Struggling to select the right aluminum and process for your aerospace parts? The wrong choice can lead to performance failures, safety risks, and budget overruns. You need a material and method that guarantees strength and precision without adding unnecessary weight or cost.

The best approach is to match the aluminum alloy and manufacturing process to the specific demands of the component. This involves evaluating properties like strength-to-weight ratio, fatigue resistance, and corrosion resistance. Then, select a process like forging, extrusion, or CNC machining that best achieves the desired geometry and material integrity for that part.

Choosing the right materials and methods is one of the most critical decisions in aerospace engineering. I’ve spent over a decade in manufacturing, helping engineers like you navigate these choices. It’s not just about picking the strongest metal. It’s about finding the perfect balance of performance, weight, and cost. A decision made on the drawing board has huge impacts on the production floor and, ultimately, in the air. Let’s walk through the key considerations together, so you can make these critical decisions with confidence.

What property of aluminium makes it most suited for aircraft manufacture?

You’re designing a new component and weight is a major concern. Every gram adds up, affecting fuel efficiency and payload capacity. But you can’t sacrifice strength, or you risk catastrophic failure. How do you find a material that is both incredibly strong and remarkably light?

The single most important property of aluminum for aircraft manufacturing is its high strength-to-weight ratio. It provides the necessary structural integrity to withstand flight stresses while being significantly lighter than steel. This allows for greater fuel efficiency, increased payload capacity, and better overall performance, making it the backbone of modern aviation.

When I first started in a CNC shop, I was amazed at how easily we could machine aluminum compared to steel. But its value in aerospace goes far beyond that. The real magic is in its density. Aluminum is about one-third the weight of steel. This isn’t just a small detail; it’s the foundation of modern aircraft design. Think about it this way: if a plane were made of steel, it might be too heavy to even get off the ground efficiently.

Let’s break down the key properties that make aluminum the star of the show.

The Unbeatable Strength-to-Weight Ratio

This is the main reason we use aluminum. Aerospace engineers are always fighting against gravity. A lighter aircraft needs less thrust to take off and fly, which means it burns less fuel. It can also carry more passengers or cargo. Certain aluminum alloys, when properly heat-treated, can achieve strengths comparable to mild steel but at a fraction of the weight. I remember working on a project for a drone manufacturer. They were trying to extend flight time, and we helped them switch a structural component from steel to a 7075 aluminum alloy. The weight savings directly translated into several extra minutes of flight, which was a huge win for their product.

Excellent Corrosion Resistance

Aircraft operate in harsh environments. They are exposed to moisture, salt spray, and extreme temperature changes. Aluminum naturally forms a thin, tough layer of aluminum oxide on its surface. This layer acts as a protective barrier, preventing the metal underneath from rusting or corroding. This is a huge advantage over many types of steel, which require heavy coatings or constant maintenance to prevent rust. This self-protecting feature means longer-lasting parts and lower maintenance costs over the aircraft’s lifespan.

Ease of Machinability and Formability

From a manufacturing perspective, aluminum is a dream to work with. It can be easily machined, bent, stretched, and formed into complex shapes like fuselage panels and wing skins. This is crucial because aircraft are not made of simple blocks. They are complex assemblies of precisely shaped parts. The ease with which we can shape aluminum helps keep manufacturing costs down and allows for more aerodynamic and efficient designs.

| Property | Aluminum | Steel | Titanium |

|---|---|---|---|

| Density (g/cm³) | ~2.7 | ~7.85 | ~4.5 |

| Strength | Good to High | High to Very High | Very High |

| Corrosion Resistance | Excellent | Poor to Good | Excellent |

| Cost | Low | Very Low | Very High |

As you can see, while titanium is stronger, its weight and cost are significantly higher. Steel is strong and cheap, but far too heavy. Aluminum hits that perfect sweet spot of being light, strong enough for most applications, corrosion-resistant, and cost-effective.

Which material property is most important when choosing materials for aerospace applications?

You’ve decided on aluminum, but now you face another challenge. One alloy offers superior strength, but another has better fatigue resistance. A third is easier to machine, saving costs. With so many competing factors, which property should you prioritize to ensure the safety and longevity of your component?

There is no single "most important" property; instead, it’s about achieving the right balance for the specific application. The most critical consideration is a combination of fatigue resistance, strength-to-weight ratio, and damage tolerance. The priority shifts depending on whether the part is a fuselage skin, a landing gear component, or an engine mount.

I often talk with engineers like Alex in Germany who are designing high-precision robotic parts. He understands that focusing on just one property, like ultimate tensile strength, can be a mistake. A part can be incredibly strong but fail prematurely if it can’t handle repeated stress cycles. In aerospace, we have to think about the entire life cycle of a part. It’s not a single event, but millions of them. The material must be robust enough to handle everything from ground operations to turbulence at 30,000 feet, day after day.

Let’s look at the key properties you must balance.

Fatigue Resistance

This is arguably the most critical safety consideration. Aircraft components are subjected to repeated cycles of stress during takeoff, flight, and landing. This is called cyclic loading. Fatigue is the weakening of a material caused by this repeated stress, which can lead to cracks and failure well below the material’s ultimate tensile strength. For parts like wings and the fuselage, which constantly flex and vibrate, high fatigue resistance is non-negotiable. We choose alloys and manufacturing processes specifically to maximize this property.

Damage Tolerance

This is the material’s ability to resist crack growth. It’s a fact of life that microscopic flaws can exist in materials or be introduced during manufacturing or service. Damage tolerance measures how well a material can contain these small cracks and prevent them from growing to a critical size between scheduled maintenance inspections. A material with good damage tolerance provides a safety buffer, ensuring that a small, undetected flaw doesn’t lead to a sudden, catastrophic failure. This is why aircraft undergo such rigorous inspection schedules.

Thermal Stability

Aircraft experience extreme temperature swings. A plane might sit on a hot runway in Dubai at 50°C (122°F) and then climb to an altitude where the outside temperature is -55°C (-67°F) in a matter of minutes. Materials expand and contract with these temperature changes. A material with good thermal stability maintains its strength and shape across this wide temperature range. This is especially important for parts near the engines or for supersonic aircraft where friction generates immense heat.

Choosing the right material is a balancing act. You are trading one benefit for another to find the optimal solution for a specific part’s job. This is where experience and collaboration between designers and manufacturing partners like us at QuickCNCs become so valuable.

What type of aluminum is used in the aerospace industry?

You know you need aluminum with a balance of properties, but the world of aluminum alloys is vast. Using a standard 6061 alloy might be great for a general-purpose bracket, but it won’t work for a high-stress fuselage frame. How do you navigate the different series to find the right one?

The aerospace industry primarily uses high-purity alloys from the 2xxx, 6xxx, and 7xxx series. Each series has unique properties based on its main alloying elements. 7xxx series (e.g., 7075) is used for high-stress parts like wing spars, 2xxx series (e.g., 2024) for fuselage skins due to its damage tolerance, and 6xxx series (e.g., 6061) for less critical structures.

When a client sends me a drawing, one of the first things I check is the material callout. The choice of alloy tells me a lot about the part’s function. An engineer specifying 7075-T6 is clearly concerned with maximum strength, while someone choosing 2024-T3 is likely focused on fatigue and fracture toughness. Understanding these differences is key to successful manufacturing. You can’t just substitute one for another. The heat treatment, machining parameters, and even the handling of the raw material change depending on the alloy.

Let’s dive into the main players and what makes them special.

The 7xxx Series: The Strength Champions

The 7xxx series alloys have zinc as their primary alloying element, with magnesium and copper also added. These are the strongest of all aluminum alloys.

- Key Alloy: 7075. Often called the workhorse of the aerospace industry.

- Properties: It has a strength-to-weight ratio comparable to many steels. After heat treatment (the -T6 temper is very common), it becomes incredibly strong and hard.

- Applications: Because of its high strength, it’s used for critical structural parts that carry a lot of stress. This includes wing spars (the main structural beams of the wing), fuselage frames, and other load-bearing components. The trade-off is that it can be less resistant to stress corrosion cracking, so proper design and surface treatments are essential.

The 2xxx Series: The Tough Guys

The 2xxx series alloys use copper as their main alloying element. While not as strong as the 7xxx series, they have a major advantage: superior damage tolerance and fatigue resistance.

- Key Alloy: 2024. Another classic aerospace alloy.

- Properties: It is known for its excellent fracture toughness. This means it’s very good at resisting the growth of cracks.

- Applications: This property makes it ideal for fuselage skins and wing skins. These parts need to be tough and resilient to handle the constant flexing and potential for small impacts (like from ground service vehicles or hail) without developing dangerous cracks.

The 6xxx Series: The All-Rounders

The 6xxx series alloys contain magnesium and silicon. They are not as strong as the 2xxx or 7xxx series, but they offer a great combination of good strength, excellent corrosion resistance, and superior formability and weldability.

- Key Alloy: 6061. This is one of the most versatile and widely used aluminum alloys in the world.

- Properties: It’s easy to machine, weld, and extrude into complex shapes.

- Applications: In aerospace, you’ll find it used for secondary structural components that don’t carry the primary flight loads. This includes things like floor panels, winglets, and fairings that cover gaps between different parts of the aircraft.

| Alloy Series | Primary Element | Key Characteristic | Common Aerospace Application |

|---|---|---|---|

| 7xxx (e.g., 7075) | Zinc | Highest Strength | Wing Spars, Fuselage Frames |

| 2xxx (e.g., 2024) | Copper | Damage Tolerance, Fatigue Resistance | Fuselage Skin, Wing Skin |

| 6xxx (e.g., 6061) | Magnesium & Silicon | Corrosion Resistance, Formability | Secondary Structures, Fairings |

How do you make aerospace grade aluminum parts?

You’ve selected the perfect alloy. Now, how do you turn that raw material into a finished, flight-ready component? A simple block of 7075 aluminum is useless until it’s shaped. The manufacturing process you choose is just as critical as the alloy itself, as it directly influences the final strength and reliability of the part.

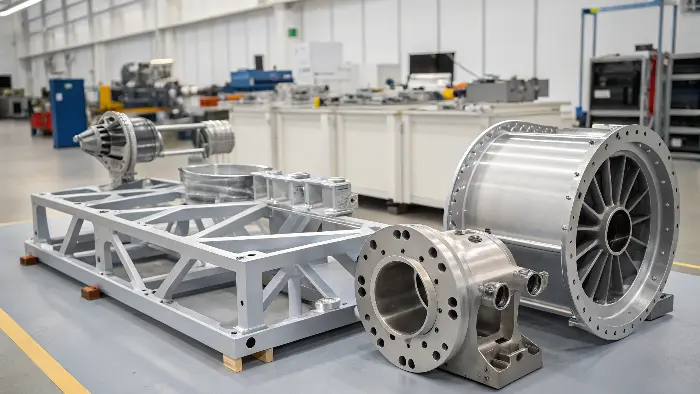

Aerospace-grade aluminum parts are made using processes that control the material’s internal grain structure to maximize strength and integrity. Key methods include forging for high-stress parts like landing gear, extrusion for long, uniform parts like stringers, and precision CNC machining to create complex final geometries from billets or forgings while holding tight tolerances.

The manufacturing process does more than just create a shape. It fundamentally changes the properties of the metal. I’ve seen this firsthand many times. A part forged into its near-final shape will have a grain flow that follows the contours of the part, making it much stronger than the same part machined from a solid block of rolled plate. Understanding these differences is crucial for any engineer sourcing critical components. It’s the difference between a part that simply meets the drawing and a part that is truly optimized for its purpose.

Let’s explore the primary manufacturing methods.

Forging

Forging is the process of shaping metal using localized compressive forces. The aluminum billet is heated and then pressed or hammered into a die.

- Why it’s used: This process refines the grain structure of the aluminum, aligning it with the shape of the part. This continuous grain flow eliminates internal voids and creates components with exceptional strength, fatigue resistance, and impact toughness.

- Common Applications: Forging is the go-to method for the most critical, high-stress components on an aircraft. This includes landing gear, bulkheads, and engine mounts. These are parts where failure is not an option.

Extrusion

Extrusion involves pushing a heated aluminum billet through a die to create a long, continuous profile with a fixed cross-sectional shape.

- Why it’s used: It’s an efficient way to produce long parts with complex cross-sections that are consistent along their entire length.

- Common Applications: Think of the long structural pieces that run the length of the fuselage and wings, called stringers and stiffeners. These are almost always extruded. Window and door frames are also common applications.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive process where a computer-controlled cutting tool removes material from a solid block (a billet) or a near-net shape part (like a forging) to create the final geometry.

- Why it’s used: It offers incredible precision and the ability to create highly complex shapes that would be impossible with other methods. It’s essential for achieving the tight tolerances (often down to ±0.01mm) required for aerospace components to fit together perfectly.

- Common Applications: CNC machining is used everywhere. It can be the primary method for creating complex parts like hydraulic manifolds or brackets from a solid billet. It’s also a critical secondary step for finishing forged or extruded parts, adding holes, pockets, and other precise features. At QuickCNCs, this is our specialty—turning raw material or a rough forging into a finished, flight-ready part.

Conclusion

In aerospace, selecting the right aluminum alloy and manufacturing process is a critical balancing act. Success depends on matching the material’s properties—like strength-to-weight ratio and fatigue resistance—with the specific demands of the component. Processes like forging, extrusion, and CNC machining are chosen to optimize both geometry and performance.