Are you struggling with high tool wear and inconsistent quality in your grooving operations? These issues can quickly eat into your profits, especially in high-volume production. Finding a strategy that balances speed, precision, and cost feels like an impossible task, leading to production delays and budget overruns.

The key to cost-effective, high-volume grooving is a systems approach. This means carefully selecting the right grooving type, using application-specific tooling, and optimizing cutting parameters like feed, speed, and depth. For mass production, choosing durable coated carbide inserts and a rigid tool-holding system is critical to minimizing tool changes and ensuring consistent part quality, which directly lowers the cost per part.

Mastering grooving is about more than just cutting a channel into a part. It’s a precise science that has a huge impact on the final product’s functionality and your bottom line. I’ve seen many projects get bogged down by inefficient grooving processes. The good news is that with the right knowledge, you can turn this common bottleneck into a streamlined, profitable part of your production line. Let’s break down the essential elements to help you achieve just that.

What Exactly Is the Grooving Process in CNC Machining?

Facing a design with O-ring seats or clearance channels? The grooving process seems straightforward, but a poor approach leads to chatter, bad surface finish, and broken tools. This can halt your production line and create a pile of expensive scrap material, a nightmare for any project manager.

In CNC machining, grooving is the process of cutting a narrow channel or recess into a workpiece. This is typically done on a lathe for cylindrical parts or a mill for flat surfaces. A specialized grooving tool is fed radially or axially into the material to create features like O-ring grooves, circlip grooves, undercuts for thread relief, and decorative channels, all with specific depths and widths.

Understanding the fundamentals of the grooving process is the first step toward optimizing it. It’s not just about removing material; it’s about creating a very specific geometric feature that is often critical for the assembly’s function. In my early days, I learned the hard way that treating a grooving operation like a simple turning cut is a recipe for disaster. The forces involved are different, chip control is more challenging, and the tool’s geometry is far more specialized. Whether the groove is on the outside diameter, the inside diameter, or the face of a part, the core principles remain the same: precision, stability, and controlled material removal. Getting these fundamentals right sets the foundation for a successful and repeatable high-volume production run.

The Phases of a Grooving Cut

A grooving operation looks simple, but it’s a sequence of controlled movements. Breaking it down helps troubleshoot issues and optimize performance.

- Plunging: This is the primary cutting phase. The tool feeds directly into the workpiece to the required depth. For wider grooves, this may involve multiple plunge cuts side-by-side, often called "pecking."

- Turning (for Wide Grooves): After the initial plunge, the tool may be fed axially (sideways) to widen the groove to its final dimension. This turning phase requires a tool designed for side-turning to avoid excessive tool pressure and chatter.

- Finishing: A final, light pass may be taken to ensure the groove’s walls and bottom have the desired surface finish and dimensional accuracy.

- Retraction: The tool is carefully withdrawn from the groove.

Grooving vs. Parting-Off

While they use similar tools and principles, grooving and parting-off have different goals.

| Feature | Grooving Operation | Parting-Off Operation |

|---|---|---|

| Primary Goal | Create a specific channel or recess in a part. | Cut a finished workpiece completely off the bar stock. |

| Cut Depth | Limited to the specified groove depth. | Cuts through the entire diameter to the center of the part. |

| Tool Path | Plunge in, possibly turn, and retract. | Plunge directly to the center and retract. |

| Key Challenge | Achieving correct width, depth, and surface finish. | Preventing the part from "pipping" or breaking off poorly. |

Understanding this distinction is crucial. I once worked with a client who was using a standard grooving insert for a deep parting operation. They were breaking inserts constantly. We switched them to a dedicated parting blade with a stronger geometry and proper chip-forming features, and their tool life increased tenfold.

What Are the Different Types of Grooving Operations?

Does your project require an internal groove for a seal and an external one for a clip? Using the same approach for both can lead to poor results. Different groove locations and forms demand unique tools and strategies, and a mismatch can cause tool failure or parts that don’t meet spec.

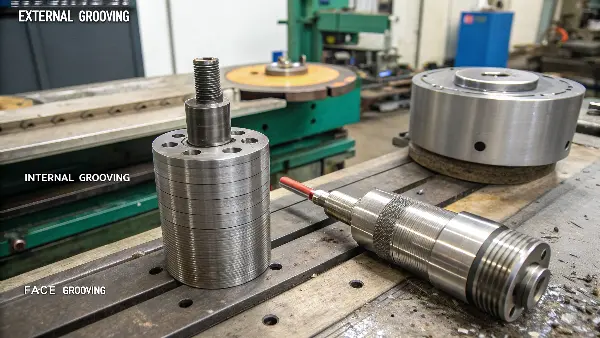

Grooving operations are categorized primarily by their location on the workpiece. The main types include external grooving on the outer diameter, internal grooving inside a bore, and face grooving on the front surface of the part. Each type presents unique challenges related to tool access, rigidity, and chip evacuation, requiring a specific setup.

Choosing the right type of operation is dictated by your design. I remember helping an engineer in Germany, Alex, who was designing a complex hydraulic manifold. His initial drawings had an internal groove that was almost impossible to machine due to its depth and the small bore diameter. The tool overhang would have been massive, guaranteeing chatter. By working together, we slightly modified the design to use a face groove and an external seal, which was far easier and more reliable to produce in high volume. This simple change saved the project from significant delays and costs. Understanding these different types isn’t just for machinists; it’s essential for designers to create manufacturable parts.

A Breakdown of Grooving Types

Let’s dive deeper into the common types of grooving. Each has its own application and set of challenges that you need to be aware of during the design and manufacturing planning stages.

External Grooving

This is the most common type. The tool cuts a groove on the outside diameter of a cylindrical part.

- Application: O-ring seats, circlip grooves, relief for subsequent grinding or threading operations.

- Challenge: Ensuring the groove bottom is perfectly parallel to the part’s axis. Tool rigidity is high, so chip control is the main focus.

Internal Grooving (Bore Grooving)

Here, the tool enters a pre-drilled hole to cut a groove on the inside diameter.

- Application: Internal circlip grooves, oil passages, and internal seals.

- Challenge: This is much more difficult. Tool access is limited, overhang is significant (leading to vibration), and chip evacuation is a major problem. Chips can get packed in the bore, break the tool, or ruin the surface finish.

Face Grooving

The tool cuts a circular groove on the face of a workpiece, like cutting a ring on a flat surface.

- Application: Sealing surfaces on flanges, connectors, and thrust bearings.

- Challenge: Maintaining a constant cutting speed. As the tool moves from a large diameter to a small one, the surface speed changes dramatically. CNC lathes use "Constant Surface Speed" (CSS) mode to adjust the RPM automatically, ensuring a consistent finish.

The table below summarizes the key considerations for each type.

| Grooving Type | Main Challenge | Key to Success |

|---|---|---|

| External | Chip Control | Proper chip-breaker geometry on the insert. |

| Internal | Rigidity & Chip Flow | Shortest possible tool overhang, through-coolant. |

| Face | Varying Surface Speed | Using the CNC’s Constant Surface Speed (CSS) function. |

What Are the Most Critical Factors for Successful Grooving and Parting?

Have you ever had a batch of parts fail inspection due to inconsistent groove depth or a poor surface finish? When you’re running thousands of parts, even small deviations add up to big losses. These problems often stem from overlooking a few fundamental factors in your setup and programming.

The most critical factors for success are rigidity, chip control, and heat management. A rigid setup (machine, tool holder, and workpiece) prevents vibration. Efficient chip control stops chips from getting jammed and ruining the part or tool. Finally, managing heat with the correct coolant application and cutting parameters ensures dimensional stability and extends tool life.

I can’t stress rigidity enough. Think of it as the foundation of your house; if it’s weak, everything else will fail. I once visited a shop struggling with a high-volume parting operation. Their tools were failing prematurely. The problem wasn’t the tool itself, but a worn-out turret on their CNC lathe that had a tiny bit of play. After we fixed the machine, their process became stable overnight. These three factors—rigidity, chip control, and heat—are interconnected. A lack of rigidity causes chatter, which breaks chips poorly. Poor chip control traps heat at the cutting edge, which accelerates tool wear. You have to address all three to build a robust process.

Deep Dive into the Core Factors

Let’s break down these critical factors and how they apply specifically to high-volume production. In mass production, consistency is everything.

1. Rigidity: The Stable Foundation

Rigidity comes from multiple sources. It’s a chain where the weakest link determines the outcome.

- Machine Tool: A heavy, well-maintained machine with minimal spindle runout and a solid turret is non-negotiable.

- Tool Holder: Use the shortest and thickest tool holder possible. For grooving, blade-style systems or VDI/BMT holders that clamp securely are superior. The longer the tool sticks out (overhang), the more it will vibrate. A rule of thumb is that for every 1x increase in overhang, rigidity decreases by a factor of 8!

- Workpiece Clamping: The workpiece must be held securely in the chuck or collet with minimal stick-out from the jaws. For long, slender parts, a tailstock or steady rest is essential to prevent deflection.

2. Chip Control: The Unsung Hero

In grooving, chips have nowhere to go but straight out. If they form long, stringy coils, they will wrap around the part or tool.

- Chip Breaker Geometry: Modern grooving inserts come with molded chip breakers designed for specific materials and feed rates. A "J" or "C" style geometry is common for finishing, while a tougher, flatter geometry is used for roughing.

- Cutting Parameters: Using the right feed rate is crucial. Too slow, and you get a long, stringy chip. Too fast, and you risk breaking the insert. The tool manufacturer’s recommendation is the best starting point.

- Peck Grooving: For deep grooves, programming a "peck" cycle (plunging a short distance, retracting to break the chip, and repeating) is a very effective strategy.

3. Heat Management: Staying Cool Under Pressure

Grooving generates a lot of localized heat.

- Coolant: High-pressure coolant is a game-changer. Aim the nozzles directly at the cutting edge. Through-tool coolant, where the coolant is delivered through the tool holder itself, is the best possible solution, as it flushes chips out and cools the insert simultaneously.

- Cutting Speed: Speed generates heat. While higher speeds can increase productivity, they also accelerate tool wear. The goal is to find the sweet spot that balances cycle time with tool life. Coated carbide inserts are designed to run at higher speeds than uncoated ones because the coating acts as a thermal barrier.

How Do You Choose the Right Grooving Tools for Mass Production?

Are you burning through expensive grooving inserts faster than you can replace them? In high-volume manufacturing, tool cost per part is a key metric. Choosing a tool based on the lowest initial price instead of its overall performance is a common and costly mistake that hurts your productivity.

For mass production, select a modular tooling system with tough, coated carbide inserts specifically designed for your material. Prioritize inserts with advanced chip-breaker geometries and a wear-resistant coating like PVD TiAlN or CVD Al2O3. A system with a rigid, secure clamping mechanism will minimize vibration, ensure consistency, and provide the longest possible tool life, leading to the lowest cost per part.

I always advise my clients to think about tooling as an investment, not an expense. A few years ago, a customer producing thousands of stainless steel fittings was complaining about tool life. They were using a cheap, generic grooving insert. We switched them to a premium insert from a specialized brand. The initial cost per insert was 30% higher, but it lasted four times as long and produced a better finish, eliminating a secondary polishing step. The overall cost per part dropped by 15%, and production output increased significantly. For high volume, durability and consistency trump initial price every single time.

A Strategic Guide to Tool Selection

Choosing the right tool is a multi-step process. Here’s how you can approach it systematically to ensure you get the best performance and value in a high-volume setting.

1. Analyze the Groove Itself

The geometry of the groove dictates the tool’s basic shape.

- Groove Width: The insert width should match the groove width. For very wide grooves, it’s more economical to use a narrower insert and make multiple passes (plunge-turn-plunge) than to use a very wide, expensive custom insert.

- Corner Radii: The insert must have the correct corner radii to match the print specifications. Using an insert with the wrong radius will result in a rejected part.

- Groove Profile: Is it a standard square groove, a full-radius groove, or a V-groove? Each requires a specifically shaped insert.

2. Select the Insert Grade and Coating

The material you are cutting is the most important factor here.

- Substrate: This is the base carbide material. A tougher grade (more cobalt) resists chipping in heavy roughing, while a harder grade (less cobalt) resists wear in finishing.

- Coating: The coating is a micro-thin layer that enhances performance.

- PVD (Physical Vapor Deposition): Coatings like TiAlN (Titanium Aluminum Nitride) are excellent for stainless steels, superalloys, and when you need a very sharp cutting edge. They are great for preventing built-up edge.

- CVD (Chemical Vapor Deposition): Coatings like TiCN (Titanium Carbonitride) and Al2O3 (Aluminum Oxide) are thicker and more wear-resistant at high temperatures, making them ideal for high-speed cutting in steels and cast irons.

The table below gives a general starting point for matching coatings to materials.

| Material Group | Recommended Coating | Reason |

|---|---|---|

| Steel | CVD TiCN/Al2O3 | Excellent high-temperature wear resistance. |

| Stainless Steel | PVD TiAlN or similar | Prevents material from sticking to the cutting edge. |

| Cast Iron | CVD TiCN/Al2O3 | Resists abrasive wear from the material’s structure. |

| Aluminum | Uncoated or DLC (Diamond-Like Carbon) | Very sharp edge needed; prevents material buildup. |

3. Choose the Right Tool Holder System

The holder is just as important as the insert.

- Clamping Method: Look for systems that clamp the insert rigidly on multiple faces. Screw-down clamps are common, but top-and-bottom clamping systems offer superior stability.

- Modularity: A modular system where you can swap out different heads on a single shank offers flexibility and can reduce long-term costs.

- Coolant Delivery: For high-volume work, a holder with built-in high-pressure coolant delivery is no longer a luxury—it’s a necessity for chip control and tool life.

Conclusion

In summary, achieving cost-effective, high-volume grooving requires a holistic strategy focusing on rigidity, optimized tooling, and precise process control to ensure consistent quality and maximum efficiency.