Are you trying to break into the manufacturing industry but feel stuck choosing between a CNC or a CAD/CAM course? Picking the wrong one can slow down your career start. Let’s look at which path gives you the most valuable, job-ready skills in the shortest amount of time.

For a short-term course aimed at quick employment, a CNC programming and operation course is often the better choice. It provides direct, hands-on skills that are immediately in demand on the factory floor. While CAD/CAM is crucial, mastering it often benefits from a foundational understanding of the CNC machining process itself, making CNC a more practical first step for many.

So, we’ve established that a CNC course might be your quickest path to a job. But that’s just the surface. To really make an informed decision, you need to understand what each path entails, its long-term value, and how they fit together. Let’s dig deeper into the specifics of each type of training and what you can expect from them.

How long does it take to learn CNC?

Thinking about a CNC career but worried about a long, drawn-out training period? You don’t want to spend years in a classroom when you could be earning and gaining real-world experience. The good news is, you can become proficient in CNC basics surprisingly quickly.

You can learn the fundamentals of CNC operation and basic G-code programming in a short-term course lasting anywhere from 3 to 6 months. This is usually enough to qualify for an entry-level position as a CNC operator. Gaining true mastery and becoming a skilled machinist, however, is a continuous process that takes years of hands-on experience on the shop floor.

Learning CNC machining is a journey, not a destination. It happens in stages, and the timeline can vary for everyone. From my years in the industry, I’ve seen people progress through a few common phases. It starts with formal training but truly develops on the shop floor, where theory meets reality. Understanding these stages can help you set realistic expectations for your career path. Let’s break down what that journey looks like, from your first day in a course to becoming a master of the craft.

The Initial Training Phase (3-6 Months)

This is where everyone starts. A good short-term course is designed to get you job-ready for an entry-level role. In these first few months, you’ll cover the absolute essentials. You’ll learn about workshop safety, which is the most important lesson of all. You’ll be taught how to read and interpret blueprints and technical drawings. You’ll also brush up on the shop math needed for calculations. The core of the training will be an introduction to G-code and M-code, the languages that control the machines. You’ll learn how to set up a CNC machine, which includes clamping the workpiece (workholding) and setting tool offsets. The goal of this phase is to get you comfortable enough to run your first simple parts safely and correctly. I still remember the feeling of running my first program and holding a finished part that matched the blueprint. That initial training is all about building that foundational confidence.

Becoming a Proficient Machinist (1-3 Years)

Once you have your certificate and land your first job as a CNC operator, the real learning begins. The first one to three years are about moving beyond just pushing buttons. This is where you become a true machinist. You’ll learn how to troubleshoot problems when a machine alarms out or a part isn’t meeting spec. You’ll start to understand how to optimize toolpaths to make parts faster and with a better surface finish. You will work with a variety of materials, from aluminum and steel to plastics, and learn their unique behaviors. This is also when you might get exposure to more complex machine setups, like 4-axis or even 5-axis machining. An operator runs the program; a machinist understands it and can improve it. This is the stage where your value to the company, and your paycheck, really starts to grow.

The Path to Mastery (3+ Years)

After a few years of solid experience, you are on the path to becoming a master. This is where you transform from a skilled machinist into a manufacturing expert. You’ll be trusted with the most complex and expensive jobs. You might be programming parts from scratch, designing custom fixtures, and developing entire manufacturing processes for new products. At this level, you’re not just solving problems; you’re preventing them. Many masters become mentors to the newer machinists, a shop foreman, or move into roles like manufacturing engineering or production management. Technology is always changing, so even at this stage, the learning never stops.

How long is the CAD CAM course?

Are you interested in the design and programming side of manufacturing with CAD/CAM? But you’re concerned about how long it will take to learn the complex software and start creating toolpaths. The good news is that learning the basics of CAD/CAM software can be achieved in a focused, short-term program.

A typical CAD/CAM certificate course can range from 6 to 12 months. This will cover software proficiency (like Fusion 360, Mastercam, or SolidWorks), design principles, and generating toolpaths for CNC machines. Similar to CNC, becoming an expert who can optimize complex parts for manufacturing requires ongoing practice and deeper knowledge of machining principles.

A CAD/CAM course combines two powerful skill sets: design and manufacturing. The curriculum is usually split to cover both aspects, as one builds upon the other. It’s not just about learning to use a piece of software; it’s about learning a workflow that turns an idea into a physical object. The best programs teach you how to think like both a designer and a machinist. Let’s explore what you’ll learn in each part of the course and why practical experience is so important to tie it all together.

Foundational CAD Skills (First Half)

The first part of any CAD/CAM program focuses on the "CAD" – Computer-Aided Design. This is where you learn to create the digital blueprint. You’ll start with the basics of the software interface, then move into 2D sketching and creating 3D solid models. You’ll also learn how to create assemblies, which is how multiple parts fit together, and how to generate the formal 2D technical drawings that are used on the shop floor. This skill set is incredibly valuable on its own. At QuickCNCs, we work with engineers like Alex from Germany who provide us with detailed models. An accurate, well-designed model is the foundation for everything that follows. A bad model can cause huge delays and costly mistakes, so getting this part right is critical.

The CAM Integration (Second Half)

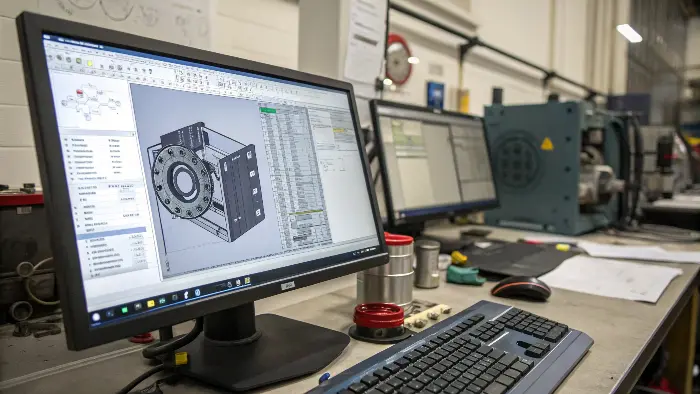

Once you can create a model, the next step is to learn the "CAM" – Computer-Aided Manufacturing. This is the bridge between the digital design and the physical machine. In this phase, you’ll import a 3D model into the CAM software and learn to generate the toolpaths that tell the CNC machine how to move. This involves a lot more than just clicking a button. You have to choose the right cutting tools, set the correct speeds and feeds for the material, and define the cutting strategies. For example, you’ll use a "roughing" strategy to remove material quickly and a "finishing" strategy to create a smooth, accurate final surface. You’ll also learn to run simulations to check for any crashes or errors before sending the program to the machine.

Why Practical Experience Matters

A certificate shows you know the software, but true skill comes from experience. The real art of CAM programming is creating toolpaths that are not just correct, but also efficient and safe. An efficient program saves time and money. A safe program protects the operator, the machine, and the part. This requires a deep understanding of how different materials cut, how long tools will last, and the specific capabilities and limits of the CNC machine. This is precisely why many of the best CAM programmers I know started their careers as CNC machinists. They have a practical feel for the process that you just can’t get from a classroom alone.

Which is better, CAD or CAM?

You hear the term "CAD/CAM" used together all the time, but are they the same thing? Focusing on the wrong one could lead you down a career path that doesn’t match your interests, whether that’s creative design or hands-on production. Let’s clarify the distinct roles of CAD and CAM to help you choose.

Neither is "better"; they are two different stages of the same process. CAD (Computer-Aided Design) is for creating the digital model of a part. CAM (Computer-Aided Manufacturing) is for using that model to generate instructions (toolpaths) for the CNC machine. Your choice depends on whether you prefer design and engineering (CAD) or manufacturing and production (CAM).

Choosing between a focus on CAD or CAM is really about choosing what part of the product development process excites you most. Do you enjoy imagining new things and bringing them to life on a screen? Or do you get satisfaction from figuring out the best way to physically create something? Both are essential roles in modern manufacturing, and they work very closely together. Let’s look at the specific roles and skills for each to see which one is a better fit for you.

The Role of a CAD Specialist

A CAD specialist is a designer at heart. Their main focus is on the conceptual and engineering phases. They take an idea or a set of requirements and turn it into a detailed digital model. Their work is the very first step in making a physical product. Typical job titles include Mechanical Designer, Drafter, or Design Engineer. To succeed in CAD, you need creativity, a strong sense of spatial awareness, and extreme attention to detail. You also need a solid understanding of engineering principles like GD&T (Geometric Dimensioning and Tolerancing) to ensure your designs can actually be made. In short, a CAD specialist answers the question, "What should we make and what does it look like?"

The Role of a CAM Specialist

A CAM specialist is a manufacturing strategist. They take the finished design from the CAD specialist and figure out the best way to produce it. Their world is one of production, process planning, and optimization. Job titles for this role include CAM Programmer, CNC Programmer, or Manufacturing Engineer. A great CAM programmer is an expert problem-solver. They need a deep knowledge of machining processes, material properties, cutting tools, and workholding techniques. Their job is to create the G-code that will produce the part accurately, efficiently, and safely. A CAM specialist answers the question, "How do we make this?"

To make it clearer, here is a simple table comparing the two:

| Feature | CAD (Computer-Aided Design) | CAM (Computer-Aided Manufacturing) |

|---|---|---|

| Primary Goal | Create a digital 2D/3D model | Create machine instructions (toolpaths) |

| Key Question | "What does the part look like?" | "How do we cut this part?" |

| Core Skills | Design, drafting, 3D modeling | Machining strategy, tool selection, G-code |

| Typical Software | SolidWorks, AutoCAD, Inventor | Mastercam, Fusion 360, GibbsCAM |

| Job Roles | Design Engineer, Drafter | CNC Programmer, Manufacturing Engineer |

Is a CNC certificate worth it?

Are you considering investing your time and money into a CNC certificate program? You might be wondering if it will actually lead to a good job, or if you’ll just end up with a piece of paper and no real prospects. Let me assure you, a CNC certificate is a powerful tool that proves your foundational knowledge to employers.

Yes, a CNC certificate is absolutely worth it, especially for someone starting their career. It demonstrates to employers that you have a formal understanding of safety, machine operation, and basic programming. It significantly lowers the barrier to entry for your first job as a CNC operator and provides a structured foundation upon which you can build years of valuable, hands-on experience.

In my role at QuickCNCs, I’ve been involved in hiring and managing production teams for years. I can tell you firsthand that when we look at candidates for entry-level positions, a certificate makes a huge difference. It’s more than just a piece of paper; it’s a signal to us about your commitment, your knowledge, and your potential. Let’s break down exactly why that certificate is so valuable.

What a Certificate Tells an Employer

When I see a CNC certificate on a resume, it tells me several important things. First, it shows initiative. This person invested their own time and money to learn a skill, which shows they are serious about this career. Second, it confirms they have been formally trained in safety procedures. In a machine shop, safety is our number one priority, and knowing a new hire already has this foundation is a huge relief. Third, it means they speak the language of the shop. They understand blueprints, G-code, and concepts like tool offsets. This drastically reduces the amount of time we need to spend on basic training. I once hired two junior operators around the same time. One had a certificate, the other just claimed some experience. The certified operator was safely setting up and running jobs within a week. The other person needed constant supervision for basic tasks, and we ultimately had to let them go. The certificate made all the difference in their readiness for the job.

The Return on Investment (ROI)

Let’s talk about the money. A short-term CNC course might cost a few thousand dollars. But the starting salary for a CNC operator is quite competitive, and you can earn that investment back very quickly, often within the first few months of working. More importantly, that certificate is the first step on a clear career ladder. You start as an operator, but with experience, you can become a higher-paid CNC machinist, a CNC programmer, a quality control inspector, or even a shop foreman. The initial investment in your education unlocks years of earning potential. It’s one of the best financial returns you can get in a skilled trade.

Certificate vs. Experience

Now, it’s true that in the long run, experience is king. A machinist with 10 years of experience is more valuable than a new graduate with a certificate. However, the certificate is the key that unlocks the door to getting that first year of experience. It solves the classic "chicken-and-egg" problem: you can’t get a job without experience, but you can’t get experience without a job. The certificate breaks that cycle. It validates your skills to an employer and convinces them to give you a chance. It is your proven, validated starting point in a rewarding career.

Conclusion

For a quick and direct entry into a manufacturing career, a CNC course is your best bet. It provides the foundational, hands-on skills that employers are looking for right now. CAD/CAM is a vital and lucrative field, but it often builds upon that practical machining knowledge. Choose your path, get certified, and start building your career.