

- What to Use: Sealed safety goggles are the minimum. A full-face shield worn over safety glasses offers the best protection.

- Why it’s Crucial: Goggles prevent particles from getting into your eyes from the sides, top, or bottom. A full-face shield adds another layer of protection for your entire face and can be a requirement when using certain tools or performing high-risk operations.

Do you really need a respirator when working with carbon fiber?

You see operators working with other materials who only wear a simple mask, if anything. This might make you wonder if a full respirator for carbon fiber is an overreaction. You might be tempted to cut corners to improve comfort or speed. Let me be clear about why this is a mistake.

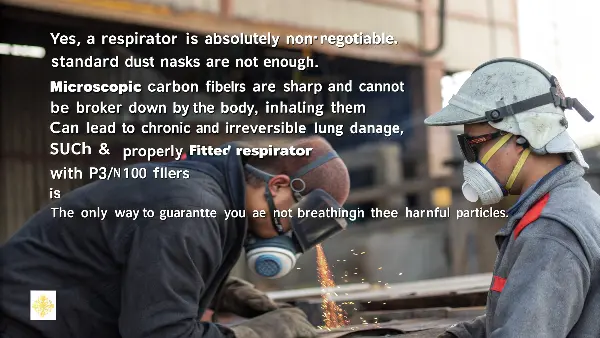

Yes, a respirator is absolutely non-negotiable. Standard dust masks are not enough. The microscopic carbon fibers are sharp and cannot be broken down by the body. Inhaling them can lead to chronic and irreversible lung damage, such as pulmonary fibrosis. A properly fitted respirator with P3/N100 filters is the only way to guarantee you are not breathing in these harmful particles.

There is no debate on this topic within the professional machining community. Using a respirator is not a suggestion; it’s a fundamental requirement. The danger from carbon fiber dust is invisible and cumulative. You won’t feel the damage after one day or one week, which gives a false sense of security. The harm builds up over months and years, and by the time symptoms appear, the damage is often permanent. I’ve spoken with safety professionals who have studied the long-term effects, and their message is always the same: protect the lungs above all else. Think of it like a welder’s helmet. Would you ever consider welding without eye protection? Of course not. The risk is immediate and obvious. The risk from carbon fiber dust is silent and delayed, which makes it even more dangerous because it’s easy to ignore. That’s why we enforce a strict "no respirator, no work" policy in our shops. It is the most important safety rule we have when machining composites.

To help you understand the gravity of this, let’s compare different types of respiratory protection and their effectiveness against carbon fiber dust:

| Type of Protection | Effectiveness Against Carbon Fiber Dust | Recommended Use |

|---|---|---|

| No Mask | Zero. Offers no protection. Extremely dangerous and should never be considered. | Never. |

| Surgical Mask | Very Low. Designed to stop droplets from the wearer, not to filter inhaled air. Does not seal to the face. | Not suitable for industrial use. Provides no real protection from fine dust. |

| N95 Dust Mask | Inadequate. While it filters 95% of certain particles, it may not seal well enough or filter the smallest fibers effectively. Not designed for repeated use in heavy dust environments. | Not recommended for carbon fiber. May be used for nuisance dusts, but not for this hazard. |

| Half-Mask Respirator (P3/N100) | Excellent. When fitted correctly, it creates a tight seal and filters over 99.97% of airborne particles. This is the industry standard for safe carbon fiber work. | Essential. This is the minimum requirement for any carbon fiber machining task. |

| Full-Face Respirator (P3/N100) | Excellent. Provides the same high-level respiratory protection as a half-mask, plus integrated eye and face protection. | Highly Recommended. It offers a superior seal and all-in-one protection. |

| Powered Air-Purifying Respirator (PAPR) | Superior. A battery-powered fan pushes filtered air into a hood or helmet. Creates positive pressure, making breathing easier and preventing leaks. | Best Practice. Ideal for long-duration work or for individuals who have trouble with traditional respirator seals. |

How can you safely CNC machine carbon fiber parts?

You have your PPE sorted, but you know that personal gear is just the last line of defense. You are now wondering what you need to do at the machine itself. How do you stop the dangerous dust from spreading in the first place? Let us walk you through the key processes.

Safe CNC machining of carbon fiber relies on two core principles: dust capture and process optimization. You must use a powerful, HEPA-filtered dust extraction system that captures dust directly at the cutting tool. Additionally, using wet machining techniques and specialized, sharp tooling minimizes dust creation, ensuring a cleaner, safer, and more efficient operation.

When we set up a machine for a carbon fiber job, our strategy is always to control the dust at its source. We don’t want it to ever become airborne and travel around the shop. The most effective way to do this is with a high-volume vacuum system. The suction nozzle must be positioned as close to the cutting edge as possible. I’ve seen setups where the vacuum hose is just placed generally inside the machine enclosure, and that is not good enough. You need to capture the dust the split second it’s created. Another highly effective method is wet machining. By applying a constant flow of coolant to the cutting area, the dust is immediately trapped in the liquid. It turns from a dangerous airborne powder into a manageable slurry that can be filtered out of the coolant system. This not only controls the dust but also keeps the tool cool, which extends its life and improves the surface finish. Combining both methods—wet machining with powerful extraction—is the gold standard for high-volume carbon fiber production.

Here’s a practical checklist for setting up your CNC process safely:

1. Containment and Extraction

- Full Machine Enclosure: Use a CNC machine with a fully enclosed work area. This acts as the first barrier, keeping dust and coolant splash contained.

- High-Power Dust Collector: Invest in an industrial vacuum system with a high CFM (cubic feet per minute) rating. The system must be equipped with a HEPA filter to ensure that microscopic particles are not recirculated back into the shop air.

- Source Capture: Position the vacuum nozzle right next to the cutting tool. A "vacuum shoe" that fits around the spindle is an excellent solution for this.

2. Machining Process

- Wet Machining: Whenever possible, use a flood coolant system. The fluid traps dust, cools the workpiece and tool, and helps produce a better finish. The coolant must have a filtration system capable of removing the abrasive carbon sludge.

- Optimized Speeds and Feeds: Use high spindle speeds and fast feed rates. This helps to create larger chips rather than fine, powdery dust. This requires a rigid machine and proper tool holding.

- Tool Selection: Use extremely sharp, specialized cutters designed for composites. Polycrystalline Diamond (PCD) tools are expensive but offer the best performance and lifespan, producing cleaner cuts and less dust. Dull tools will rub and burn the material, creating more fine dust and a poor-quality part.

3. Cleanup and Maintenance

- No Compressed Air: Never use compressed air to clean machines or parts. This will send clouds of dangerous dust into the air.

- Use HEPA Vacuums: Clean all surfaces—the machine, the floor, the part—with a certified HEPA-filtered vacuum.

- Wipe Down Surfaces: After vacuuming, wipe down surfaces with a damp cloth to capture any remaining dust.

- Regular Coolant Maintenance: If wet machining, regularly clean and filter your coolant system to remove the abrasive carbon sludge, which can damage pumps and other components.

Conclusion

In summary, safe carbon fiber machining is entirely achievable. It depends on consistently using the right PPE, effective dust control at the source, and following proper cleanup procedures.