Choosing the wrong stainless steel can lead to catastrophic part failure from corrosion, wasting both time and money. Imagine your precisely machined component rusting away because it was exposed to salt or chemicals. Understanding the simple yet critical difference between 304 and 316 stainless steel is the key to preventing this.

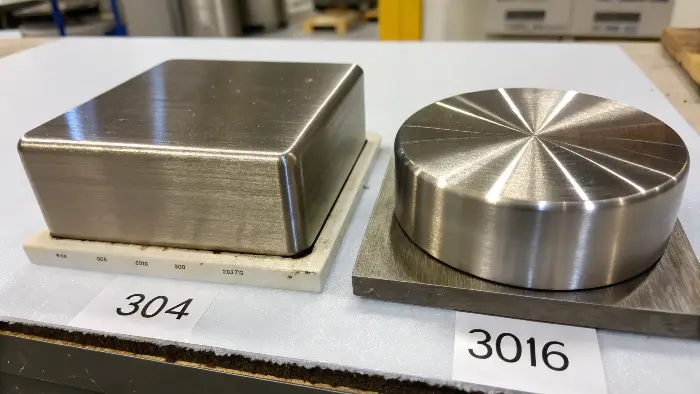

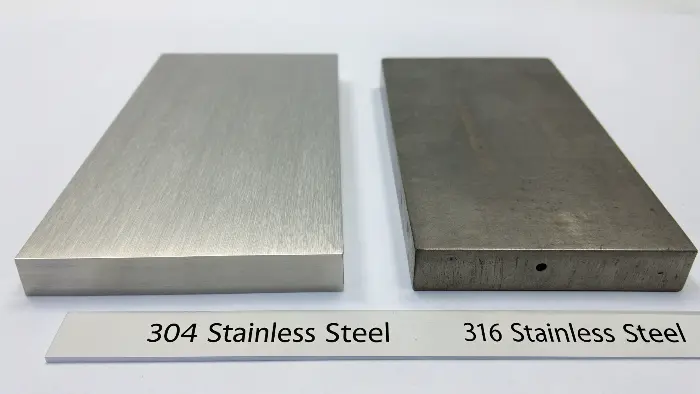

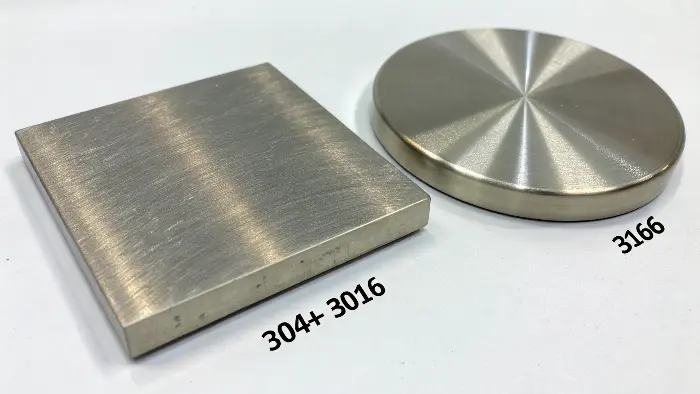

The main difference between 304 and 316 stainless steel is that 316 contains molybdenum. This addition gives 316 superior corrosion resistance, especially against chlorides found in saltwater and chemical solutions. While 304 is excellent for general use, 316 is the safer choice for parts exposed to harsh environments.

This simple difference in chemistry—the addition of one element—creates a big difference in performance and cost. But knowing this is just the start. To make the right call for your project, you need to understand how this plays out in the real world. Let’s dive deeper into the practical questions engineers like you ask every day.

Which is better 304 or 316 stainless steel?

Engineers often ask me for "the best" material, but this question can be a trap. Choosing a material because it seems "better" overall can lead to over-engineering and spending money on properties you don’t need. The real answer depends entirely on your project’s specific environment and budget.

Neither grade is universally "better." 316 stainless steel is better for applications requiring superior corrosion resistance, particularly in marine or chemical environments. 304 stainless steel is the better choice for general-purpose applications where cost is a primary concern, as it offers excellent protection in most normal conditions. The best choice is the one that fits the job.

The decision between 304 and 316 is one of the most common choices I see engineers make. I once worked with a client, let’s call him Alex, who was designing components for a robotic system. He initially specified 316 for everything, thinking it was the "safest" option. After we discussed the robot’s operating environment—a clean, indoor factory—we realized 304 was more than sufficient for 90% of the parts. This simple change saved him nearly 20% on his material costs without sacrificing any performance. This is a perfect example of how understanding the specific strengths of each material leads to a smarter, more economical design. The "better" material is the one that does the job perfectly without adding unnecessary cost.

A Tale of Two Steels

Think of 304 as the reliable workhorse of the stainless steel world. It’s the most widely used stainless steel for a reason. It offers fantastic resistance to corrosion from things like atmospheric conditions, most organic and inorganic acids, and food products. It’s strong, easy to form, and easy to weld. For most applications, from kitchen sinks to architectural paneling and general machine frames, 304 is the perfect choice.

316, on the other hand, is the specialist. It takes all the good qualities of 304 and adds an extra layer of defense. That defense comes from molybdenum. This element makes 316 highly resistant to pitting and crevice corrosion caused by chlorides. Chlorides are found in saltwater, de-icing salts, and many industrial chemicals. If your part is going on a boat, near the ocean, or inside a chemical processing plant, 316 is not just better—it’s essential.

| Feature | Grade 304 Stainless Steel | Grade 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent for general purposes | Superior, especially against chlorides |

| Cost | Lower (Baseline) | Higher (Typically 25-35% more) |

| Common Use | Kitchen equipment, architectural trim | Marine hardware, chemical tanks |

| Key Alloying Element | 18% Chromium, 8% Nickel | 16% Cr, 10% Ni, 2% Molybdenum |

Ultimately, the choice is a technical and financial trade-off. You are balancing the risk of corrosion against the cost of the material.

Why is 316 more expensive than 304?

You’ve received a quote for your parts and noticed that specifying 316 stainless steel makes the price jump. It’s natural to wonder if that extra cost is really worth it. Not understanding this difference can lead you to either cut corners or overspend on a feature you simply don’t need.

316 stainless steel is more expensive than 304 because its alloy contains molybdenum (typically 2-3%) and a higher percentage of nickel. Both molybdenum and nickel are valuable commodity metals with their own market prices. The cost of adding these elements during steel production is passed on, making 316 a premium material.

When you choose 316 over 304, you are essentially paying for an insurance policy against a specific type of corrosion. The price difference isn’t arbitrary; it’s directly tied to the raw materials that give 316 its special powers. I always tell my clients to think of it this way: the extra cost is an investment in the part’s longevity and reliability in a harsh environment.

Breaking Down the Cost

The two main drivers behind the higher price of 316 are its ingredients: molybdenum and nickel.

-

Molybdenum (The Magic Ingredient): This is the single biggest reason for the price difference. Molybdenum is a refractory metal that is not as common as iron or chromium. Its primary function in stainless steel is to significantly enhance resistance to chloride corrosion. Because it is a strategic and relatively expensive metal, adding even a small amount (2-3%) to the steel alloy has a direct and noticeable impact on the final cost.

-

Higher Nickel Content: Austenitic stainless steels like 304 and 316 rely on nickel for their formability, weldability, and overall toughness. Grade 316 typically contains more nickel than 304 (around 10% vs. 8%). Nickel is a major industrial commodity, and its price can be volatile. This higher nickel content further contributes to the premium price of 316.

| Element | Grade 304 (Typical %) | Grade 316 (Typical %) | Impact on Cost |

|---|---|---|---|

| Chromium | 18% | 16% | A key cost, but similar levels |

| Nickel | 8% | 10% | Higher content increases 316 cost |

| Molybdenum | 0% | 2% | Primary driver of cost difference |

I once had a project for a client making parts for a desalination plant. He was tempted to use 304 to reduce the initial cost. I showed him the material composition and explained that the molybdenum in 316 was specifically there to fight the high-salt environment. Choosing 304 would have guaranteed failure within a year. In this case, the higher cost of 316 wasn’t just a preference; it was a requirement for the part to function at all.

Is 304 or 316 stainless steel better for food?

When you’re designing equipment for the food and beverage industry, material choice is critical. There are strict rules for safety and hygiene. Using the wrong material can lead to food contamination, corrosion from cleaning agents, and a failure to meet important health regulations.

Both 304 and 316 stainless steel are considered "food-grade" and are safe for contact with food. 304 is the most common choice and is sufficient for most applications like countertops and utensils. However, 316 is the better choice for processing foods with high salt content (like brines) or high acidity (like tomato sauce), as it resists corrosion from these substances more effectively.

The term "food-grade" means the material is durable, non-corrosive, and easy to clean, ensuring it won’t leach harmful chemicals into the food. Both 304 and 316 meet this standard, but the specific food product and cleaning process will determine which one is the smarter choice for long-term reliability.

The Right Grade for the Right Food

For most everyday food contact, 304 is the king. It’s used for everything from mixing bowls and cutlery to large storage tanks for milk and beer. Its surface is non-porous, which prevents bacteria from hiding, and it doesn’t react with most foods. It provides the perfect balance of performance and cost for a huge range of applications.

You need to upgrade to 316 when the environment becomes more aggressive. Here are the key situations where 316 is the superior choice:

- High Salt Content: If the equipment will be in constant contact with salt, 316 is a must. This includes machinery for curing meats, processing pickles, or handling any food stored in a brine. The chloride in salt will attack and pit 304 over time, but 316’s molybdenum content protects it.

- High Acidity: While 304 can handle mild acids, highly acidic products like tomato paste, citrus juices, and vinegar can be a problem over the long term. 316 offers better resistance to these acids, ensuring the equipment remains pristine and doesn’t affect the food’s taste.

- Harsh Cleaning Protocols: Industrial food plants use powerful chemical sanitizers to ensure hygiene. These cleaners can be very corrosive. 316 holds up much better against these repeated chemical cleanings.

It’s also worth mentioning 316L. The "L" stands for "low carbon." This version is often specified for food-grade equipment that requires a lot of welding. The lower carbon content minimizes harmful carbide precipitation during welding, which preserves corrosion resistance at the weld seams—a critical area for hygiene.

| Food/Process Type | Recommended Grade | Reason |

|---|---|---|

| Kitchen Countertops, Utensils | 304 | General use, low corrosivity |

| Dairy and Brewery Tanks | 304 | Neutral pH, standard application |

| Tomato Sauce Kettles | 316 / 316L | High acidity, prevents pitting |

| Meat Curing & Brining | 316 / 316L | High salt (chloride) content |

| Pharmaceutical Processing | 316 / 316L | High purity, resistance to cleaning agents |

What are the disadvantages of 316 stainless steel?

With its superior corrosion resistance, 316 stainless steel can seem like the ultimate material. But assuming it has no downsides can lead you to specify it for every project, which can needlessly inflate your budget. While it is an excellent material, 316 does have a few disadvantages you must consider.

The primary disadvantage of 316 stainless steel is its significantly higher cost compared to 304. It can also be slightly more difficult to machine due to its toughness. Furthermore, in specific high-temperature (above 60°C) and high-chloride environments, it can be susceptible to a failure mode called stress corrosion cracking.

No material is perfect for every situation. Understanding the limitations of 316 is just as important as understanding its strengths. It ensures you use this premium material only when its benefits truly outweigh its drawbacks.

The Trade-Offs of a Premium Material

Let’s look at the main disadvantages in more detail:

-

Cost: This is the most significant and practical disadvantage. As we’ve discussed, the molybdenum and higher nickel content make 316 more expensive. For many applications, this extra cost is simply unnecessary. If your part is going to be used in a dry, controlled indoor environment, paying a premium for marine-grade corrosion resistance is like buying snow tires for a car that will never leave the desert. It’s a waste of resources.

-

Machinability: While both 304 and 316 are readily machinable, 316 is generally considered slightly more difficult to work with. The same properties that make it tougher and more corrosion-resistant also mean it can cause more wear on cutting tools. As a machinist, I know that we sometimes have to adjust our cutting speeds and feeds for 316 to get the best results. This can translate to slightly longer cycle times, which can add a small amount to the final part cost, especially on high-volume production runs.

-

Susceptibility to Stress Corrosion Cracking (SCC): This is a more technical but critical disadvantage. In very specific conditions—when the part is under tensile stress and exposed to chlorides at elevated temperatures (typically above 140°F or 60°C)—316 can fail unexpectedly through SCC. Tiny cracks can form and spread through the material, leading to failure without any obvious signs of corrosion. This is a concern for equipment like heat exchangers or hot water tanks in chloride-rich environments.

Choosing 316 is about making a conscious decision to pay for performance. If you don’t need that specific performance, its biggest disadvantage is its impact on your budget.

Conclusion

The choice between 304 and 316 stainless steel is simple: 304 is the cost-effective workhorse for general use, while 316 is the premium option for harsh environments with salt or chemicals. Always match the material to the environment to balance performance and budget effectively.