Are you struggling to connect your design concepts to flawless final products? A small oversight in design can cause big headaches in production, leading to delays and budget overruns. Understanding the link between design, manufacturing, and automation is the key to turning your ideas into reality efficiently.

Machine design, manufacturing, and automation are three parts of a single, powerful system. Design creates the blueprint for a part. Manufacturing uses processes like CNC machining to physically create it. Automation applies technology to make that process faster, more accurate, and repeatable. Together, they transform a digital file into a high-quality physical component with minimal error.

This synergy is something I’ve seen transform projects for over a decade. As an engineer, mastering how these three pillars support each other is no longer optional; it’s essential for staying competitive. It’s the difference between a project that struggles and one that succeeds smoothly. Let’s break down each element to see how you can leverage them for your own work.

What is the role of machine design in manufacturing?

Ever had a brilliant design on your screen that turned into a manufacturing nightmare? This disconnect leads to wasted materials, blown deadlines, and frustrating redesigns. The solution is to treat machine design as the critical first step that ensures a part can actually be made well.

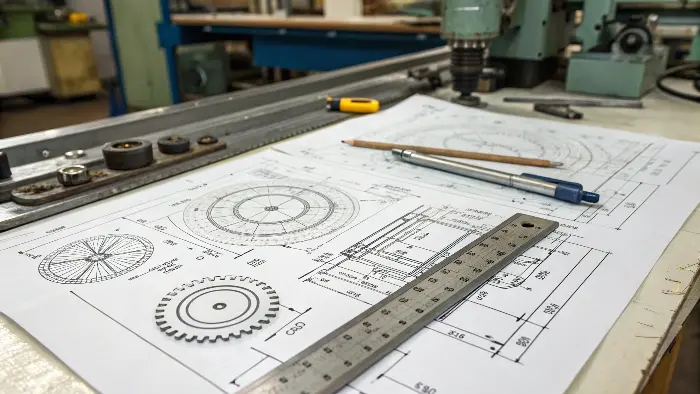

The main role of machine design in manufacturing is to create a detailed, functional, and manufacturable blueprint. It goes beyond just shape and size. It defines materials, tolerances, and features in a way that is efficient and cost-effective for production methods like CNC machining. Good design is the foundation of good manufacturing.

I’ve seen countless projects come through my shop, and the best ones always start with a solid design. It’s not just about creating something that works in theory. It’s about creating something that can be built in the real world, on time and on budget. This is where the concept of Design for Manufacturability (DFM) becomes so important. It’s a way of thinking that I encourage all my clients, especially engineers like Alex in Germany who demand high precision, to adopt from day one.

Designing for the Real World

A design is more than just a pretty picture in a CAD program. It’s a set of instructions for a machine. If those instructions are unclear or impossible to follow, the machine can’t do its job. The design phase must consider the physical limitations and capabilities of the manufacturing process. For CNC machining, this means thinking about tool access, material properties, and how the part will be held in place. A simple change, like increasing an internal corner radius, can be the difference between using a standard tool and needing a costly custom one.

Key Principles of Design for Manufacturability (DFM)

DFM is a proactive approach. It involves designing parts in a way that makes them easy and economical to manufacture. This doesn’t mean compromising your design’s function. It means achieving that function in the smartest way possible. I remember a client who sent us a design for an aluminum housing. It was a great design, but it had very deep pockets with sharp internal corners. Machining this as-is would have been slow and expensive. I gave him a call and we discussed adding a small radius to the corners and slightly reducing the pocket depth. These minor tweaks didn’t affect the part’s performance but cut the machining time by nearly 40%. That’s the power of DFM.

Here’s a simple table showing how small design choices have a big impact:

| Design Feature | Poor DFM Practice | Good DFM Practice | Manufacturing Impact |

|---|---|---|---|

| Internal Corners | Sharp, 0mm radius | Radius > 1mm | Allows use of standard end mills, faster machining. |

| Wall Thickness | Very thin walls (<0.8mm) | Uniform, thicker walls | Reduces vibration, prevents warping, improves stability. |

| Hole Depth | Very deep holes (>10x diameter) | Shallower holes | Prevents tool breakage, improves accuracy. |

| Tolerances | Unnecessarily tight everywhere | Tight only where critical | Lowers machining cost and time, reduces scrap rate. |

Thinking about these factors from the start saves everyone time and money. It makes the entire process, from quoting to final delivery, much smoother.

What is mechanical manufacturing and automation?

Relying on purely manual manufacturing is slow and introduces human error. This inconsistency can compromise an entire batch of high-tolerance parts, which is a risk no engineer wants to take. Combining mechanical manufacturing with automation creates a system that is reliable, repeatable, and highly efficient.

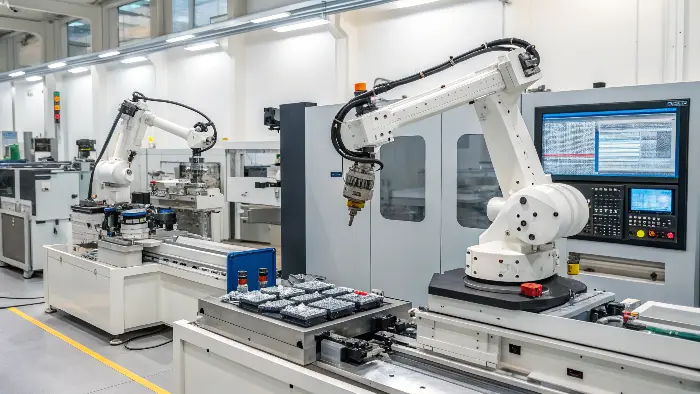

Mechanical manufacturing is the physical process of shaping materials into parts, often using machines like mills and lathes. Automation is the use of technology—like computer controls (CNC), robotics, and software—to perform these manufacturing tasks with little human help. Together, they create a system that produces parts with incredible precision and consistency at scale.

In my early days, I spent a lot of time manually operating machines. I learned the feel of the metal and the sound of a good cut. But I also learned how easy it is to make a small mistake that ruins a part. Today, at QuickCNCs, automation is our partner. It doesn’t replace the skill of the machinist; it enhances it. It allows us to deliver the tight tolerances and consistent quality that engineers like Alex depend on, whether they order 10 parts or 10,000.

The Core of Modern Manufacturing

At its heart, manufacturing is about shaping material. The two main approaches today are subtractive and additive.

- Subtractive Manufacturing: This is the classic method. You start with a solid block of material (like aluminum or steel) and remove material to reveal the final shape. CNC machining is the perfect example. It’s known for its high precision, excellent surface finish, and strength.

- Additive Manufacturing: This is a newer approach, commonly known as 3D printing. It builds a part layer by layer from a digital file. It’s great for complex geometries and rapid prototyping, but often can’t match the strength or tolerances of CNC machining for production parts.

How Automation Transforms Manufacturing

Automation takes the core manufacturing process and puts it on steroids. It’s not just one thing; it’s a system of technologies working together.

- Computer Numerical Control (CNC): This is the brain of the machine. Instead of a human turning dials, a computer reads a G-code file (exported from your CAD model) and executes the machining operations with flawless precision.

- Robotic Automation: We use robotic arms for tasks like loading raw material into a CNC machine and unloading the finished parts. This allows the machines to run 24/7 without breaks, dramatically increasing output.

- Automated Quality Control: After a part is made, it needs to be inspected. We use automated Coordinate Measuring Machines (CMMs). A CMM uses a probe to automatically measure hundreds of points on the part and compares them to the original CAD data, ensuring every dimension is within tolerance.

Here’s how an automated workflow compares to a manual one:

| Process Step | Manual Workflow | Automated Workflow | Benefit of Automation |

|---|---|---|---|

| Loading Material | Operator manually clamps block. | Robotic arm places and clamps block. | Faster, runs continuously. |

| Machining | Operator manually controls machine. | CNC program runs automatically. | Perfect repeatability, higher precision. |

| Part Unloading | Operator removes finished part. | Robotic arm unloads part. | Reduces cycle time, increases safety. |

| Inspection | Operator uses calipers/micrometers. | CMM automatically inspects part. | More accurate, faster, full report generated. |

This level of automation is how we guarantee that the 100th part is identical to the first one.

What is automation machinery manufacturing?

You need to automate your factory, but where do the robots and machines come from? These systems must be incredibly reliable, because if one machine goes down, your entire production line can grind to a halt. This is where the specialized field of automation machinery manufacturing comes in.

Automation machinery manufacturing is the specific industry that designs, builds, and integrates the machines used for automation. This includes creating everything from robotic arms and conveyor belts to custom assembly stations and automated inspection systems. It’s about building the physical hardware that makes industrial automation a reality.

While QuickCNCs focuses on making the custom parts for these machines, I work closely with companies that build them. They are our customers. They come to us for the high-precision machined components that are the skeleton and heart of their automation systems. The quality of our parts directly impacts the reliability and performance of their final machine. It’s a huge responsibility, and it gives us a unique view into what it takes to build the machines that build other products.

The Building Blocks of an Automation Machine

An automation machine, like a robot, is a complex assembly of many specialized components. Each one has a critical job to do.

- Controllers (PLCs): This is the brain. A Programmable Logic Controller (PLC) is a ruggedized industrial computer that runs the program and tells all the other parts what to do and when.

- Actuators: These are the muscles. They convert energy (electrical, pneumatic, or hydraulic) into motion. Examples include motors, cylinders, and servos that move the machine’s arms and tools.

- Sensors: These are the eyes and ears. Sensors detect things like position, pressure, temperature, and the presence of a part. They provide feedback to the controller so it can make smart decisions.

- End-Effectors: This is the "hand" of the robot or machine. It’s the tool that directly interacts with the product, such as a gripper, a welding torch, or a screwdriver.

The Process of Building Automation Machinery

Creating a custom automation machine is a major engineering project. We are often involved in the most critical step: machining the custom components.

- Design & Simulation: Engineers design the entire machine in CAD, simulating its movements to ensure it will work correctly before any metal is cut.

- Frame Fabrication: A strong, stable frame is welded and assembled to serve as the machine’s foundation.

- Component Machining: This is where we come in. The builders send us drawings for custom parts like mounting brackets, actuator housings, and precision shafts. These parts must be machined to extremely tight tolerances because they hold all the other components in perfect alignment.

- Assembly & Wiring: All the commercial and custom components are assembled onto the frame, and the complex wiring for power and data is installed.

- Programming & Testing: Finally, software engineers write the code for the PLC. The machine is then rigorously tested and fine-tuned to ensure it operates safely, reliably, and efficiently.

We recently machined a set of complex aluminum mounting plates for a robotics company in Europe. These plates held the main servo motors for a new robotic arm. The hole positions had to be accurate to within ±0.01mm. Any error would cause misalignment in the robot’s joints, leading to inaccurate movements. It’s this level of precision in the components that makes the final automation machinery successful.

What is mechanical design automation?

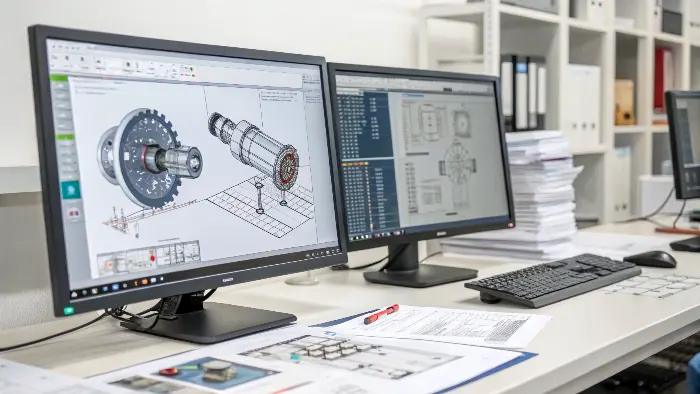

As an engineer, you know that designing complex systems manually is incredibly time-consuming. All the repetitive tasks, calculations, and checks slow down innovation and can even lead to mistakes. Mechanical design automation uses software to streamline and accelerate the design process itself.

Mechanical design automation is the use of software and algorithms to automate tasks within the engineering design process. This isn’t about replacing the engineer. It’s about giving them powerful tools like parametric modeling, generative design, and automated simulation to create better designs faster and explore more possibilities than would be possible manually.

This is the cutting edge, and it’s changing how we think about design. Instead of just being a tool for drawing, CAD software is becoming an active partner in the design process. It helps engineers optimize their work before it ever gets to a machine shop like mine. When an engineer uses these tools effectively, the designs they send us are already optimized for performance and manufacturability. This makes my job easier and gets them a better part, faster.

From Parametric to Generative Design

The automation of design exists on a spectrum.

- Parametric Modeling: This is a feature most modern CAD software has. You design a part using parameters and constraints. If you need to change the length of the part, you just change one number, and the entire model updates automatically. This is a huge time-saver for making design revisions.

- Generative Design: This is a more advanced, AI-driven approach. Instead of drawing the part yourself, you tell the software the requirements: where it needs to mount, what loads it must withstand, what material to use, and any constraints. The AI then generates hundreds or even thousands of optimized design options that meet those criteria. The engineer then chooses the best option. This can create incredibly lightweight and strong parts that a human might never have thought of.

How Automated Design Improves Manufacturing

The benefits of design automation extend directly to the factory floor. When engineers use these tools, they solve problems before they happen.

- Automated Tolerance Analysis: Software can automatically analyze the "stack-up" of tolerances in an assembly. This predicts whether the parts will fit together correctly, preventing costly rework after manufacturing.

- Integrated Simulation (FEA): Finite Element Analysis (FEA) tools are now built right into CAD software. An engineer can apply virtual forces to their design to see how it will bend or break. This reduces the need for multiple expensive physical prototypes. I’ve seen clients use simulation to reduce the weight of a part by 30% while maintaining its strength, saving them significant material costs on a large production run.

Here’s a look at how an automated design workflow changes the game:

| Design Task | Traditional Workflow | Automated Workflow | Outcome |

|---|---|---|---|

| Creating a Part | Manually draw every line and feature. | Define parameters; let software build geometry. | Much faster design creation. |

| Design Iteration | Manually redraw for each change. | Change a parameter; model updates instantly. | Revisions take minutes, not hours. |

| Optimization | Engineer’s intuition, trial-and-error. | Generative design AI suggests optimal forms. | Lighter, stronger, more efficient parts. |

| Validation | Build and break physical prototypes. | Run digital simulations (FEA) in minutes. | Fewer prototypes, faster development cycle. |

By embracing these tools, engineers can focus on innovation, not on repetitive drafting tasks.

Conclusion

Machine design, manufacturing, and automation are not separate disciplines. They are a connected, repeating cycle. Great design enables efficient manufacturing. Automation makes both design and manufacturing faster and more precise. Understanding this powerful synergy is the key to success in modern engineering and product development.