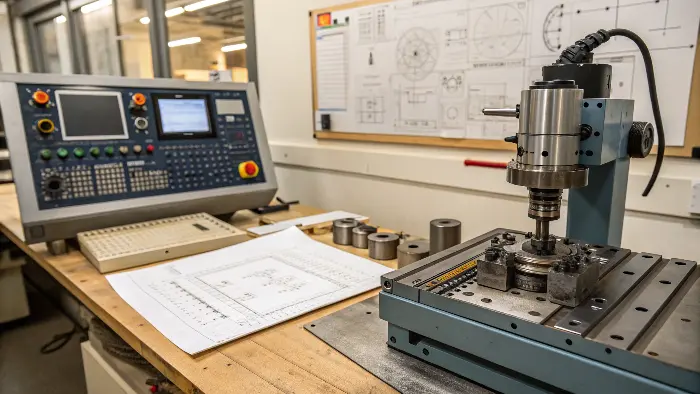

As an engineer, your designs look perfect on screen, but you face constant back-and-forth with the machine shop. This communication gap can kill your project’s momentum and budget. Understanding CNC machining gives you the power to design for manufacturability from day one.

CNC training is extremely valuable for an engineer. It provides a deep understanding of manufacturing constraints, capabilities, and costs. This knowledge allows you to create more efficient, cost-effective, and practical designs. You’ll communicate better with machinists, reduce revisions, and get your parts made faster and more accurately. It’s a direct investment in your effectiveness as a designer.

I’ve seen this firsthand many times. Brilliant engineers design incredible parts, but a small oversight in how that part will be machined can cause major headaches. It’s not about becoming a machinist yourself. It’s about speaking the same language as the people who bring your designs to life. So, let’s break down what this training really means for your career and your projects.

Is CNC considered engineering?

You see CNC machining as a separate, hands-on trade, while engineering is about theory and design. This separation can create a blind spot in your work. This disconnect leads to designs that are difficult to machine, causing friction with your manufacturing partners and delaying your projects.

CNC machining is not engineering in the traditional academic sense, but it is a highly technical field that applies engineering principles. It’s the practical execution of mechanical engineering concepts. A CNC machinist uses knowledge of materials, physics, and geometry—all core engineering subjects—to turn a digital design into a physical part. The two fields are deeply interconnected.

I’ll start by saying that a CNC machinist and a mechanical engineer have different job titles for a reason. But the line between them is blurrier than most people think. In my years of working with both, I see them as two sides of the same coin. The engineer creates the "what," and the CNC professional figures out the "how."

The Engineering in CNC Machining

Think about what a skilled machinist does. They don’t just press a button. They interpret engineering drawings, select the right materials, and choose the best cutting tools. They calculate speeds and feeds based on material hardness and tool geometry. This involves a deep understanding of material science, kinematics, and thermodynamics—all subjects an engineer studies. They are problem-solving in a real-world, physical environment. When I started my career on the shop floor, I quickly realized that every successful part was a small engineering victory.

Where the Roles Overlap and Diverge

Let’s look at a simple table to see the connection.

| Aspect | Mechanical Engineer’s Focus | CNC Machinist’s Focus | Shared Ground |

|---|---|---|---|

| Goal | Design a functional, reliable part or system. | Produce the part accurately and efficiently. | Creating a successful final product. |

| Tools | CAD software, simulation tools, calculations. | CAM software, CNC machines, cutting tools, gauges. | Technical drawings, GD&T. |

| Knowledge | Theory, material properties, stress analysis. | Practical application, tool paths, machine limits. | Material science, geometry. |

When an engineer like Alex designs a part with a tight tolerance, he’s using his engineering knowledge. When the machinist achieves that tolerance, they are applying their own deep technical expertise. The best projects happen when both sides understand and respect each other’s domain. That’s why I always say CNC isn’t just a trade; it’s an engineering discipline in practice.

Is learning CNC programming worth it?

You rely on CAM software to generate G-code and let the machinists handle the rest. Why bother learning the code yourself? But when a part fails or a quote comes back surprisingly high, you’re left guessing why. You can’t troubleshoot a process you don’t understand.

Yes, learning the fundamentals of CNC programming is absolutely worth it for an engineer. You don’t need to become an expert G-code writer. However, understanding how toolpaths are created, how machines interpret commands, and what makes a program efficient will make you a much better designer. It allows you to spot potential manufacturing issues directly in your design phase, long before any metal is cut.

I remember a project with a client from Germany, an engineer much like Alex. He designed a complex aluminum housing with many deep pockets. The quote he received from a supplier was higher than expected. He asked me to review it. I showed him the G-code simulation. The machine needed to use a long, thin end mill to reach the bottom of the pockets. This required slow speeds and multiple shallow passes to avoid tool breakage and chatter. This dramatically increased the machine time.

From Design Flaw to Design for Manufacturability (DFM)

Once he understood the "why" behind the cost, he saw the solution. He slightly modified the design, making the pockets wider and adding a generous radius to the internal corners. This simple change allowed us to use a shorter, more rigid cutting tool. The new program was much more efficient. The machine time was cut by nearly 40%. He didn’t write a single line of G-code, but his understanding of it saved the project’s budget. This is the power of DFM in action.

Key CNC Programming Concepts for Engineers

You don’t need to memorize every G-code and M-code. Focus on the concepts:

| Concept | Why It Matters for an Engineer | Design Impact |

|---|---|---|

| G00 (Rapid Move) | This is non-cutting movement. Minimizing it saves time. | Group features together to reduce travel distance between cuts. |

| G01 (Linear Move) | This is straight-line cutting. The core of most programs. | Design with straight lines and simple profiles where possible. |

| G02/G03 (Circular Move) | These create arcs and circles. | Ensure your corner radii are standard and consistent to avoid complex toolpaths. |

| Tool Changes (M06) | Every tool change adds time and risk of error. | Design parts that can be made with the fewest unique tools possible. |

Learning these basics is like a designer learning the fundamentals of grammar. It helps you construct better "sentences" for the machine to read, resulting in a more elegant and efficient final product.

Is a CNC certificate worth it?

You’re a qualified engineer with a degree. You wonder if spending time and money on a CNC certificate will add any real value to your career. Without it, you might feel your knowledge is just theoretical, and you may lack the confidence to discuss manufacturing details authoritatively with suppliers.

For an engineer, a CNC certificate is less about getting a job as a machinist and more about validating your understanding of the manufacturing process. It’s definitely worth it. It provides a structured learning path, gives you hands-on experience, and serves as a credible signal to employers and manufacturing partners that you understand Design for Manufacturability (DFM) on a deep, practical level.

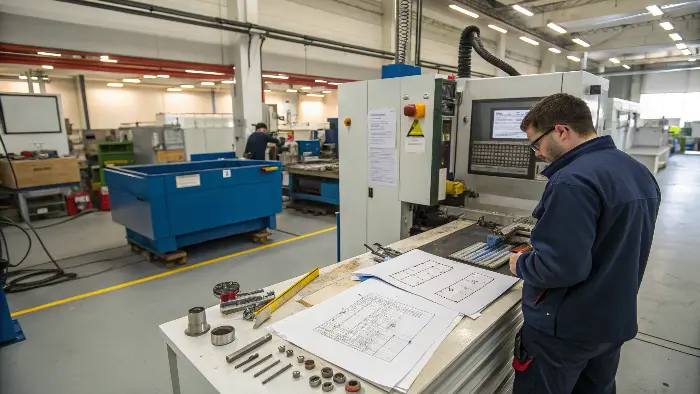

Let’s be clear: no one is going to hire a mechanical engineer to run a CNC machine just because they have a certificate. Your engineering degree is your primary qualification. However, the certificate serves a different, very important purpose. It’s about bridging the gap between theory and practice. I’ve seen engineers with certificates command more respect in discussions with shop floor managers. Why? Because it shows they’ve put in the effort to understand the machinist’s world.

Tangible Benefits of Certification for Engineers

The value isn’t just about feeling more confident. It translates into real-world benefits for your work. You learn the "why" behind the constraints you often hear about from suppliers. Why is a sharp internal corner a problem? Why does the material choice impact cycle time so much? A good certification program will have you physically set up a machine, run a program, and measure the results. This hands-on experience is something you can’t get from a textbook. It moves your knowledge from abstract to concrete.

What to Look for in a CNC Training Program

Not all certificates are created equal. If you’re an engineer like Alex looking to enhance your skills, find a program that focuses on:

| Feature | Importance | What to Avoid |

|---|---|---|

| Hands-On Machine Time | Crucial for understanding the physical process. | Theory-only or simulation-only courses. |

| CAM Software Training | Connects your CAD work to the machine. | Programs focused only on manual G-code writing. |

| DFM Principles | Directly applicable to your design work. | Courses aimed purely at operator speed and efficiency. |

| Metrology & Inspection | Teaches you how parts are verified for quality. | Programs that gloss over quality control. |

Think of it as a professional development course that directly impacts your core job. It makes you a more well-rounded, effective, and valuable engineer.

How long does it take to become a CNC engineer?

You’re interested in this path, but the idea of starting over and spending years in training seems daunting for an experienced professional. This hesitation might prevent you from gaining skills that could significantly advance your career and make your current job much easier.

The term "CNC engineer" can mean different things. If you’re an engineer wanting to become proficient in CNC principles, you can gain significant knowledge in a few months of focused study. To become a manufacturing engineer specializing in CNC might take 1-2 years of combined experience. To become a master-level machinist from scratch takes many years.

This question is tricky because the destination is different for everyone. For an engineer like Alex, the goal isn’t to become a full-time CNC programmer. The goal is to become an engineer who understands CNC deeply. This is a much more achievable and targeted path. I’ve worked with many engineers who have successfully integrated this knowledge into their roles, making them far more effective.

A Realistic Timeline for an Engineer

Let’s break down what a practical learning path could look like for a busy design engineer. This isn’t about a career change; it’s about skill enhancement.

| Stage | Duration | Activities & Goals |

|---|---|---|

| 1. Foundational Knowledge | 1-2 Months | Online courses, reading books. Goal: Understand terminology, machine types, basic G-code, and DFM principles. |

| 2. Practical Application | 3-6 Months | A part-time certificate course, using CAM software (like Fusion 360) for personal projects, visiting machine shops. Goal: Connect theory to practice. |

| 3. Integration & Mastery | Ongoing | Actively applying DFM in your job, having deeper conversations with suppliers, asking "why" about manufacturing feedback. Goal: Make CNC knowledge an intuitive part of your design process. |

As you can see, you can become highly effective in just a few months. You’re not starting from zero. You already have the engineering foundation—the math, the physics, the material science. You’re just adding the manufacturing context. I started on the shop floor, so I learned the practical side first. Engineers often learn the theory first. The magic happens when you meet in the middle. For an engineer, that journey to the middle is much shorter than you think.

Conclusion

Ultimately, CNC training makes you a better engineer. It closes the gap between your design and the final part. You’ll create more manufacturable designs, communicate more effectively with suppliers, and deliver projects faster and with fewer issues. It’s a powerful investment in your professional skills.