You’ve perfected your aluminum part design, but now you face a critical choice. Should you CNC machine it, extrude it, or die cast it? Choosing the wrong manufacturing process can lead to massive budget overruns, missed deadlines, and a part that fails to meet your expectations.

To choose the right aluminum manufacturing process, match the method to your part’s complexity and production volume. Use CNC machining for low-to-mid volumes (1-10,000) and complex parts. Choose extrusion for high volumes of parts with a constant cross-section. Select die casting for very high volumes (50,000+) of complex shapes where low per-part cost is critical.

I’ve seen this happen many times. A brilliant engineer like Alex designs a fantastic component, but they default to the process they know best, not the one that’s most efficient for the job. A process that’s perfect for a single prototype is often a terrible choice for mass production. Understanding the trade-offs between volume, complexity, and cost is one of the most valuable skills a product developer can have. Let’s walk through the main options so you can make the right call.

When is CNC Machining the Best Choice for Aluminum Parts?

You need a handful of high-precision parts for a prototype, and you need them fast. The thought of paying tens of thousands for a mold for just ten parts is terrifying. How do you get complex, functional aluminum parts without a huge upfront investment?

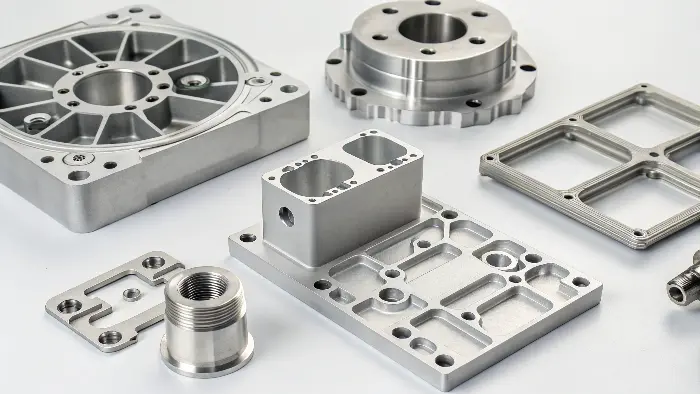

CNC machining is the best choice for low-to-mid volume production, from a single prototype up to around 10,000 units. It offers incredible design freedom for complex geometries, achieves very tight tolerances, and requires no tooling investment. This makes it ideal for rapid prototyping, custom fixtures, and initial production runs where speed and flexibility are key.

CNC machining is the heart of our business at QuickCNCs, and for good reason. It’s the most versatile process for creating custom aluminum parts. I remember working with a robotics startup that needed to test three different gripper designs. They needed them to be strong and precise. With CNC machining, we were able to deliver all three functional prototypes, made from 6061 aluminum, in just over a week. If they had chosen a process with tooling, they would have spent months and a huge amount of money before ever testing their first idea.

Breaking Down CNC Machining

CNC (Computer Numerical Control) machining is a subtractive process. We start with a solid block of aluminum and use computer-controlled cutting tools to remove material until only the final part remains.

- Complexity and Precision: This is where CNC shines. 5-axis machines can create incredibly complex shapes, undercuts, and intricate features that are impossible with other methods. For an engineer like Alex developing high-tolerance robotic joints, achieving tolerances of ±0.01mm is standard work for CNC.

- Volume and Speed: It’s the fastest way to get from a digital design to a physical part in your hands, especially for small quantities. While the per-part cost is higher than mass production methods, the absence of tooling costs makes it the most economical choice for volumes under a few thousand pieces.

- Material Choice: You can machine almost any aluminum alloy, from the common 6061 to the high-strength 7075. This gives you the freedom to test your design with the exact end-use material.

The trade-off is that the cost per part doesn’t decrease as dramatically with volume compared to molding or casting. Each part takes a certain amount of machine time, so making 10,000 parts takes roughly 10,000 times longer than making one.

Should You Consider Aluminum Extrusion for Your Design?

Your part is long and has the same shape from one end to the other, like a rail, a tube, or a window frame. You need thousands of meters of it, and the cost needs to be as low as possible. Machining each one from a solid block would be incredibly wasteful and expensive.

You should consider aluminum extrusion for high-volume production of parts that have a constant two-dimensional profile. The process involves pushing a heated aluminum billet through a steel die to create long, continuous shapes. While there is a moderate upfront tooling (die) cost, the resulting per-part cost is very low, making it highly efficient for the right kind of geometry.

Think of squeezing toothpaste from a tube; the shape of the opening determines the shape of the toothpaste stream. Extrusion works on the same principle. It’s a fantastic process for creating parts that are defined by their cross-section. I once worked on a project for an LED lighting company. They needed custom heat sinks. The profile was complex, with many thin fins, but it was the same along its entire 2-meter length. Extrusion was the perfect solution. We created one die, and they could then order thousands of meters of the heat sink at a very low cost, simply cutting it to the length they needed.

Understanding Extrusion’s Strengths and Weaknesses

This process is a great example of designing for manufacturability. If you can design your part to have a constant profile, you can unlock huge cost savings.

- Ideal Geometries: Perfect for parts like T-slots, heat sinks, enclosures, frames, and custom tubing. The parts come out in long lengths and are then cut to size. Secondary machining operations can be added to drill holes or tap threads.

- Cost Structure: There’s an initial cost for the steel die, typically a few thousand dollars. But once that’s paid, the cost per meter of the extruded aluminum is very low. This makes it economical for production runs of several hundred kilograms or more.

- Limitations: The biggest limitation is that the part’s cross-section must be uniform along its length. You cannot create features that stick out from the side or have varying wall thicknesses along the length of the part with extrusion alone. Alloys like 6063 and 6061 are most common due to their excellent extrudability.

Is Die Casting the Right Process for High-Volume Aluminum Production?

You’re launching a product that you expect to sell by the hundreds of thousands. The part has a complex, three-dimensional shape, like a car’s transmission housing or a power tool’s body. Every penny saved on the per-part cost matters. Is there a process that can handle this scale?

Die casting is the right process for mass-producing complex aluminum parts in volumes of 50,000 units or more. It involves injecting molten aluminum into a hardened steel mold (a die) under high pressure. The initial tooling cost is very high, but it results in the lowest possible per-part cost and extremely fast cycle times, making it the king of high-volume manufacturing.

When you need to scale up to true mass production, die casting is often the only logical choice. The upfront investment is significant—a complex steel die can cost anywhere from $20,000 to over $100,000. This scares many people away. But if you have the volume to justify it, the economics are unbeatable. I consulted for a company making consumer-grade drones. The main body was a complex shell with many internal features. We calculated that the break-even point between CNC machining and die casting was around 20,000 units. Since they planned to sell 100,000 units in the first year, investing in a die casting mold saved them millions in the long run.

The Power and Pitfalls of Die Casting

This process is all about economy of scale.

- Complexity and Speed: Die casting can produce intricate, net-shape parts with fine details, meaning they often require little to no secondary machining. The cycle time is incredibly fast, with a new part being produced every minute or even every few seconds.

- Cost: The high tooling cost is the biggest barrier. But once that tool is made, the cost of each part is just the price of the raw material and the machine cycle, which is very low.

- Limitations: The high upfront cost and long lead time to create the tool (often several months) are major drawbacks. Design changes are also very difficult and expensive once the tool is made. Furthermore, not all aluminum alloys are suitable for casting, and parts can sometimes have internal porosity, which can be a concern for pressure-tight applications.

How Do You Compare the Costs and Lead Times of These Processes?

You understand the basics of CNC, extrusion, and die casting. But when it’s time to make a decision for your project, you need a clear, side-by-side comparison. How do you weigh the tooling cost against the part price and the lead time to get your first articles?

To compare these processes, create a decision matrix focused on your key variables: production volume, tooling cost, and lead time. CNC has zero tooling cost and the fastest lead time for initial parts. Extrusion has a moderate tooling cost and lead time. Die casting has a very high tooling cost and the longest lead time, but offers the lowest per-part cost at scale.

For an engineer like Alex, making this decision requires looking at the total project cost, not just the price of one part. It’s a strategic choice. I always advise my clients to map out their expected production volumes over the product’s life. A choice that seems expensive today might be the cheapest option a year from now. Let’s put the key decision factors into a simple table to make it clear.

Manufacturing Process Decision Matrix

| Factor | CNC Machining | Aluminum Extrusion | Aluminum Die Casting |

|---|---|---|---|

| Ideal Volume | 1 – 10,000 pieces | 1,000+ pieces (or hundreds of meters) | 50,000 – 1,000,000+ pieces |

| Tooling Cost | None | Moderate ($2,000 – $10,000) | Very High ($20,000 – $100,000+) |

| Per-Part Cost | High (at low volume), Medium (at mid-volume) | Very Low | Lowest |

| Initial Lead Time | Fastest (Days to 1-2 weeks) | Medium (4-8 weeks for die) | Slowest (8-20 weeks for mold) |

| Design Complexity | Very High (3D freedom) | Low (Constant 2D profile) | High (Complex 3D shapes) |

| Best For | Prototypes, custom parts, low-volume runs. | Frames, rails, heat sinks, linear parts. | Mass-produced complex parts, housings. |

Ultimately, the choice comes down to your specific situation. If you are still testing your design or need a small batch, CNC machining is the obvious winner. If your part has a simple, linear profile and you need thousands, extrusion is your answer. If you are confident in your design and are preparing for mass-market production, the investment in die casting will pay for itself many times over.

Conclusion

Choosing the right manufacturing process is as important as the design itself. By analyzing your part’s geometry, required precision, and especially your expected production volume, you can confidently select the most cost-effective method. CNC for flexibility, extrusion for profiles, and die casting for scale—mastering this choice is key.