Assembly headaches? Parts not staying put? Choosing the wrong joining method causes failures and rework. Discover if press fit or shrink fit is your assembly solution.

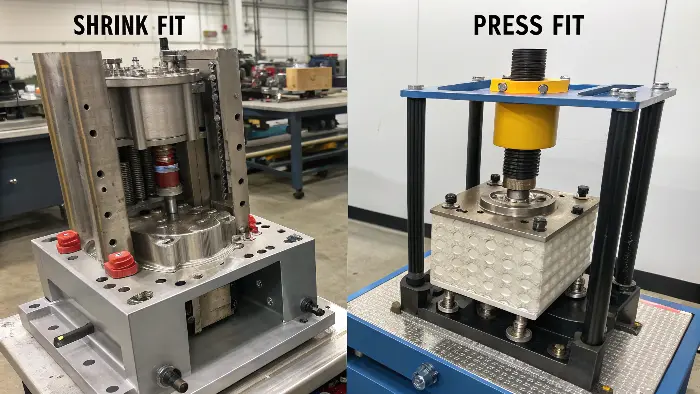

Press fits and shrink fits are both interference fits. They join parts by forcing one into another. Press fits use mechanical force. Shrink fits use temperature changes for assembly. The choice depends on materials, precision, and assembly ease.

Selecting the best way to join two parts is very important in engineering. I have seen many projects succeed or fail based on this choice. Both press fits and shrink fits create strong connections. But they work differently. Understanding these differences helps you design better products. It also helps us at QuickCNCs machine your parts perfectly for the chosen assembly method. Let us look closer at these common techniques.

What Are the Different Types of Fit and When Would Each Be Most Important to Assess?

Confused by fits? Clearance, transition, interference – what’s what? Wrong fit means wobbly parts or impossible assembly. Understand fit types to ensure your components function perfectly.

Fits describe how parts join. Clearance fits allow movement. Interference fits create tight bonds. Transition fits are in between. Assess them based on required movement or holding power.

When we talk about how two parts, like a shaft and a hole, go together, we are talking about "fit." It is a basic idea in mechanical engineering. I often explain this to engineers like Alex when we discuss tolerances for their CNC machined parts. There are generally three main categories of fits. Understanding these is the first step. It helps decide if something like a press fit or shrink fit is even needed.

Main Categories of Fits:

| Fit Type | Description | Typical Use Case Example | When to Assess Importance |

|---|---|---|---|

| Clearance Fit | The shaft is always smaller than the hole. This allows free movement. | A shaft rotating freely in a plain bearing. | When parts need to move relative to each other. |

| Interference Fit | The shaft is always larger than the hole before assembly. Force is needed. | A bearing pressed into a housing. A gear on a shaft. | When a strong, permanent joint is needed. |

| Transition Fit | The shaft might be slightly smaller or slightly larger than the hole. | Locating pins, some couplings. | When precise location is needed without force. |

Each type has its place. For example, Alex might need a clearance fit for a robotic joint that needs to pivot smoothly. But for mounting a motor pinion gear, he would definitely need an interference fit. The ISO system of limits and fits (like H7/g6 for clearance, or H7/p6 for interference) gives us standard ways to define these. This ensures parts from different places can still assemble correctly. The key is to define the function first. Then, choose the fit.

What Is the Difference Between a Press Fit and an Interference Fit?

Press fit? Interference fit? Are they the same? Terminology confusion leads to design miscommunication.

An interference fit is the general term. It means the shaft is larger than the hole. A press fit is one specific method to achieve this tight assembly using mechanical force.

This is a common point of confusion. I want to make it clear. An "interference fit" is a condition. It describes the situation where the male part (like a shaft) is intentionally made slightly larger than the female part (like a hole) it is meant to mate with. You cannot just slide them together. Force is required. Now, "press fit" is one of the methods to achieve this interference fit. It specifically refers to using mechanical force at room temperature to push the parts together. Think of using an arbor press or a hydraulic press. So, all press fits are interference fits. But not all interference fits are achieved by pressing. A shrink fit, for example, is also an interference fit. But it uses a different method. I remember a project where a drawing just said "interference fit." We had to ask the client, "Do you mean a press fit, or are you planning to use shrink fitting?" Clarifying this early on saved a lot of trouble. Knowing the intended assembly method helps us at QuickCNCs to suggest the right surface finish and tolerances on the parts. For a press fit, a slightly rougher finish can sometimes help with grip, while for a shrink fit, smoother surfaces might be preferred to avoid galling during assembly.

What Is the Difference Between Shrink Fit and Press Fit?

Choosing between press and shrink fit? It’s tricky. The wrong choice means damaged parts or weak joints.

Press fit uses mechanical force. Shrink fit uses temperature. The outer part is heated to expand, or the inner part is cooled to shrink, for easy assembly. They cool/warm to create a strong interference.

This is the main question many engineers face. Both press fits and shrink fits aim to create a strong, solid joint by making the shaft larger than the hole. The big difference is how they achieve that assembly.

A press fit uses brute force, but controlled force. We use tools like an arbor press for smaller parts or a hydraulic press for larger ones. The parts are at room temperature. We literally press the shaft into the hole. I have done this many times in the shop. It requires careful alignment. It can sometimes cause a bit of scoring or material displacement if not done right, or if the interference is too large.

A shrink fit is more about clever use of physics. We change the temperature of one or both parts.

- Usually, we heat the outer part (the hole). Metal expands when heated. The hole gets temporarily larger.

- Or, we cool the inner part (the shaft), often with liquid nitrogen. Metal shrinks when cooled. The shaft gets temporarily smaller.

Then, we can easily slip the parts together. Once they return to the same temperature, the outer part shrinks back down, and the inner part expands back up. This creates a very strong, uniform pressure between them. Alex once had a delicate sensor housing. We recommended a shrink fit for inserting a hardened steel bushing. A press fit might have distorted the housing. The shrink fit worked perfectly. It applied even pressure all around.Key Differences Summarized:

Feature Press Fit Shrink Fit Force Applied Mechanical (press) Thermal (expansion/contraction) Temperature Ambient temperature One part heated, or one part cooled, or both Process Direct forcing of parts Temperature change allows easy assembly, then grip Stress on Parts Can be higher, localized at entry Generally more uniform stress distribution Equipment Arbor press, hydraulic press Oven, induction heater, liquid nitrogen The choice depends on materials, part geometry, the amount of interference needed, and the equipment available.

What Is the Difference Between Press Fit and Slip Fit?

Parts too loose or too tight? Slip vs. press fit. Not understanding this difference leads to assembly failure.

Press fits create a tight, fixed assembly using force. The shaft is bigger than the hole. Slip fits have clearance. The shaft is smaller, allowing easy movement or disassembly.

Press fits and slip fits are really opposites in terms of how parts interact. A "slip fit" is a type of clearance fit. This means the shaft is intentionally made smaller than the hole. You can literally slip the shaft into the hole easily by hand. There is a gap, or clearance, between them. This is what you want if parts need to move freely relative to each other, like a pin in a clevis that needs to rotate, or a shaft that needs to slide in a bushing. I often see slip fits used for locating parts that will be fastened by other means, like bolts. The slip fit helps get them aligned easily before tightening.

A press fit, as we have discussed, is an interference fit. The shaft is larger than the hole. You cannot just slip it in. You need significant force. The goal of a press fit is to create a strong, semi-permanent or permanent joint that can transmit torque or resist axial forces without keys, pins, or adhesives. When Alex designs components for his robotic arms, he uses press fits for things like bearings in housings or dowel pins for precise alignment where no movement is wanted after assembly. The key difference is intent: slip fits are for movement or easy assembly/disassembly. Press fits are for creating a strong, fixed connection. Trying to use a slip fit where a press fit is needed will lead to a loose, wobbly assembly. Trying to force a press fit where a slip fit was designed could damage the parts or make assembly impossible.Quick Comparison:

Feature Press Fit Slip Fit (Clearance Fit) Shaft vs. Hole Shaft is larger than hole Shaft is smaller than hole Assembly Requires force (mechanical press) Easy, by hand, no force needed Resulting Joint Tight, fixed, transmits load Loose, allows relative movement Purpose Secure joining, load transmission Free movement, easy assembly/location Understanding this basic difference is fundamental to good mechanical design.

Conclusion

Press fits use force, shrink fits use temperature. Both create strong interference joints. Choosing depends on material, precision, and assembly. This ensures your parts join securely and function correctly.