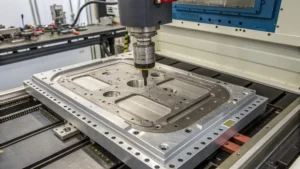

8 Essential DfM Tips for CNC Machining: Are You Making These Costly Mistakes?

Designing parts for CNC machining can be tricky. You want precision, but complex designs often lead to sky-high costs and delays. It’s frustrating when your innovative designs get bogged down by manufacturing issues or unexpected expenses, right? But what if a few simple DfM (Design for Manufacturability) tweaks could change