Choosing the wrong composite can ruin your project’s budget and performance. A material that’s too brittle could fail, while one that’s too heavy negates your design goals. Understanding the key differences between carbon fiber and fiberglass ensures you make the right choice.

The best choice depends on your needs. Carbon fiber offers a superior strength-to-weight ratio and stiffness, making it ideal for high-performance applications like aerospace and racing. Fiberglass is more affordable, flexible, and impact-resistant, so it’s widely used in boats and building materials. Your budget and performance requirements will ultimately guide your decision.

I’ve worked on many projects using both materials, from high-stakes aerospace components to durable industrial parts. Engineers often come to me asking for a detailed breakdown to help them decide. It’s a common challenge, but it gets easier when you break it down into a few key areas. So, let’s dive into the details that matter most for your design, starting with the fundamental properties of each material.

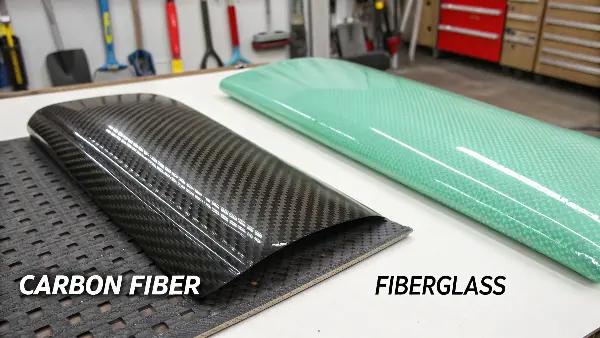

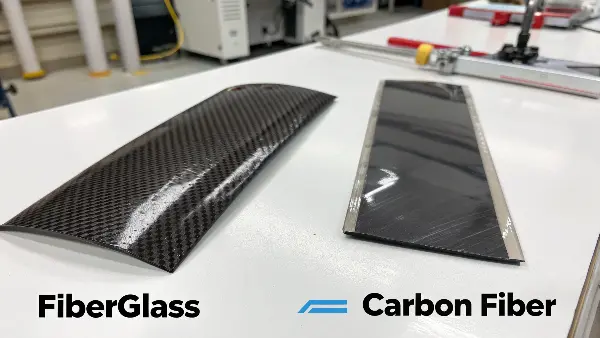

What are the properties of fiberglass vs carbon fiber?

Technical spec sheets can be confusing and don’t always tell the whole story. Picking a material based on one property, like tensile strength, without considering stiffness or durability can lead to unexpected failures down the line. Let’s compare the essential properties of both materials side-by-side.

Carbon fiber is significantly stronger, stiffer, and lighter than fiberglass. It has a much higher tensile strength and modulus of elasticity. Fiberglass, on the other hand, is more flexible and has better impact resistance. It can bend and absorb energy without shattering as easily as some carbon fiber composites might under direct impact.

When an engineer like Alex from Germany comes to me for a project, the first thing we discuss is the performance requirements. The choice between these two materials almost always starts with a deep look at their physical and mechanical properties. They behave very differently under stress, and that behavior defines where they can be used effectively. Let’s break it down further.

Strength-to-Weight Ratio

This is perhaps the most famous characteristic of carbon fiber. It measures a material’s strength in relation to its density. Carbon fiber is the clear champion here. For the same weight, a carbon fiber part can be many times stronger and stiffer than a fiberglass one. I remember a project for a robotics company where we were designing a long-reach robotic arm. Using steel or even aluminum would have made the arm too heavy to move quickly and accurately. We switched to carbon fiber tubes. The result was a lightweight, rigid arm that met all the performance specs. Fiberglass would have been too heavy and flexible for that level of precision.

Stiffness (Elastic Modulus)

Stiffness measures a material’s resistance to bending or flexing. A high elastic modulus means the material is very rigid. Carbon fiber has an exceptionally high modulus, making it perfect for applications where you cannot tolerate any flex. Think about an aircraft wing or the chassis of a Formula 1 car. They need to be incredibly rigid to maintain their shape under extreme forces. Fiberglass is much more flexible. This isn’t always a bad thing. For a product like a diving board or a fishing rod, you want that flexibility to store and release energy.

Durability and Composition

Durability is a broad term, but here I’m mainly talking about toughness and impact resistance. This is where fiberglass has an advantage. It can withstand impacts better than carbon fiber without fracturing. Carbon fiber, for all its tensile strength, can be quite brittle. A sharp, direct impact can cause it to crack or shatter. I’ve seen this in drone prototypes where hard landings shattered carbon fiber frames. We often recommend a fiberglass or a composite blend for applications that expect lots of bumps and shocks.

Here is a simple table to put these properties into perspective:

| Property | Carbon Fiber | Fiberglass | Key Takeaway for Engineers |

|---|---|---|---|

| Tensile Strength | Very High (e.g., 3.5 GPa) | High (e.g., 1.7 GPa) | Carbon fiber handles pulling forces much better. |

| Stiffness (Modulus) | Very High (e.g., 230 GPa) | Low (e.g., 76 GPa) | Choose carbon fiber for rigidity; fiberglass for flexibility. |

| Density | Very Low (e.g., 1.6 g/cm³) | Low (e.g., 2.6 g/cm³) | Carbon fiber offers significant weight savings over fiberglass. |

| Impact Resistance | Fair to Poor (can be brittle) | Good to Excellent (tough and durable) | Fiberglass is better for parts that might get hit. |

| Fatigue Resistance | Excellent | Good | Carbon fiber withstands repeated stress cycles better. |

Is fiberglass more expensive than carbon fiber?

Your project likely has a strict budget. I’ve seen promising designs get stuck in development because the chosen material was just too expensive for production. Choosing a high-performance material you can’t afford can stall the entire project. Understanding the cost difference is critical for planning and success.

No, fiberglass is not more expensive than carbon fiber. In fact, it is significantly cheaper. The raw materials and manufacturing process for fiberglass are much less energy-intensive and complex. This makes fiberglass a highly cost-effective choice for a huge range of applications where budget is a primary concern.

Cost is often the deciding factor that pushes a project toward one material or the other. While an engineer’s mind focuses on performance, the procurement manager’s mind focuses on the bottom line. I work with both sides, so I am always balancing these two needs. The price difference between carbon fiber and fiberglass is not small; it’s substantial, and it comes from a few key areas.

The Source of the Cost

The journey of these materials from raw ingredients to a finished product explains the price gap.

- Raw Materials: Fiberglass starts with simple, abundant materials like sand (silica). The process of melting these ingredients and drawing them into fine fibers is well-established and efficient. Carbon fiber, on the other hand, typically starts from a polymer called polyacrylonitrile (PAN). PAN is a more expensive raw material to produce than glass.

- Manufacturing Energy: The process to turn PAN into carbon fiber is extremely energy-intensive. It involves heating the fibers to very high temperatures (up to 3000°C) in a special furnace without oxygen. This carbonization process is what gives the fibers their incredible strength, but it consumes a massive amount of energy and requires precise control, driving up the cost. The manufacturing of fiberglass happens at much lower temperatures and is a more straightforward process.

Is carbon fiber the most expensive material?

This is a question I get a lot, especially from people new to advanced materials. While carbon fiber is expensive compared to fiberglass or metals like steel and aluminum, it’s not the most expensive engineering material out there. Not by a long shot. The world of advanced materials is vast. For example, some specialty composites, like carbon fiber reinforced with high-performance thermoplastics like PEEK, can be much more costly. And when you look at high-temperature metals, materials like nickel-based superalloys (Inconel) or certain grades of titanium are far more expensive per kilogram.

Here’s a rough comparison to give you an idea of the relative material costs:

| Material | Relative Cost per kg | Main Reason for Cost |

|---|---|---|

| Mild Steel | $ | Abundant raw materials, simple production. |

| Fiberglass | $$ | Inexpensive raw materials, efficient manufacturing. |

| 6061 Aluminum | $$ | More energy-intensive than steel to process. |

| Standard Carbon Fiber | $$$$ | Expensive precursor (PAN) and high-energy processing. |

| Aerospace Grade Titanium | $$$$$ | Difficult to mine, refine, and machine. |

| High-Modulus Carbon Fiber | $$$$$+ | Even more specialized and energy-intensive manufacturing. |

So, while carbon fiber is a premium material, its cost is often justified by performance gains you can’t get anywhere else.

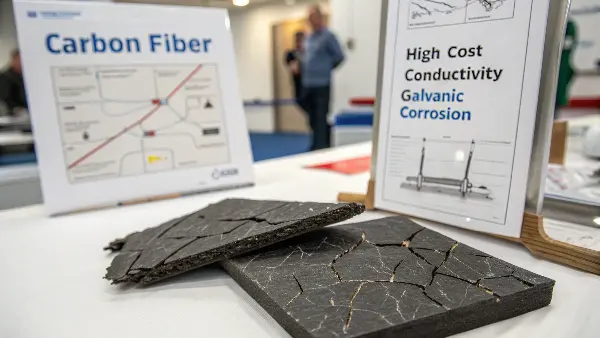

What are the disadvantages of carbon fiber?

Carbon fiber seems like a super-material, and in many ways it is. But it is not perfect. Overlooking its weaknesses can lead to expensive redesigns or even catastrophic failures. You might not consider its brittleness or electrical properties until it’s too late. Let’s look at the practical downsides you must consider.

The main disadvantages of carbon fiber are its high cost, its brittleness on sharp impact, and its electrical conductivity. It can shatter rather than bend, which is a risk in some applications. Its conductivity can cause issues with electronics if not properly insulated. It can also cause galvanic corrosion when touching certain metals.

Whenever I recommend carbon fiber for a part, I make sure to discuss its limitations. Every material has trade-offs, and being aware of them is just as important as knowing the benefits. Ignoring these can be a costly mistake. An engineer needs to design around these weaknesses to build a safe and reliable product.

Brittleness and Failure Mode

While carbon fiber has amazing tensile strength, it behaves differently from metal when it fails. Metals will typically bend, deform, and "yield" before they break, giving you a visual warning. Carbon fiber, however, is a brittle material. Under a sharp, localized impact, it doesn’t bend; it can fracture or shatter suddenly. One of my clients was developing a high-end camera tripod. The initial carbon fiber prototype was incredibly light and stable. But during testing, a user accidentally knocked it over, and one of the legs cracked cleanly in two. A similar aluminum leg would have likely just bent or dented. We had to adjust the design by reinforcing the joints to better protect against this kind of impact. This brittle nature is a critical safety consideration in applications where failure must be predictable.

Electrical Conductivity

This is a double-edged sword. Unlike fiberglass, which is an excellent electrical insulator, carbon fiber is conductive. This can be a benefit if you need to shield sensitive electronics from electromagnetic interference (EMI). The carbon fiber body can act as a Faraday cage. However, it can be a major problem if your design has electrical circuits running nearby. If a carbon fiber part accidentally touches a live circuit, it can cause a short. I’ve had to help engineers add insulating layers, often a thin layer of fiberglass, between the carbon fiber structure and the electronic components to prevent these issues.

Galvanic Corrosion

This is a technical detail that is extremely important for mechanical engineers like Alex to understand. When two different metals are in contact in the presence of an electrolyte (like salt water or even just moisture in the air), they can form a galvanic cell, and one metal will corrode the other. Carbon fiber is very noble (like a precious metal), so when it directly touches a more active metal like aluminum or steel, it will accelerate the corrosion of that metal. I have seen aluminum fasteners completely corroded away where they were bolted directly to a carbon fiber plate in a marine environment. The solution is to use a non-conductive barrier, like a fiberglass washer or a special coating, to isolate the two materials. Or, you can use more compatible fasteners like titanium, but that adds even more cost.

Where should you use carbon fiber instead of fiberglass?

You know the properties and the costs, but you’re still not sure which material fits your specific application. Making the wrong choice means you either over-engineer and over-spend with carbon fiber, or you under-engineer with fiberglass and risk failure. Let’s look at clear examples to guide your decision.

You should use carbon fiber when performance is the absolute priority and cost is a secondary concern. This includes applications needing the highest possible strength-to-weight ratio and stiffness. Think of aerospace components, high-performance race cars, professional sporting equipment like bicycles, and precision robotics.

After we’ve discussed properties, cost, and potential problems, the final question is always: "So which one do I use for my part?" The answer lies in defining what success looks like for your project. Is it winning a race, saving fuel on an airplane, or just building a durable product that thousands of people can afford? The mission defines the material.

When to Choose Carbon Fiber

The decision to use carbon fiber is almost always driven by a need for ultimate performance where weight and stiffness are critical.

- Aerospace and Defense: This is the classic use case. Every kilogram of weight saved on an aircraft means more payload capacity or better fuel efficiency. I’ve sourced CNC-machined molds for parts like winglets, fuselage panels, and drone structures. For these applications, there is no substitute for carbon fiber’s strength-to-weight ratio. The high cost is easily justified by the lifetime operational savings.

- Motorsports and High-Performance Automotive: In racing, stiffness and low weight mean faster lap times. A rigid chassis provides better handling and responsiveness. Lightweight body panels improve acceleration and braking. Fiberglass is simply too heavy and flexible to compete at this level.

- High-End Sporting Goods: Think of a professional cyclist’s bike frame, a high-performance tennis racket, or the shaft of a premium hockey stick. In each case, the material’s stiffness allows for efficient energy transfer (from the pedal to the wheel, from the arm to the ball), and its low weight reduces athlete fatigue.

- Precision Robotics and Automation: As I mentioned with the robotic arm project, when you need a structure to be very long, very stiff, and move very quickly without flexing or vibrating, carbon fiber is the ideal choice.

When to Choose Fiberglass

Fiberglass is the workhorse of the composites world. It’s the practical, reliable, and affordable choice for an enormous range of products.

- Marine Industry: The vast majority of boat hulls and decks are made from fiberglass. It is highly resistant to water, can take the impact from waves, and is affordable enough to build large structures. A carbon fiber boat would be incredibly light and fast, but also prohibitively expensive for most consumers.

- Construction: Fiberglass is used everywhere in construction. It’s used for insulation panels, roofing materials, prefabricated bathroom units, and structural beams. Its properties as an insulator (both thermal and electrical), its corrosion resistance, and its low cost make it perfect for these applications.

- Consumer and Industrial Products: From a simple water slide to a complex chemical storage tank, fiberglass is the go-to material. It can be easily molded into complex shapes, it’s durable, and it keeps the final product affordable.

Here’s a quick-reference table to help you decide:

| Application Area | Choose Carbon Fiber If… | Choose Fiberglass If… |

|---|---|---|

| Vehicle Body | …it’s for a race car needing maximum stiffness. | …it’s for a standard car, truck, or boat hull. |

| Structural Support | …you need maximum rigidity with minimum weight (e.g., aircraft wing spar). | …you need good strength and durability on a budget (e.g., building beam). |

| Sporting Goods | …it’s for professional gear where performance is everything. | …it’s for recreational or entry-level equipment. |

| Protective Casing | …it needs to be extremely lightweight and rigid (e.g., high-end instrument case). | …it needs good impact resistance and low cost (e.g., tool-box). |

Conclusion

Choosing between carbon fiber and fiberglass means balancing performance needs with your budget. Carbon fiber offers elite strength for demanding applications, while fiberglass provides impressive versatility and value for everyday use.