Struggling with CNC tolerances? Incorrect specs cause costly reworks. Learn how to design parts right for manufacturing.

To design parts with proper CNC tolerances, consider function, machine capabilities, and material. Avoid overly tight tolerances. Understand material behavior and use correct GD&T specifications. This ensures manufacturability and cost-effectiveness.

Getting tolerances right is crucial. It is a balance between what you need and what is practical to make. I have seen many designs, and the best ones always consider manufacturing early. This approach helps you avoid common pitfalls. It also helps you achieve the precision your project needs. Let us explore this more.

What Exactly Are Tolerances in CNC Manufacturing?

Confused by CNC tolerance talk? Vague numbers can lead to failed parts. Let us clarify what these crucial limits mean.

CNC manufacturing tolerances are the acceptable deviations from a specified dimension. They define the permissible range for a part’s features. This ensures it functions correctly within an assembly.

When we talk about tolerances in CNC manufacturing, we are discussing the small variations allowed in a part’s size or geometry. No machine can make a part exactly to the nominal dimension every single time. So, designers specify a range. For example, if a shaft needs to be 10mm in diameter, a tolerance might be ±0.05mm. This means any shaft between 9.95mm and 10.05mm is acceptable. These limits are vital. They ensure parts fit together. They also ensure parts perform as intended. Different CNC processes, like milling or turning, have different inherent accuracies. Even the machine’s condition and the cutting tools used play a role. I always tell clients, "Think about how much ‘wiggle room’ your part really needs." Tighter tolerances often mean higher costs. So, it is about finding that sweet spot between precision and practicality.

Key Types of Tolerances

There are a few main types of tolerances you will encounter:

- Dimensional Tolerances: These relate to the size of features. This includes length, width, height, diameter, and thickness. They are usually expressed as a permissible range (e.g., 10mm ±0.1mm) or as limit dimensions (e.g., 9.9mm to 10.1mm).

- Geometric Tolerances (GD&T): These control the shape, profile, orientation, location, and runout of features. Examples include flatness, straightness, perpendicularity, parallelism, position, and concentricity. GD&T provides a more precise way to define functional requirements than dimensional tolerances alone. I have seen many engineers, like Alex, use GD&T effectively to ensure complex parts assemble correctly.

Understanding these helps you communicate your design intent clearly.What is a Typical Fabrication Tolerance We See in CNC Machining?

Wondering about standard precision? Unrealistic expectations can delay projects. Let us look at common fabrication tolerance ranges you can expect.

A typical fabrication tolerance for general CNC machining is often around ±0.1mm (±0.004 inches). For precision work, ±0.025mm (±0.001 inches) is common. Tighter is possible with specialized processes and more cost.

The term "typical fabrication tolerance" can vary quite a bit. For many general-purpose CNC machined parts, something like ±0.1mm (or about ±0.004 inches) is a good baseline. This is often achievable without special setups or extra costs. However, many applications, especially like the robotics components Alex designs, need tighter control. In those cases, we often see tolerances like ±0.025mm (±0.001 inches) or even ±0.01mm. Going tighter than ±0.01mm is possible. But it usually means more specialized machines and slower machining times. It also means more careful inspection, and thus, higher costs. I remember a project for a medical device company. They needed ±0.005mm on a critical bore. We achieved it. But it required specific tooling, a climate-controlled environment for the final passes, and multiple inspection stages. So, "typical" depends heavily on the application. It also depends on what is truly necessary for the part to function. Always discuss your needs with your machinist.Feature Type General Tolerance (± mm) Precision Tolerance (± mm) High Precision (± mm) Notes Diameters (turned) 0.1 0.025 0.01 Tighter for reamed/ground holes Lengths/Widths (milled) 0.125 0.05 0.02 Depends on part size and material stability Hole Positions 0.1 0.025 0.01 Relative to datums Flatness/Parallelism 0.1 per 100mm 0.025 per 100mm Varies Highly dependent on geometry and setup Angles 0.5° 0.1° 0.05° Check with your supplier for very tight angles This table provides a general idea. Specific capabilities can vary between shops and machines.

How Do We Actually Determine Tolerances in the Manufacturing Process?

Curious about how tolerance values are set? Guesswork leads to problems. Understand the factors influencing these crucial manufacturing decisions.

Tolerances are determined by the part’s functional requirements. The chosen manufacturing process capabilities, material properties, and cost considerations also play a role. It is a balance between design intent and practical producibility.

Determining tolerances is a critical step. It is a collaborative effort between design and manufacturing. First, the designer, like Alex, defines what the part needs to do. This is the functional requirement. How does it fit with other parts? What loads does it bear? Does it need to seal? These questions guide the initial tolerance ideas. Then, we in manufacturing look at our process capabilities. What can our CNC machines reliably achieve for a given material? Some materials, like certain plastics, are harder to hold tight tolerances on than stable metals like steel. Material stability, thermal expansion, and machinability all play a role. I have seen cases where a designer specified a very tight tolerance on a long, thin aluminum part. Aluminum expands and contracts significantly with temperature changes. This makes that tolerance very challenging and expensive to hold consistently during machining and inspection. We also consider the cost. Tighter tolerances almost always mean higher costs. This is due to slower machining, more tool wear, higher scrap rates, and more intensive inspection. So, we determine tolerances by balancing all these factors: function, process, material, and cost. A good discussion can often find a more manufacturable solution.Factors Influencing Tolerance Determination:

- Functional Fit: How parts assemble (clearance, interference, transition fits).

- Machine Capability: The inherent precision of the CNC machine and tooling.

- Material Properties: Stability, hardness, machinability, thermal expansion.

- Measurement Capability: Ability to accurately inspect the specified tolerance.

- Cost: Tighter tolerances usually increase machining time, tooling wear, and inspection effort.

- Production Volume: For high volumes, optimizing for slightly looser (but still functional) tolerances can save significantly.

So, How Should You Design Parts Specifically for CNC Manufacturing with Tolerances in Mind?

Want to optimize your CNC designs? Poorly planned parts increase costs. Learn key strategies for effective CNC part design.

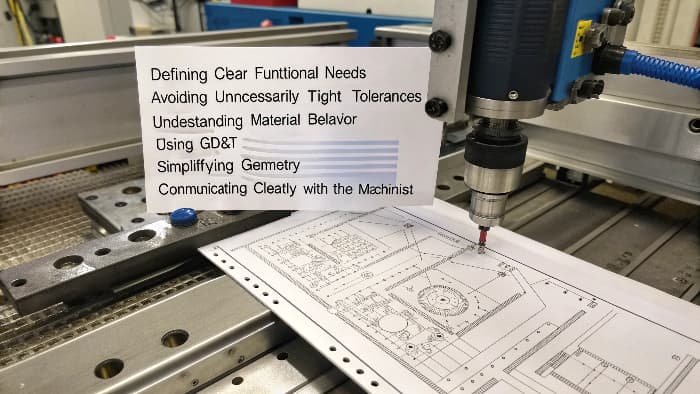

Design for CNC by defining clear functional needs. Avoid unnecessarily tight tolerances. Understand material behavior and use GD&T. Simplify geometry where possible and communicate clearly with your machinist.

Designing parts effectively for CNC manufacturing, especially concerning tolerances, involves several key strategies. Based on my experience helping clients like Alex, here is what I always emphasize.

First, clearly define the functional requirements. What does this part actually need to achieve? This will guide which tolerances are critical and which can be looser. Not every surface needs extreme precision.

Second, avoid unnecessarily tight tolerances. This is a big one. I have seen drawings where every dimension has a super tight tolerance, even on non-critical features. This drives up cost and lead time significantly. If a feature does not need to be precise, use a standard or general tolerance. Often, a shop’s standard tolerance (e.g., ISO 2768-mK) is sufficient for many features.

Third, understand material properties. How will the material behave during and after machining? Consider thermal expansion, stability, and hardness. For instance, machining Delrin (POM) to a tight tolerance is very different from machining stainless steel 304. Some plastics might warp or creep after machining.

Fourth, use Geometric Dimensioning and Tolerancing (GD&T) correctly. GD&T is a powerful language. It defines not just size but also form, orientation, and location of features. Use it wisely to control what truly matters. For example, specifying parallelism between two surfaces might be more important than their exact distance apart for a specific function.

Fifth, simplify geometry if possible. Complex shapes and very small features can be harder and more expensive to machine accurately. Consider if internal sharp corners are truly needed or if a small radius (from the cutting tool) is acceptable.

Finally, communicate with your manufacturer. Discuss your design and critical tolerances early. We can often provide feedback on manufacturability and suggest cost-saving adjustments. A quick chat can save a lot of headaches later.Practical Design Tips for CNC Tolerances:

- Datum Selection: Choose stable and accessible datum features. These are the reference points for all your critical dimensions and GD&T callouts.

- Standard Tolerances: For non-critical features, specify general tolerances (e.g., ISO 2768-m or a company standard). This reduces drawing clutter and manufacturing cost.

- Material Choice Matters: Select materials that can hold the required tolerances. Some materials are inherently more stable and easier to machine precisely.

- Consider Machining Process: Think about how the part will be made. Will features be milled, turned, drilled, or ground? Each process has its own tolerance capabilities.

- Surface Finish: Specify surface finish requirements only where needed. A very smooth finish often requires additional processing steps and can influence dimensional accuracy.

By keeping these points in mind, you can design parts that are not only functional but also cost-effective to manufacture.Conclusion

Designing with proper CNC tolerances means balancing function, material, and process. Clear specifications ensure quality parts without overspending or delays.