Getting tolerances wrong causes headaches. Parts don’t fit, costs rise, and projects stall. Let’s make tolerance specification clearer for you.

Specify tight tolerances when parts must fit precisely, are safety-critical, or belong to complex assemblies. This improves fit and function. Avoid them for non-critical features to save cost and manufacturing time, as overly tight tolerances are expensive.

I’ve seen it countless times in my career at QuickCNCs: an engineer specifies an incredibly tight tolerance for a feature that, frankly, doesn’t need it. On the flip side, I’ve also seen designs where looser tolerances led to assembly problems down the line. It’s a balancing act. Tolerances are not just numbers on a drawing. They have real-world impacts on how a part functions, how much it costs, and how easy it is to make. Getting this right is a fundamental part of good engineering and manufacturing. So, when is "tight" truly necessary, and when is it just adding unnecessary cost and complexity? Let’s explore this.

What is considered a tight tolerance?

Engineers often talk about "tight" tolerances. But what does this really mean in practice? Understanding this term is the first step to using tolerances effectively.

A "tight tolerance" refers to a very small permissible range of variation for a part’s dimension. While context-dependent, values like ±0.005 inches (±0.127mm) or less are generally considered tight in CNC machining.

Defining "tight tolerance" can be a bit like asking "how long is a piece of string?" It really depends on the manufacturing process, the material, and the application. However, in my world of CNC machining, we do have some general benchmarks. When I see a drawing calling for a tolerance of ±0.005 inches (which is about ±0.127 millimeters), that’s a common starting point for what many consider "tight." If it goes down to ±0.001 inches (around ±0.025mm) or even tighter, like ±0.0005 inches (±0.0127mm), then we are definitely in the realm of very precise, and often more expensive, machining.

For perspective, a human hair is typically about 0.002 to 0.004 inches thick. So, a ±0.001 inch tolerance means the acceptable variation is less than the thickness of a human hair. Achieving this consistently requires skilled machinists, well-maintained machines, and often, special inspection equipment. It’s not something you specify lightly. The "tightness" is relative. For sheet metal work, ±0.020 inches might be considered tight, while for optics, tolerances could be in the nanometer range. At QuickCNCs, we handle a lot of requests where clients like Alex, the engineer from Germany, need these ±0.01mm accuracies for their robotic components. So, "tight" for us usually means getting into those sub-0.05mm zones.

Is ±0.005 inches a tight tolerance?

You see ±0.005 inches on a drawing. Is this a big deal for the machinist, or pretty standard? Knowing this helps you design for manufacturability.

Yes, ±0.005 inches (or ±0.127mm) is generally considered a tight tolerance in many CNC machining applications. Achieving it requires careful setup, good tooling, and often, more machining time, impacting cost.

So, let’s talk specifically about ±0.005 inches, or for our metric friends, approximately ±0.127 millimeters. In my experience, yes, this is where tolerances start to be considered "tight" for general CNC machining of metals and many plastics. It’s not an extreme tolerance that requires super-specialized processes for many common part geometries, but it does demand a higher level of care and control than, say, ±0.015 inches or ±0.030 inches.

Achieving a ±0.005 inch tolerance reliably means the machinist needs to be on their game. Machine tool accuracy and rigidity become more important. The quality and sharpness of cutting tools matter more. Temperature fluctuations in the shop can even start to play a role if the material has a high coefficient of thermal expansion. It often means slower feed rates or extra finishing passes. All these factors add to the time and, therefore, the cost of producing the part.

For some applications, like simple brackets or non-critical covers, ±0.005 inches might be unnecessarily restrictive. For others, like certain bearing fits or alignment features, it could be perfectly appropriate or even a bit loose. My insight, based on working with hundreds of clients like Alex who design precision components, is that if a feature is intended to mate closely with another part, or if its dimensional accuracy directly affects the performance or safety of the final product, then ±0.005 inches is a reasonable "tight" tolerance to consider. However, if it’s just a clearance hole or the overall size of a non-interfacing feature, you can often save money by specifying something looser.

What is the purpose of tight tolerance ranges?

Why do engineers even bother with these tiny numbers? There must be good reasons to demand such precision. Understanding the purpose helps justify the cost.

Tight tolerance ranges ensure parts fit together correctly, function as intended, and are interchangeable. They are critical for safety, performance in demanding applications, and assemblies requiring precise alignment or movement.

The fundamental purpose of specifying any tolerance is to define an acceptable range of variation for a dimension. When we make that range tight, we’re doing it for very specific, important reasons. I’ve seen firsthand how the right tolerances can make or break a project. The primary goals are usually centered around fit, function, and interchangeability.

For fit, think about parts that need to assemble perfectly. A shaft going into a bearing, for example. If the shaft diameter tolerance is too loose, it might be too tight to fit, or too loose and wobble. A tight tolerance here ensures a precise press fit or running clearance. This is something Alex, our engineer designing robotic joints, deals with daily. He needs exact fits for smooth, backlash-free movement.

For function, consider high-performance applications. In an engine, the clearance between a piston and cylinder is critical. Too much, and you lose compression and power. Too little, and it seizes. Tight tolerances ensure the component performs its job optimally and reliably. Safety-critical parts, like those in aircraft or medical devices, almost always require tight tolerances because their precise function is directly linked to safety.

Interchangeability is another key purpose. If you’re mass-producing a product, you want any "Part A" to fit with any "Part B" off the assembly line, without hand-fitting. Tight, consistent tolerances make this possible. This simplifies assembly, repairs, and spare parts management. At QuickCNCs, when we machine multiple identical parts for a client, maintaining tight tolerances across the batch is essential for this reason. So, while tight tolerances add cost, their purpose is to deliver a higher level of precision that translates into better product performance, reliability, and often, safety.

How do you specify tolerances on a drawing?

You know you need a tolerance. But how do you actually communicate this clearly to the machinist? Proper notation is key to getting the part you expect.

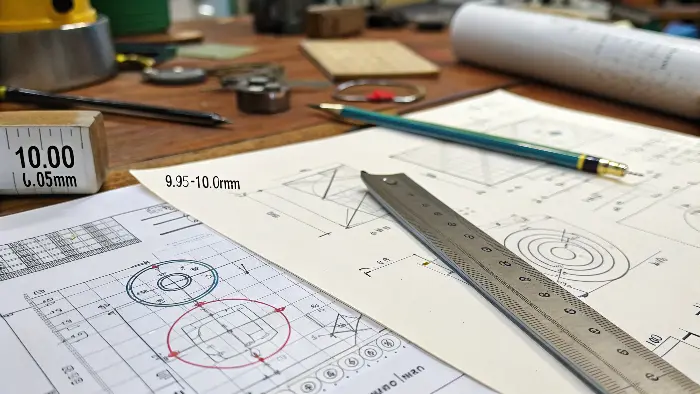

Tolerances are specified on engineering drawings using various methods. These include plus/minus values (e.g., 10.00 ±0.05mm), limit dimensions (e.g., 9.95-10.05mm), geometric dimensioning and tolerancing (GD&T), or general tolerance notes.

Communicating your tolerance requirements clearly is absolutely vital. An ambiguous or poorly specified tolerance can lead to misinterpretations, incorrect parts, and wasted time and money. As someone who reads and works from engineering drawings every day at QuickCNCs, I can’t stress this enough. There are several standard ways to do this:

- Plus and Minus Tolerancing (Bilateral or Unilateral): This is very common.

- Bilateral: The variation is allowed in both directions from the nominal dimension. For example,

1.000 ±0.005 inchesmeans the part can be anywhere from 0.995 to 1.005 inches. - Unilateral: The variation is allowed in only one direction. For example,

1.000 +0.010 / -0.000 inchesmeans the part can be from 1.000 to 1.010 inches, but not smaller than 1.000.

- Bilateral: The variation is allowed in both directions from the nominal dimension. For example,

- Limit Dimensions: This method states the maximum and minimum allowable sizes directly. For example,

0.995 - 1.005 inches. This is very clear and leaves no room for calculation errors by the machinist. - General Tolerance Notes: Drawings often include a title block note specifying default tolerances for dimensions that don’t have a specific tolerance callout. For example, "ALL UNTOLERANCED DIMENSIONS ±0.010 INCHES" or based on the number of decimal places (e.g., X.X = ±0.03, X.XX = ±0.01, X.XXX = ±0.005). It’s crucial to check these notes.

- Geometric Dimensioning and Tolerancing (GD&T): This is a more advanced and comprehensive system. GD&T uses symbols to define tolerances for form (flatness, straightness), orientation (perpendicularity, parallelism), location (position), and runout. It’s incredibly powerful for controlling complex geometric relationships, especially for parts like those Alex designs for robotic systems. GD&T can actually help loosen some dimensional tolerances while still ensuring perfect function by controlling the critical geometric aspects.

When I review a drawing, I look for clarity. The best approach often combines these methods. Use specific plus/minus or limit dimensions for critical features, and rely on GD&T for complex relationships. Clear specification is the foundation of a successful manufacturing partnership.Conclusion

Specifying tolerances wisely is crucial. Use tight tolerances for critical fits and functions. Otherwise, looser tolerances save cost and time, ensuring efficient manufacturing.