Engineers often feel stuck between two choices: cheap, high-volume casting or precise, high-strength machining. This dilemma forces a compromise on either cost, quality, or speed. But what if you didn’t have to choose? What if you could combine them for a better result?

Yes, for many applications, a hybrid approach is the optimal solution. It involves using casting to create a "near-net shape" part and then using CNC machining to add high-precision features. This method leverages the low cost and material efficiency of casting with the tight tolerances and superior finish of machining, creating a better part at a balanced cost.

The idea of "one process fits all" is becoming outdated in modern manufacturing. I’ve seen countless projects where an engineer, like Alex, struggles with this exact problem. They have a part that’s too complex and costly to machine from a solid block, but casting alone can’t deliver the required precision for critical features. The solution isn’t to pick the lesser of two evils. The solution is to use both processes strategically. This hybrid method is a powerful tool that every product developer should understand.

What Exactly is a Hybrid Manufacturing Approach?

You hear the term "hybrid," and it might sound complicated or expensive. It feels like adding another step to the process, which could mean more things to go wrong. How does this combination of casting and machining actually work in practice?

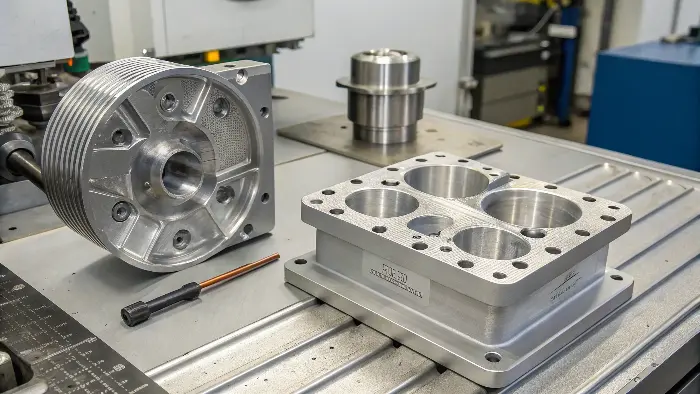

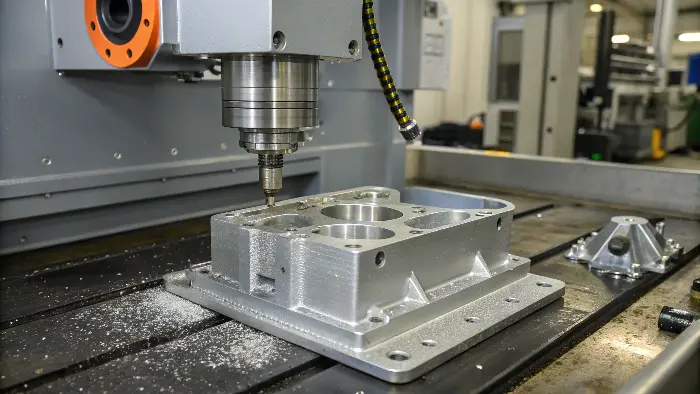

A hybrid approach is a two-step manufacturing process. First, a part is created using a casting method like die casting to get it close to its final shape (a near-net shape). Second, this cast part is put into a CNC machine for finishing operations. The CNC machine adds precise features like threaded holes, flat mating surfaces, or tight-tolerance bores.

Think of it like building a house. You don’t build the entire structure, including walls, plumbing, and electrical wiring, out of a single block of concrete. That would be incredibly wasteful and difficult. Instead, you pour the concrete foundation first (casting) to create the basic, strong shape. Then, carpenters, plumbers, and electricians come in to add the detailed, functional systems (machining). The process is the same for metal parts.

I remember working with a client on a complex housing for a medical device. The part had many cooling fins and a unique organic shape.

- Full CNC Machining: The quote was astronomical. Machining it from a solid block of aluminum would have taken over 10 hours per part, and about 80% of the expensive material would have ended up as chips on the floor.

- Full Casting: Casting could create the outer shape cheaply, but it couldn’t achieve the ±0.02mm tolerance required for the internal mounting points and the perfectly flat surface needed for an airtight seal.

The solution was a hybrid approach. We die-cast the near-net shape of the housing. This took care of the complex external fins and overall form. Then, we created a simple fixture to hold the cast part in a CNC mill. The machining cycle was less than 30 minutes, focused only on milling the sealing face, boring the mounting holes, and tapping the threads. The client got the best of both worlds: a complex shape at a low cost, with all the precision they needed.

The Two Core Stages of Hybrid Manufacturing

This process is all about efficiency. Each step does what it does best.

| Stage | Process Used | Purpose | Key Benefit |

|---|---|---|---|

| Stage 1: Forming | Die Casting, Investment Casting, etc. | Create the basic geometry of the part (near-net shape). | Saves massive amounts of raw material and reduces the need for lengthy rough machining. |

| Stage 2: Finishing | CNC Milling or Turning | Add high-precision features, improve surface finish, and meet tight tolerances. | Achieves a level of accuracy and surface quality that casting alone cannot provide. |

This method isn’t a compromise. It’s an optimization. It strategically uses the strengths of each process to overcome the weaknesses of the other, resulting in a superior and more cost-effective final product.

When Does It Make Sense to Combine Casting and Machining?

You understand the concept, but now you need to know when to apply it. Choosing this path for the wrong type of part could add unnecessary complexity and cost. So, what are the clear signals that a part is a perfect candidate for a hybrid approach?

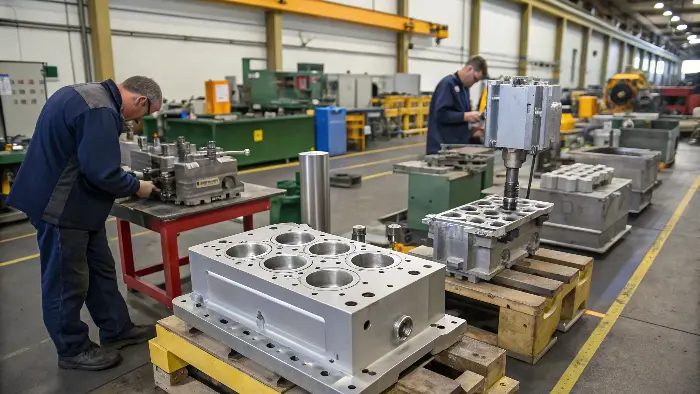

This method is ideal for parts with a mix of complex, non-critical geometry and specific, high-precision features. It’s the best choice for medium-to-high volume production of components like engine blocks, pump housings, or complex enclosures where the cost of full machining is prohibitive, but casting alone isn’t accurate enough.

The decision to use a hybrid process comes down to a simple analysis of your part’s features. If you look at your CAD model and see large, bulky sections combined with small areas that need to be perfect, you’re likely looking at a prime candidate. It’s about identifying where you can save money and where you must invest in precision.

Key Scenarios for a Hybrid Strategy

Let’s break down the most common situations where I recommend this approach to engineers like Alex.

1. Large Parts with High Material Waste

If you have to machine a large part from a solid billet, the cost of the raw material and the machine time for "roughing" (removing bulk material) can be enormous.

- Problem: A 10kg finished part might start as a 50kg block of aluminum. You pay for all 50kg, and you pay for the machine time to turn 40kg of it into low-value scrap chips.

- Hybrid Solution: Cast a 12kg near-net shape part. You save on 38kg of material and hours of rough machining time. The CNC machine then only needs to remove the final 2kg to hit the critical dimensions.

2. Parts Requiring High-Tolerance Features

Casting is not a high-precision process. Tolerances are often loose, and surfaces can be rough. If your part needs to interface perfectly with another component, casting alone won’t work.

- Problem: A cast gearbox housing needs to hold bearings. The bearing bores must be perfectly round and have a tolerance of ±0.015mm. Casting can’t achieve this.

- Hybrid Solution: Cast the entire housing to form the complex shape. Then, use a CNC machine to bore the bearing seats to the exact required diameter and tolerance.

3. Components Needing Superior Surface Finishes in Key Areas

Many parts require a very smooth surface for sealing, fluid flow, or aesthetics. The natural surface of a cast part is often textured or porous.

- Problem: A hydraulic manifold needs a perfectly flat surface for an O-ring seal to prevent leaks under high pressure. The slightly uneven surface of a raw casting would fail.

- Hybrid Solution: Cast the manifold block, then use a CNC mill to perform a "face mill" operation on the sealing surface, creating a perfectly flat, smooth finish (e.g., Ra 0.8μm) that ensures a reliable seal.

This table can help you decide:

| Ask Yourself This Question… | If You Answer "Yes," Consider… |

|---|---|

| Is my part larger than a shoebox? | Hybrid Approach |

| Does more than 50% of the material get removed during machining? | Hybrid Approach |

| Does my part have both complex curves and simple flat surfaces? | Hybrid Approach |

| Do I need tolerances tighter than ±0.2mm on only a few features? | Hybrid Approach |

| Does my part need a perfect seal or bearing fit? | Hybrid Approach |

How Does This Hybrid Approach Impact Cost and Lead Time?

You’re convinced of the technical benefits, but you still have to justify the project to your manager. The two biggest questions will always be: "How much will it cost?" and "When can we get it?" A hybrid process seems to have cost elements from both methods, which can be confusing.

The hybrid approach has a moderate upfront tooling cost from casting, but it dramatically lowers the per-part cost compared to full machining. This makes it cheaper than full machining for medium-to-high volumes. The initial lead time is longer due to mold creation, but the per-part production speed is much faster than full machining.

Let’s break down the financial and time-based trade-offs in a way that’s easy to understand. The key is that you are making a one-time investment in a casting mold to save a significant amount of money on every single part you produce thereafter.

A Clear Look at the Costs

The total cost is a blend of casting and machining costs, designed to minimize the most expensive parts of each.

- Tooling Cost: You still have to pay for a casting mold. This is a one-time investment, similar to pure casting. However, because you plan to machine the fine details later, the mold itself can sometimes be simpler and therefore slightly cheaper than a mold for a finished-quality cast part.

- Material Cost: This is where you see the biggest savings compared to full machining. Instead of buying a huge, expensive block of aluminum, you are using a near-net shape casting that has very little waste. The material savings alone can often justify the cost of the mold.

- Machining Cost: This cost is drastically reduced. Your CNC machine isn’t spending hours roughing out the basic shape. It’s performing quick, precise finishing operations that might only take a few minutes. You are paying for less machine time, less tool wear, and less labor per part.

Understanding the Lead Time

The timeline for a hybrid project has distinct phases.

| Phase | Pure CNC Machining | Hybrid Approach |

|---|---|---|

| Setup / Tooling | 1-3 Days (Programming) | 4-8 Weeks (Mold Design & Creation) |

| First Article | ~1 Week | ~9 Weeks |

| Production Speed (per 100 parts) | Slow (e.g., 200 hours) | Fast (e.g., 50 hours) |

As you can see, the initial lead time for the hybrid approach is much longer because you have to wait for the mold to be made. This makes it unsuitable for urgent prototypes. However, once the mold is ready, you can produce parts much faster and more cheaply than with full CNC machining. For any project with a stable design and a production volume of several hundred to many thousands of units, the initial time investment pays for itself very quickly. It’s a classic case of "go slow at the start to go fast later."

Conclusion

Hybrid manufacturing isn’t a compromise; it’s a powerful strategy. By combining the low-cost, material-efficient process of casting with the precision and quality of CNC machining, you can create optimized aluminum parts that are both high-performing and cost-effective, truly getting the best of both worlds.